Wuhan Raycus Fiber Laser Technologies Co., Ltd

User Guide of Global Version 2000 W CW laser

Raycus User Guide | Installation

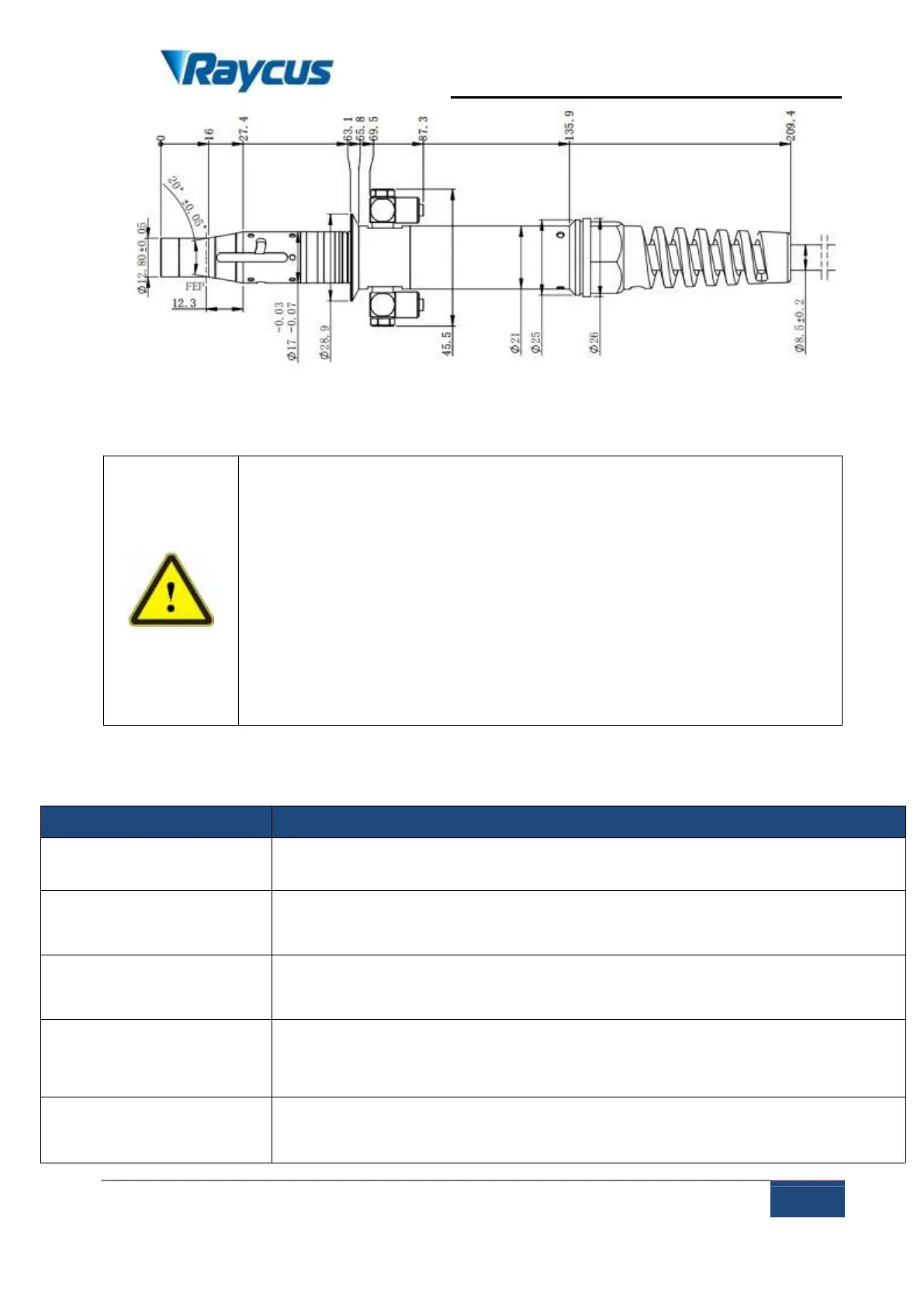

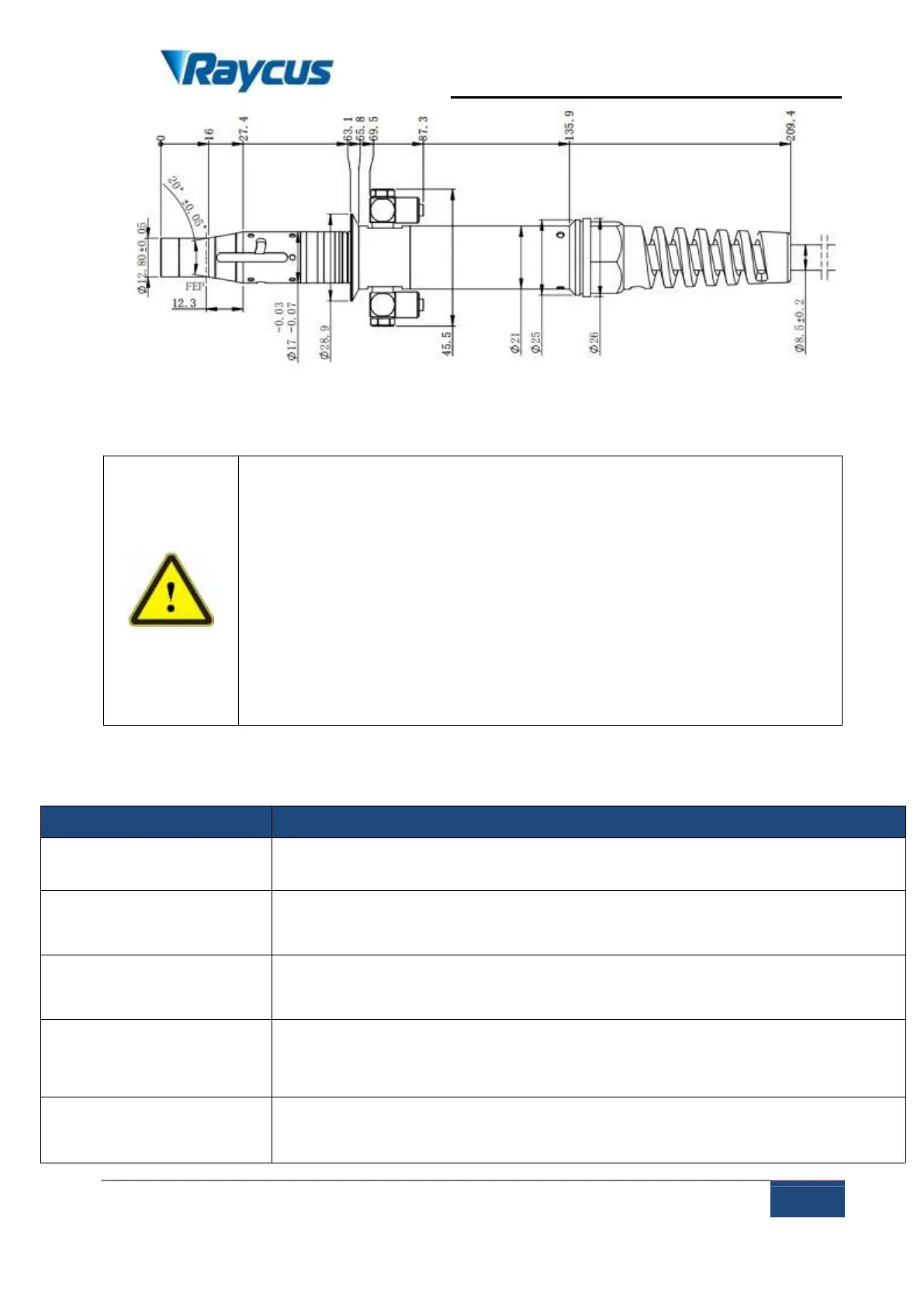

Figure 3 Dimensional drawing of handheld welding QBH output optical cable

(Unit: mm)

For QBH output optical cables, the two copper

contacts (Interlock pins) on the output head must be shorted

before the laser works, otherwise the laser will not work

properly. Usually the copper contacts are automatically

shorted after the output fiber cable is installed in the

processing equipment.

Before installing the output cable in the processing head,

the lens of the output cable must be inspected. If the lens is

dirty, it must be cleaned.

It is forbidden to disassemble the output lens by anyone

other than Raycus, otherwise the warranty will be invalidated

3.3 Cooling system installation and requirements

Table 6 Cooling Requirements

RFL-C2000S-CE/RFL-C2000H-CE

External diameter of

water-cooling pipe (mm)

Cooling system water

temperature ( C)

Loading...

Loading...