27

Fig 11.23

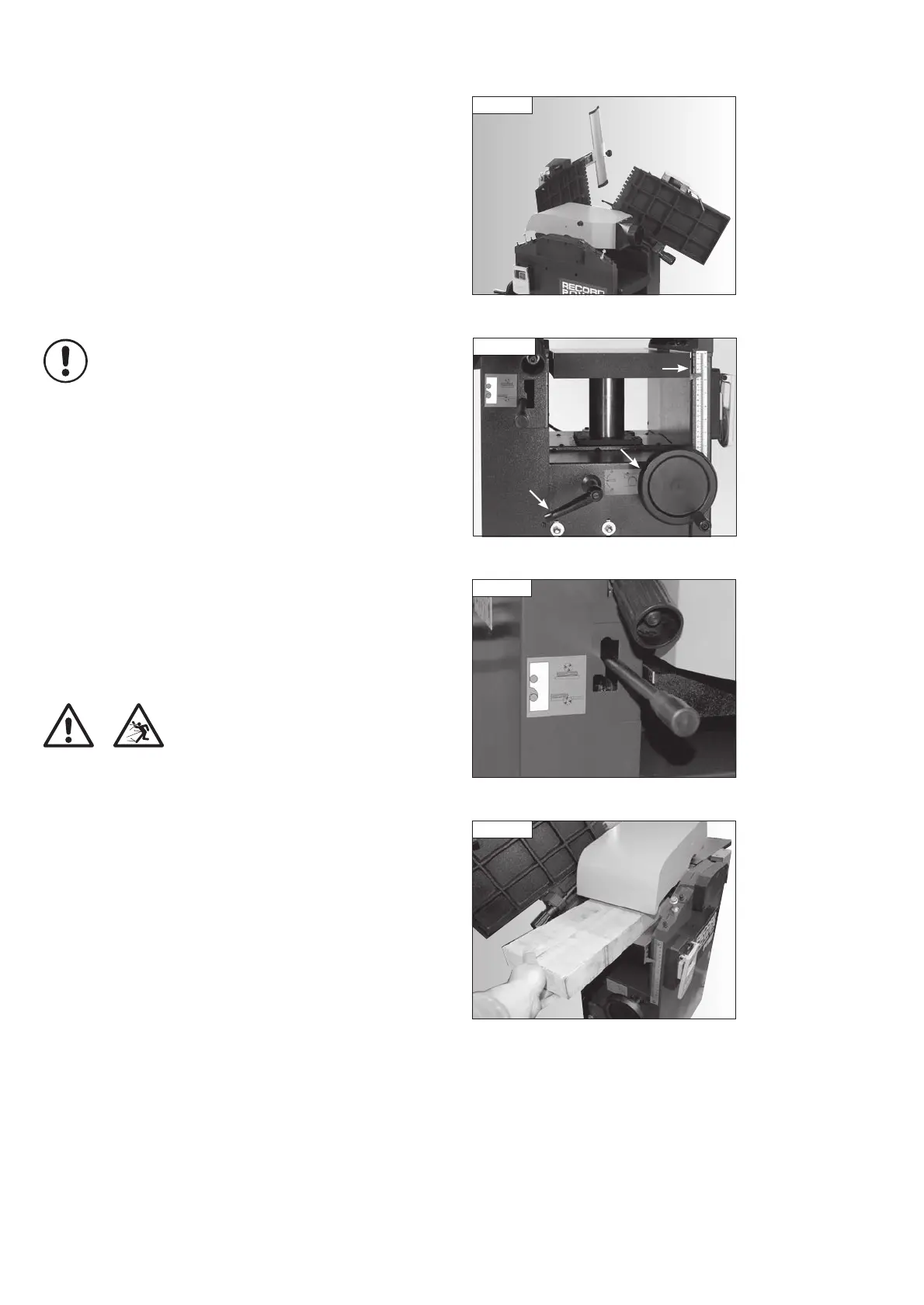

Fig 11.24

Lock

lever

Depth scale and

pointer

hand wheel

Thicknessing

Adjust the thicknessing table height to that of the workpiece height, minus

the depth of cut required.

Ensure the feed clutch is in the upper position as shown in Fig 11.25.

Turn the machine on and carefully slide the work-piece onto the thicknesser

table until it is drawn in by the feed rollers, Fig. 11.26. Keep hands as far

away from the cutter block as possible.

Warning: If the workpiece becomes trapped when feeding

into the thicknesser, immediately switch the machine off and

disconnect from the power before attempting to free the

workpiece. To release the workpiece, lower the

thicknessing table.

Restarting

In the Event of a Blockage or if the Machine Stalls

If the machine stalls due to the work piece becoming trapped in the cutter

block, switch it off immediately by pressing the emergency stop button (Red

button marked ‘O’) and wait for the machine to come to a complete stop

before proceeding further.

If the work piece is trapped between the cutter block and thicknessing table,

it may be necessary to lower the thicknessing table in order to free

the blockage.

To re-start the machine, press the green button marked ‘I’ on the switch.

In the Event of a Power Failure

The machine is fitted with a no volt release (NVR) switch to protect the user

against automatic starting of the machine when power is restored after a

power failure.

In the event of a power failure, first locate and rectify the source of the

failure. If the fault is within the power circuit of the workshop, there may be

an underlying cause (circuit overload etc.) that should be investigated by

a qualified electrician, before attempting to restore the power source. If a

cutting operation was taking place when the power supply was interrupted,

then it may be necessary to free the work piece from the cutter before

attempting to re-start the machine.

Once the power is restored, the machine can be re-started by pressing the

'on' switch.

11. Operation

Fig 11.26

Fig 11.25

Be sure the outfeed table is fully raised and tilted, Fig. 11.23.

Now raise the infeed table in the same manner.

Finally, raise the extraction hood to cover the cutter block, Fig 11.23.

To return the machine to planing mode follow the above instructions in

reverse order.

Adjusting the Height for Thicknessing

Unscrew the lock lever that clamps the thicknessing table, Fig 11.24.

Now adjust the thicknessing table to the required height using the hand

wheel, Fig 11.24. The depth scale and pointer to the right of the hand wheel

indicate the table height.

Retighten the lock lever to clamp the table in place.

Attention: The depth of cut should be minimised under the following

circumstances:

• The timber is very wide.

• The timber is hard wood.

• The timber is damp.

• The planer blades are in need of sharpening.

PT107 Manual 3.2.indd 27PT107 Manual 3.2.indd 27 25/04/2022 14:43:3225/04/2022 14:43:32

Loading...

Loading...