26

11. Operation

Fig 11.21

Fig 11.22

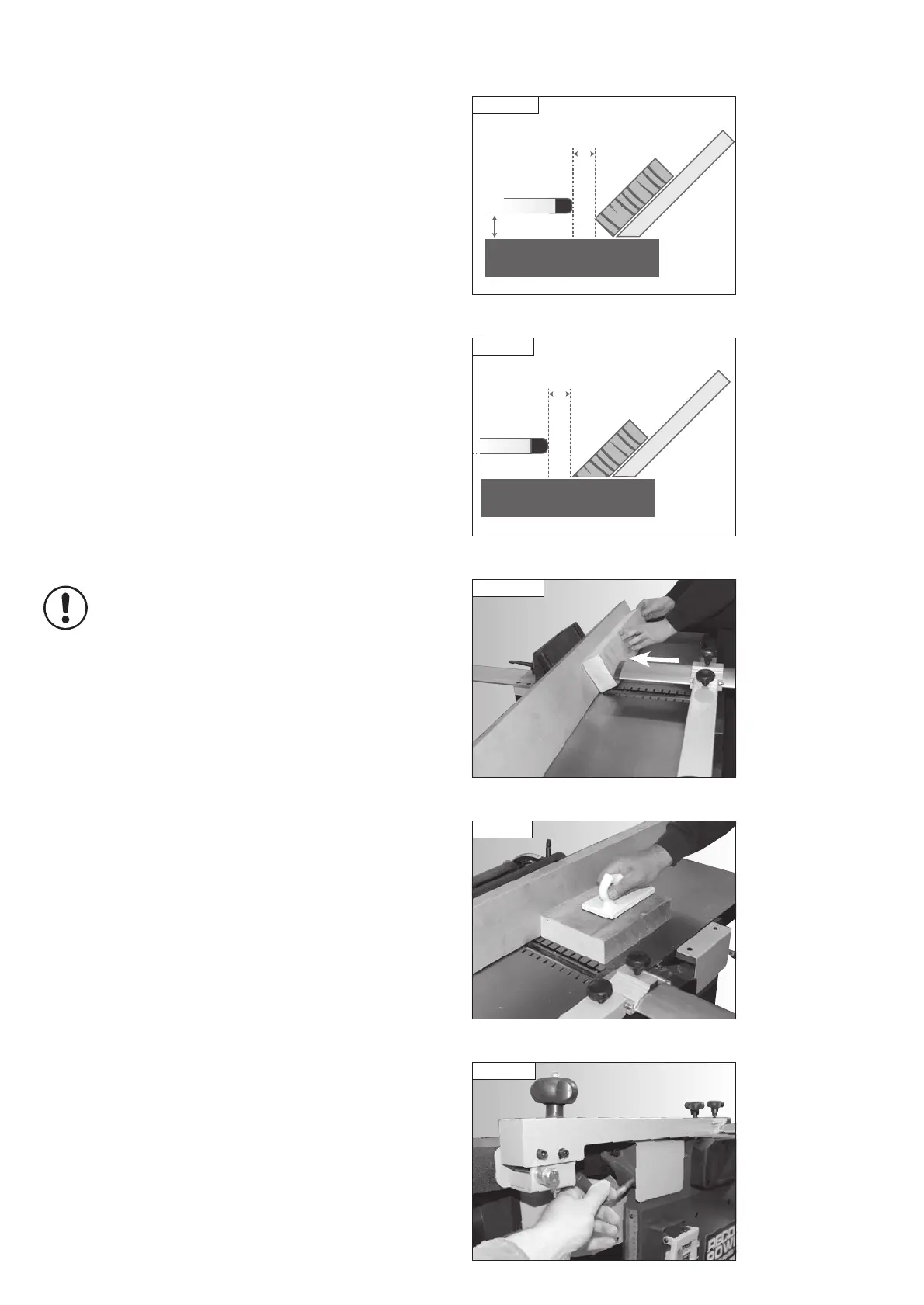

Using Additional Support

When surfacing planing small workpieces, extra care must be taken to keep

the hands a safe distance from the cutter block. If a workpiece is too small

to be held with both hands, the supplied push block can be used to hold

the timber as shown in Fig. 11.21, providing the timber is large enough to

allow the push block to sit fully upon it.

10 mm

Fig 11.19

Fig 11.20

10 mm

10 mm

Fig 11.18

When bevelling, set the bridge guard as shown in Fig 11.18 and when

tapering as shown in Fig. 11.19. Due to the nature of the cuts to be made,

the guard cannot be placed as close to the timber and cutter block as when

surface planing. However, ensure that the guard is a maximum of 10 mm

from the timber and cutter block.

Adjust the fence to required angle and press the work piece against the

fence and guide evenly over the cutterblock, Fig. 11.20.

To ensure an accurate cut and help prevent the timber slipping, press the

workpiece mainly against the fence and only lightly against the

planing table.

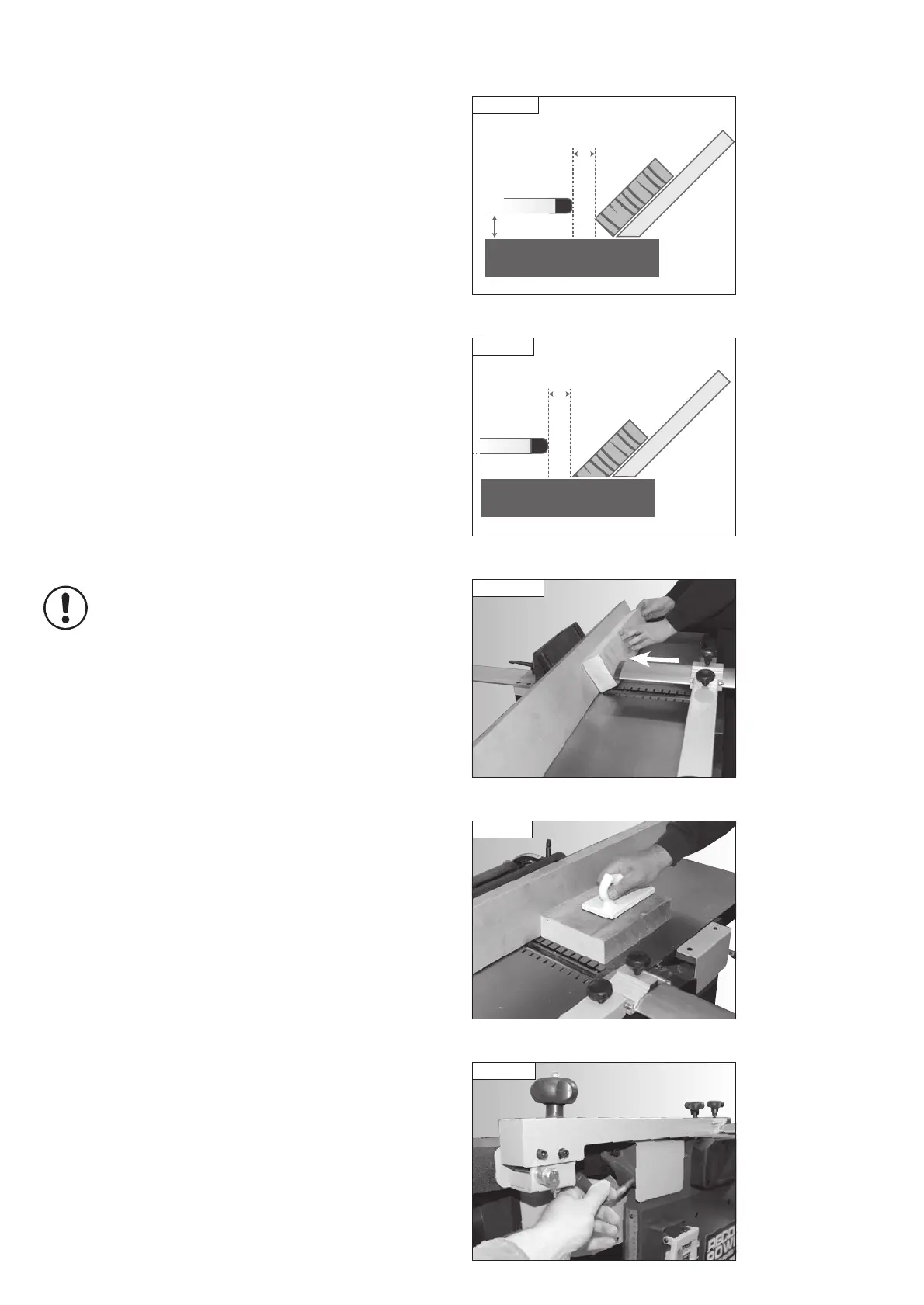

Changeover from Planing to Thicknessing

Remove the planer fence before changeover. Ensure that the

thicknessing table is at least 160 mm below the cutterblock to

allow the extraction hood to move freely between the surface

planing and thicknessing positions.

Open the table lock, Fig. 11.22, of the outfeed table, pull out the

lever fully and lift up the outfeed table.

PT107 Manual 3.2.indd 26PT107 Manual 3.2.indd 26 25/04/2022 14:43:2025/04/2022 14:43:20

Loading...

Loading...