22

Pumps must use a separate power supply and run

the power through a field-supplied contactor. Use

appropriately-sized wire as defined by NEC, CSA and/

or local codes. All primary wiring should be 125% of

minimum rating.

If any of the original wire as supplied with the heater

must be replaced, it must be replaced with 105°C wire

or its equivalent.

All high voltage wiring connections to the XTherm

heater are made inside the rear wiring box as shown

in Fig. 28. There are two factory-supplied pump inter-

lock relays in the rear wiring box to provide an enable

signal via dry contact (5A max) for the Boiler Pump,

Electrical Power Connections

Installations must follow these codes:

• National Electrical Code and any other national,

state, provincial or local codes or regulations hav-

ing jurisdiction.

• Safety wiring must be NEC Class 1.

• Heater must be electrically grounded as required

by the NEC.

• In Canada, CSA C22. 1 C.E.C. Part 1.

The XTherm heaters are wired for a 240 VAC, sin-

gle-phase 60 Hz power supply. Consult the wiring

diagram shipped with the heater. Before starting the

heater, check to ensure proper voltage to the heater

and pump.

• Natural Gas – 1,000 BTU/ft

3

, 0.60 specific gravity at 0.5 in. WC

pressure drop

• Propane Gas – 2,500 BTU/ft

3

, 1.53 specific gravity at 0.6 in. WC

pressure drop

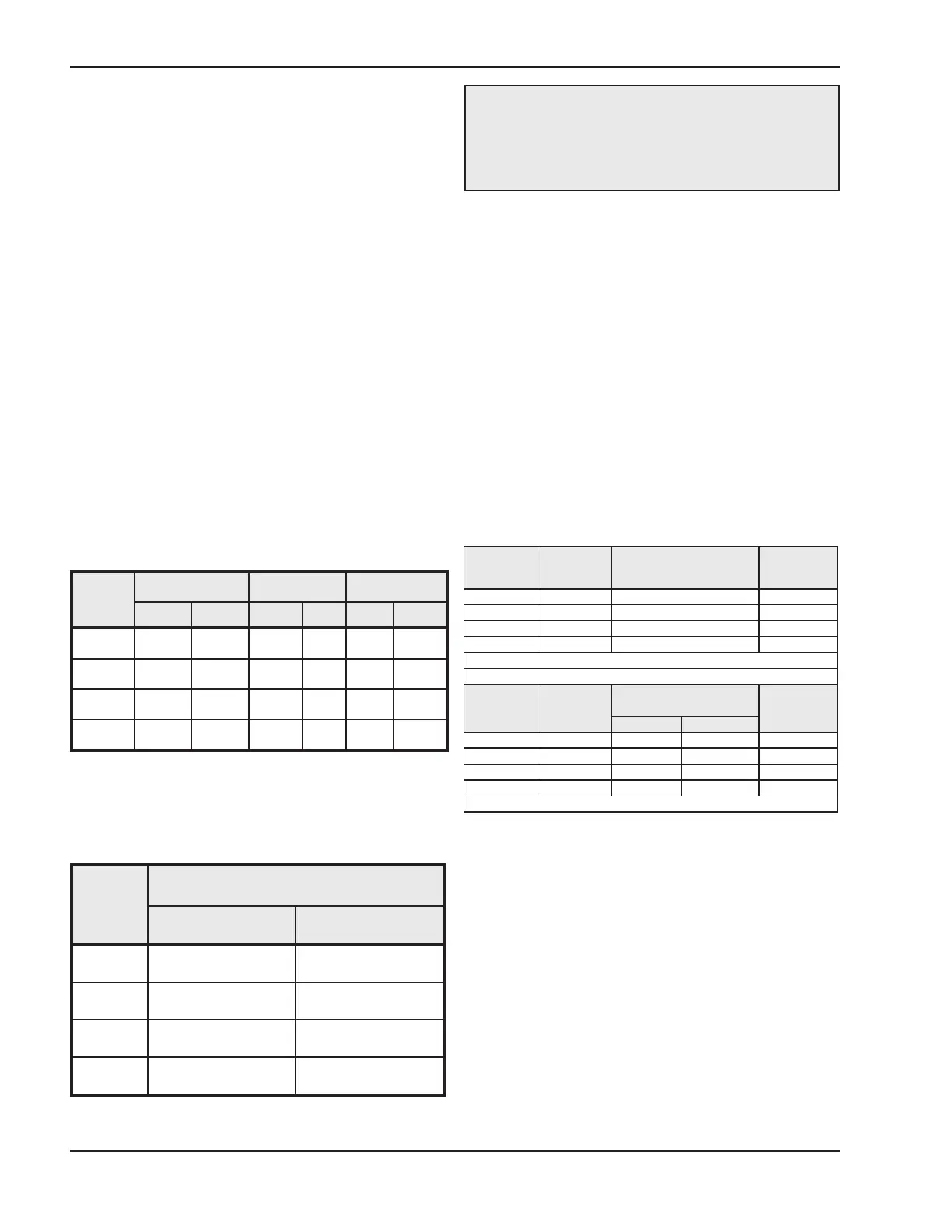

Table J: Maximum Equivalent Pipe Length

NOTE: Manifold pressures should be ±0.2 in. WC.

Table K: Manifold Gas Pressure Settings

Model

No.

2-1/2 NPT 3 NPT 4 NPT

N P N P N P

2505 55 135 160 400 600 --

3005 40 85 120 250 500 --

3505 30 45 80 200 400 600

4005 25 35 65 160 300 400

CAUTION: For proper operation, no more than

a 30% drop in gas supply pressure from no-load

to full-load conditions is acceptable. Under no

circumstances should the pressure be outside the

listed operational range.

Model

No.

Manifold Gas Pressure

(High Fire Values) (in. WC)

Natural Gas Propane Gas

2505 -4.0 -6.7

3005 -6.5 -8.5

3505 -6.1 -9.1

4005 -4.5 -8.2

Gas Supply Pressure

A minimum of 4.0 in. WC and a maximum of 10.5 in.

WC upstream gas pressure is required under load and

no-load conditions for natural gas. A minimum of 4.0

in. WC and a maximum of 13.0 in. WC is required for

propane gas. The gas pressure regulator(s) supplied

on the heater is for low-pressure service. If upstream

pressure exceeds these values, an intermediate gas

pressure regulator, of the lockup type, must be

installed.

When connecting additional gas utilization equipment

to the gas piping system, the existing piping must be

checked to determine if it has adequate capacity for

the combined load.

The gas valve pressure regulator on the heater is

nominally preset as noted in Table K.

During normal operation, carbon dioxide should

be 9.7% ± 0.5% at full fire for natural gas and

11.2% ± 0.5% for propane gas. Carbon monoxide

should be less than 100 ppm at all firing rates, mea-

sured at test port, on flue outlet adapter.

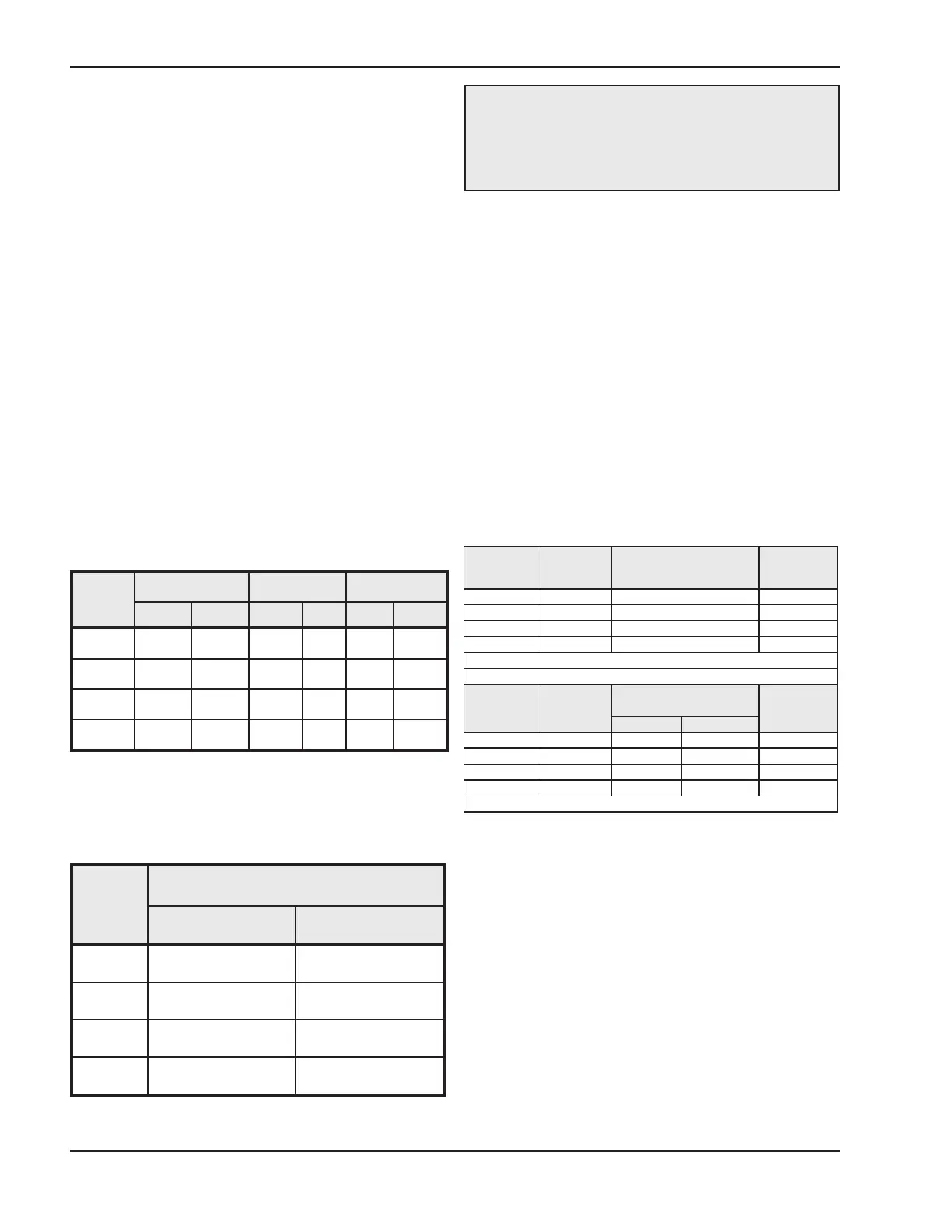

Table L: Expected Amp Draw

Model

Boiler

Amp Draw

Boiler Pump Amp Draw

Injection

Pump

Amp Draw

H7-2505 12 8.2 7

H7-3005 15 8.2 8.2

H7-3505 17 8.2 8.2

H7-4005 20 16 8.2

Amp draw at 240V/1PH

Model

Heater

Amp Draw

Heater Pump Amp

Draw

Injection

Pump

Amp Draw

Soft Med/Hard

WH7-2505 12 8.2 8.2 7

WH7-3005 15 8.2 16 8.2

WH7-3505 17 8.2 16 8.2

WH7-4005 20 16 16 8.2

Amp draw at 240V/1PH

Loading...

Loading...