INSTALLATION

WHEEL DRIVE UNIT

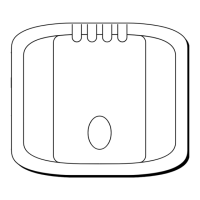

The wheel drive unit (Fig.2) is attached to

the vessel’s wheel using the clamps

supplied. To complete the installation it is

only necessary to screw the torque

restraint bracket to the pedestal. It has

been designed for permanent mounting

in the cockpit and requires no

maintenance whatsoever.

A single lever disengages drive for

manual steering.

STEERING SYSTEM

The Autohelm 4000 is designed to

operate with steering systems having

between 1 and 3.5 turns lock to lock.

Steerinq systems with more than 3.5 turns

may

ca&e

impaired steering performance

due to reduced rate of rudder application.

Lost motion in the steering system must

not exceed 1% of total movement. This is

equivalent to 7.5 degrees of free wheel

movement for a system with two turns

lock to lock. If lost motion exceeds this

level it must be corrected otherwise

steering performance will be impaired.

It is recommended that the wheel driv

L\

is not used on hydraulic steering systemi

’

Hydraulic slip across the helm pump

*-d

produces significant lost motion which

will impair steering performance.

Fig.2

WliEEICI.AMPS

I

CLUTCH LEVER

DRtVE MOTOR/GEARBOX

2

ATTACHMENT TO THE WHEEL

The drive unit is clamped to the wheel

spokes using the bolts and clamps

provided, and may be used on wheels

with 3,5 or 6 spokes (Fig. 3).

Fig.3

AI8

A holes

-

3 and 6 spoke wheels

B holes

-

5 spoke wheels

The drive unit must be mounted

between the wheel and the pedestal

(Fig. 2).

The attachment kit has three romplete

sets of clamps to compensate for differing

spoke diameters. Marked alongside each

clamp is the spoke diameter to which it

relates. The appropriate clamps are simply

broken off as required.

The spacers (Fig. 5) must be used when

the wheel is dished (Fig. 6) t9 prevent

distortion of the drive unit when the fixing

bolts are tightened.

Fig.5

SPACER

For 4 spoke wheels, use a 4.0mm

(5/32irr) drill to open out

iht>

C pilol holrs

to gain access to the additional mounting

points (Fig. 4). The plastic membrane

covering the additional nut inserts is only

1 .Omm (0.040in) thick, and care must be

tnkcn to cns\lrC that the nut inserts

arc!

ilol

ci,~tri,igotl

WIICII drilling

AI,

;Itldition~il

sol

of tlarnps

;Irld

Ml,

lot

thr

foirp

spoke is avail,Ue

IIO~TI

your Aulollgltn

stockist.

Loading...

Loading...