7

(ANSI Z223.1/NFPA 54).

The “two-opening” method requires:

1. Free combustion air 1 sq. in. per 1000 BTU input

within 12” of the floor.

2. Free ventilation air 1 sq. in. per 1000 BTU input

within 12” of the ceiling level.

Venting Connections

Drafthood (Indoor) Models 962-1826

Locate and assemble as shown in Fig. 3. Secure with

screws supplied in envelope in carton. Do not modify

the drafthood. The height of the relief openings above

the cabinet is critical to proper operation.

Models 2100-4001 have built-in drafthoods that must

be properly vented to the outside.

Vent Piping

Vent piping the same size or larger than the drafthood

outlet is recommended, however, when the total vent

height is at least ten (10) feet (drafthood relief opening

to vent terminal), the vent pipe size may be reduced

as specified in the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 - latest edition. Avoid long horizontal

runs of vent pipe and too many elbows. If installa-

tion requires horizontal or non-vertical runs, the vent

pipe must have a minimum of 1/4 inch per foot rise

and should be supported at not more than five foot

intervals. Plumber’s tape, criss-crossed, will serve to

space both horizontal and vertical piping.

Gas vents supported only by the flashing and extend-

ing above the roof more than five feet should be

securely guyed or braced to withstand snow and wind

loads. We recommend use of insulated vent pipe

spacer through the roofs and walls.

For protection against rain or blockage by snow, the

vent pipe must terminate with a vent cap which com-

plies with the local codes or, in the absence of such

codes, to the latest edition of the National Fuel Gas

Code, ANSI Z223.1/NFPA 54.

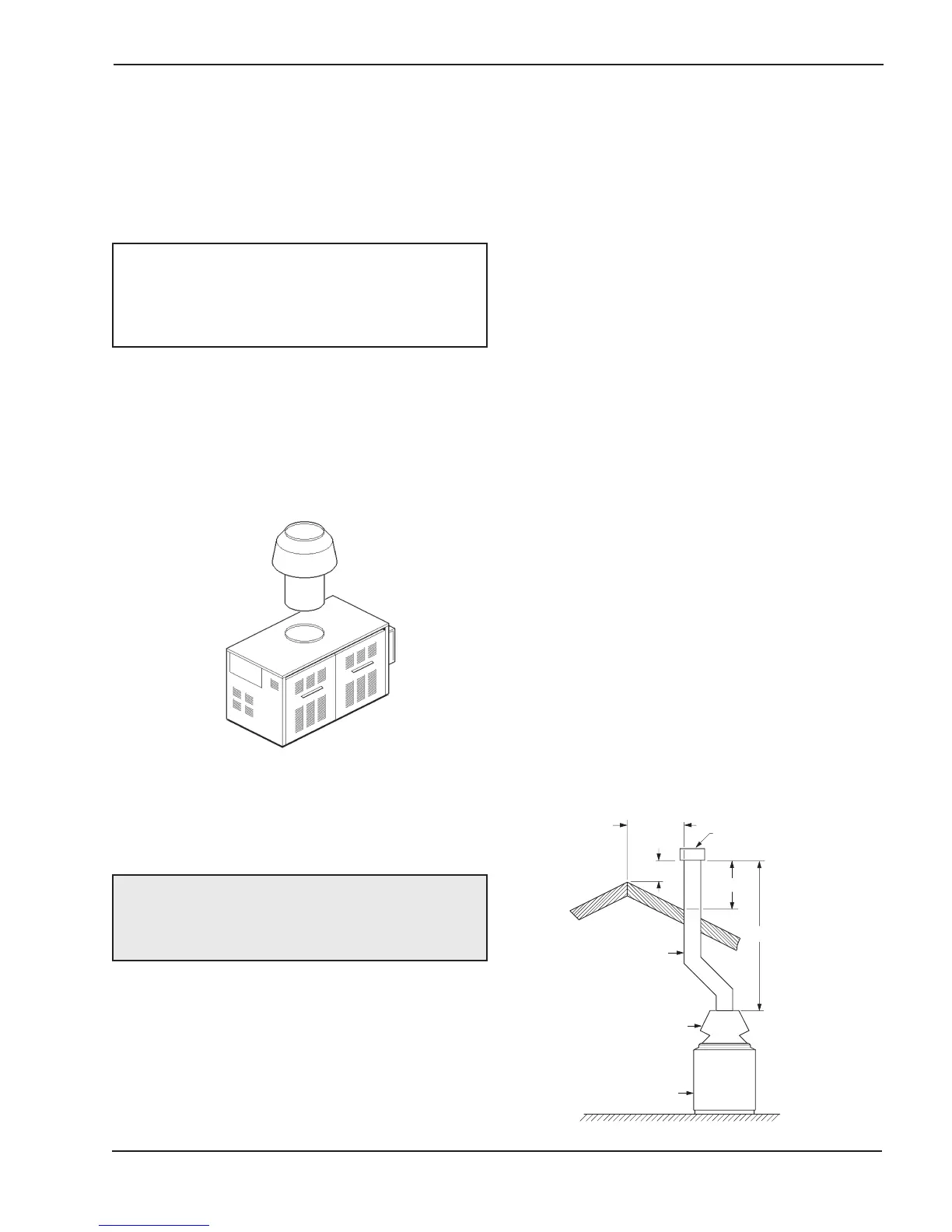

The discharge opening must be a minimum of two feet

vertically from the roof surface and at least two feet

higher than any part of the building within ten feet.

Vent stack shall be at least five feet in vertical height

above the drafthood outlet. The vent cap location shall

have a minimum clearance of 4 feet horizontally from,

and in no case above or below, unless a 4-foot hor-

izontal distance is maintained, from electric meters,

gas meters regulators and relief equipment.

The weight of the vent stack or chimney must not rest

on heater drafthood. Support must be provided in

compliance with applicable codes. The heater top

and drafthood must be readily removable for mainte-

nance and inspection. Vent pipe should be adequately

supported to maintain proper clearances from com-

bustible construction.

Type “B” double-wall or equivalent vent pipe, certified

for Category I conditions, is recommended. However,

single-wall metal vent pipe may be used as specified

in the latest edition of the National Fuel Gas Code

ANSI Z223.1/NFPA 54.

NOTE: If the room the heater is installed in is

located against an outside wall and air openings

communicate directly with the outdoors, the openings

may be 1/4 the size specified above (ANSI Z223.1/

NFPA 54, latest edition)

Fig. 3: Indoor Drafthood

WARNING: An indoor heater requires a drafthood

that must be connected to a vent pipe and properly

vented to the outside. Failure to follow this procedure

can cause fire or fatal carbon monoxide poisoning.

5' MIN

2' MIN

10' OR LESS

2' MIN

VENT CAP

VENT PIPE

DRAFT HOOD

HEATER

Fig. 4: Venting Clearances

Loading...

Loading...