22

22

Troubleshooting (continued):

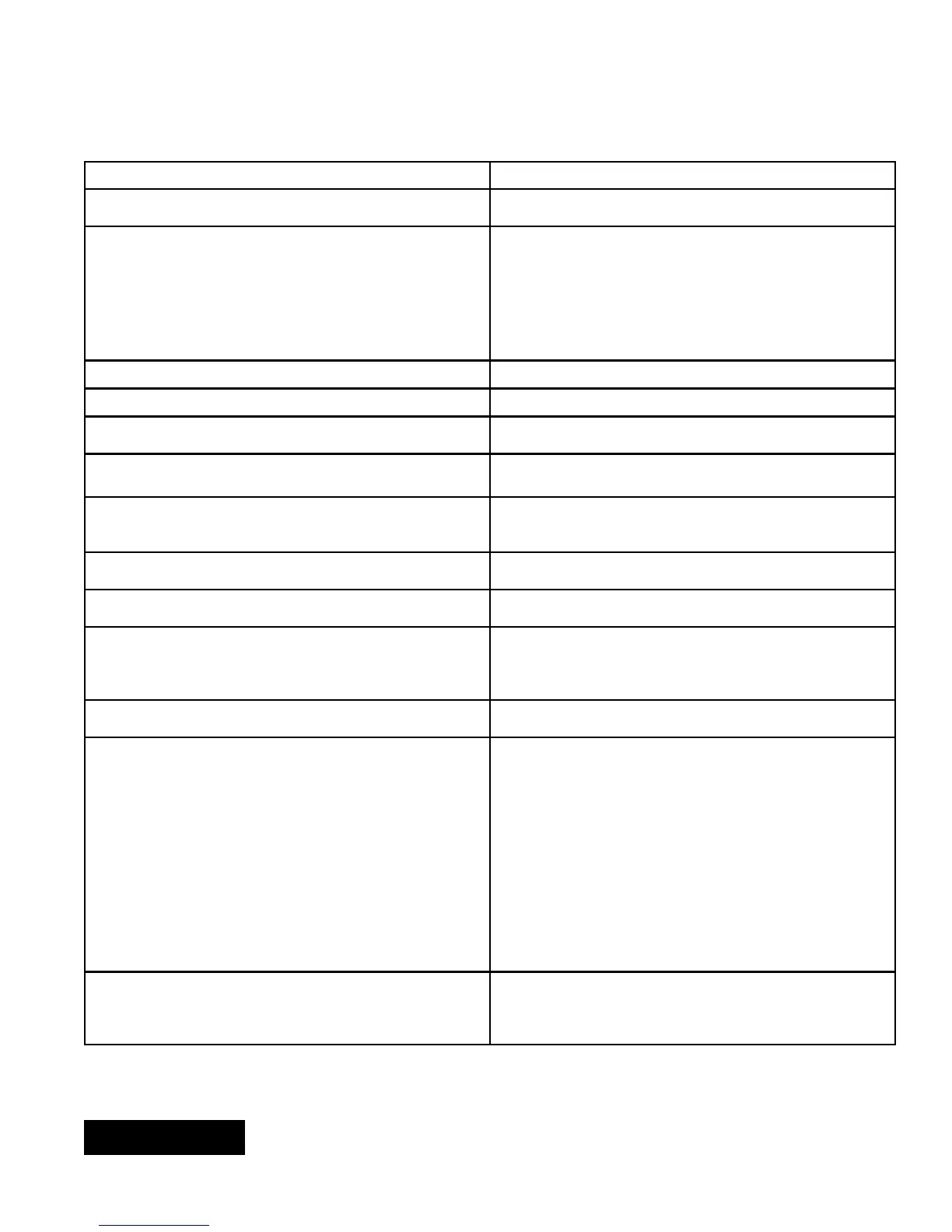

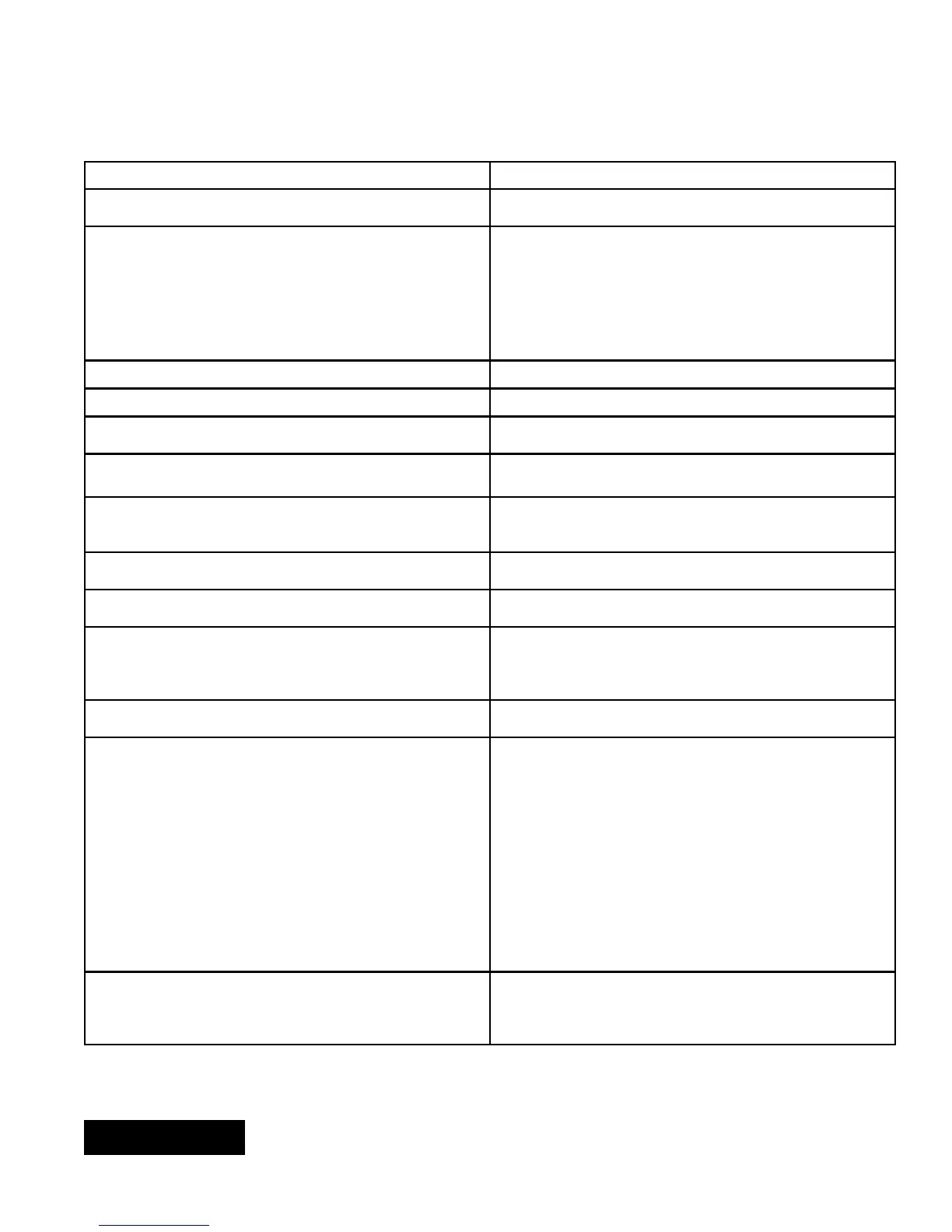

PROBLEM SOLUTION

No power Verify unit is plugged to a 120V/15 amp rated outlet and

power switch in the ON position.

Time to fill longer than expected 1. Make sure water is turned on.

2. Make sure water pressure is above 20 PSI

3. Clean out any debris at the water inlet behind the

brewer.

4. Make sure power is reaching solenoid valve and

that the solenoid valve is working. Replace

solenoid if necessary.

Refill water tank (Pour-Over model ONLY) Add water to proper level on reservoir.

Refill water tank (Auto-Fill model ONLY) Make sure that the water shut off valve is opened.

Brew volume is less than normal Adjust volume of beverage on screen. If error persists,

perform descaling procedure.

Water drips from machine when not brewing Ensure reservoir tank is not filled above maximum fill

level. Perform descaling procedure.

Water drips from machine (Pour-Over model ONLY). If Pour-Over model, ensure the water inlet valve is

capped with the cap that has been provided with the

brewer.

Water leaks from machine while brewing Remove drain tube cover and verify that the drain line is

properly plugged

Will not sense unit is primed Water conductivity is too low for level sensing circuit.

Do not use RO, DI or distilled water.

Unit will not heat Hi-limit tripped. Check and repair heating circuit to de-

termine fault before resetting hi-limit thermostat. Check

level probe has not shorted to tank to allow dry-fire.

Triac failure.

Unit overheats or boils Temperature set point too high. Reduce temperature

set point at least 5 degrees and re-check.

Capsule ruptures 1. Clogged outlet. Clean outlet probe with a paper clip

and rinse thoroughly.

2. Faulty capsule seal. Determine if isolated to

specific product capsules.

3. Sticking pressure bypass valve. Lubricate seal and

ball with food grade silicone lubricant.

4. Faulty capsule seals.

5. Soluble capsule product is not compatible with

brewer. Determine if isolated to specific product

capsules.

6. Capsule holder is not snapped into carrier correctly.

Ensure capsule holder is completely secured onto

carrier.

Clear or weak coffee is dispensed 1. Pressure bypass is leaking or stuck open.

2. Upper inlet probe is clogged. Gently insert a paper

clip into probe with caution not to disturb duckbill

check valve; run a water cycle to clear the probe.

ENGLISH

Loading...

Loading...