33

12. Adjustments & Maintenance

Drive belts

Over time the drive belt may loosen slightly. In this case, the belt must

either be tightened or replaced. Check the belt regularly for cracks or lateral

tears and replace it if necessary.

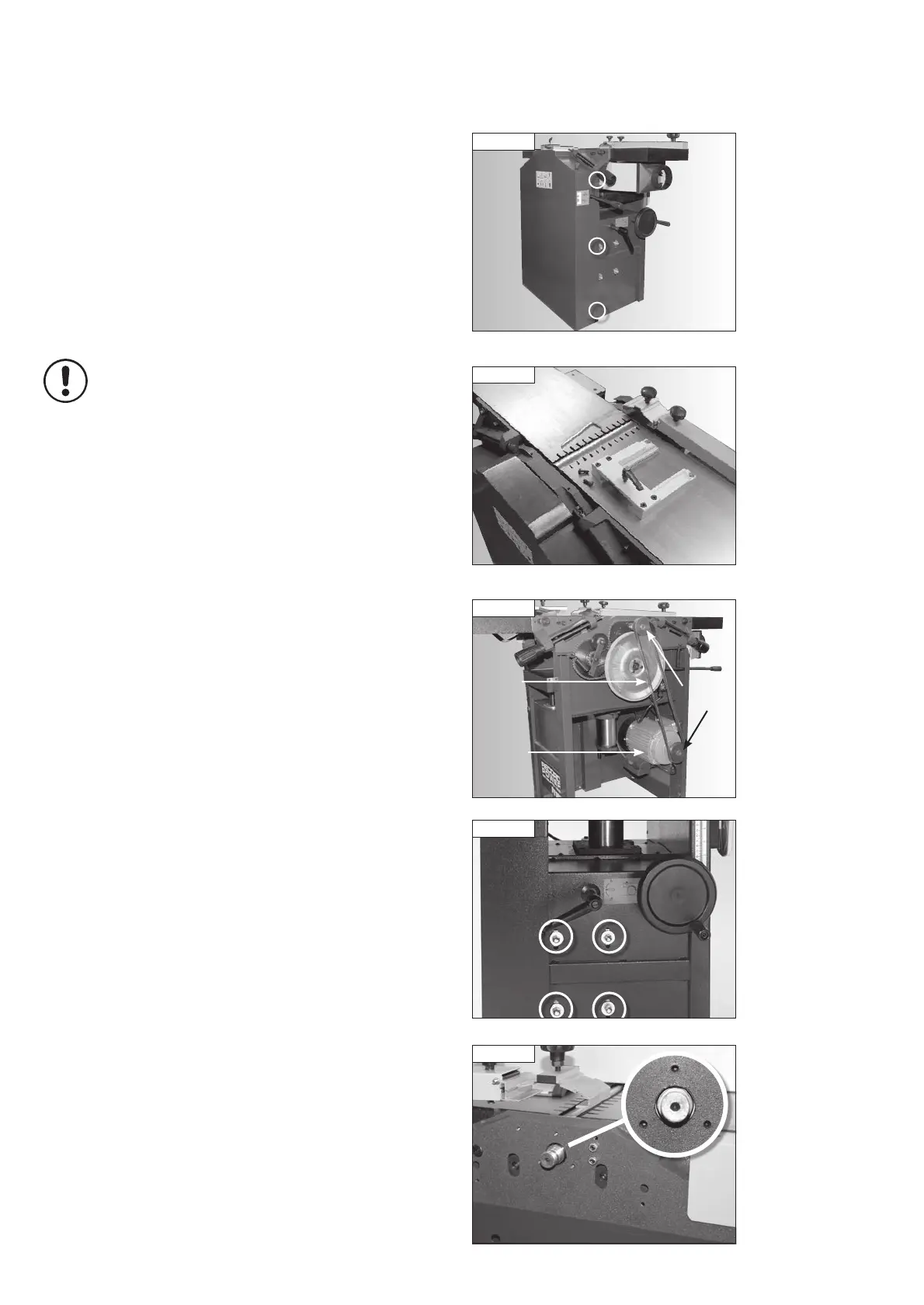

To access the interior of the machine, remove the 6 screws (3 on either side

of the machine) as shown in Fig 12.17.

In addition, the fence carrier must be removed, Fig. 12.18.

The side panel can now be removed by lifting upwards slightly and then

away from the machine, Fig 12.19.

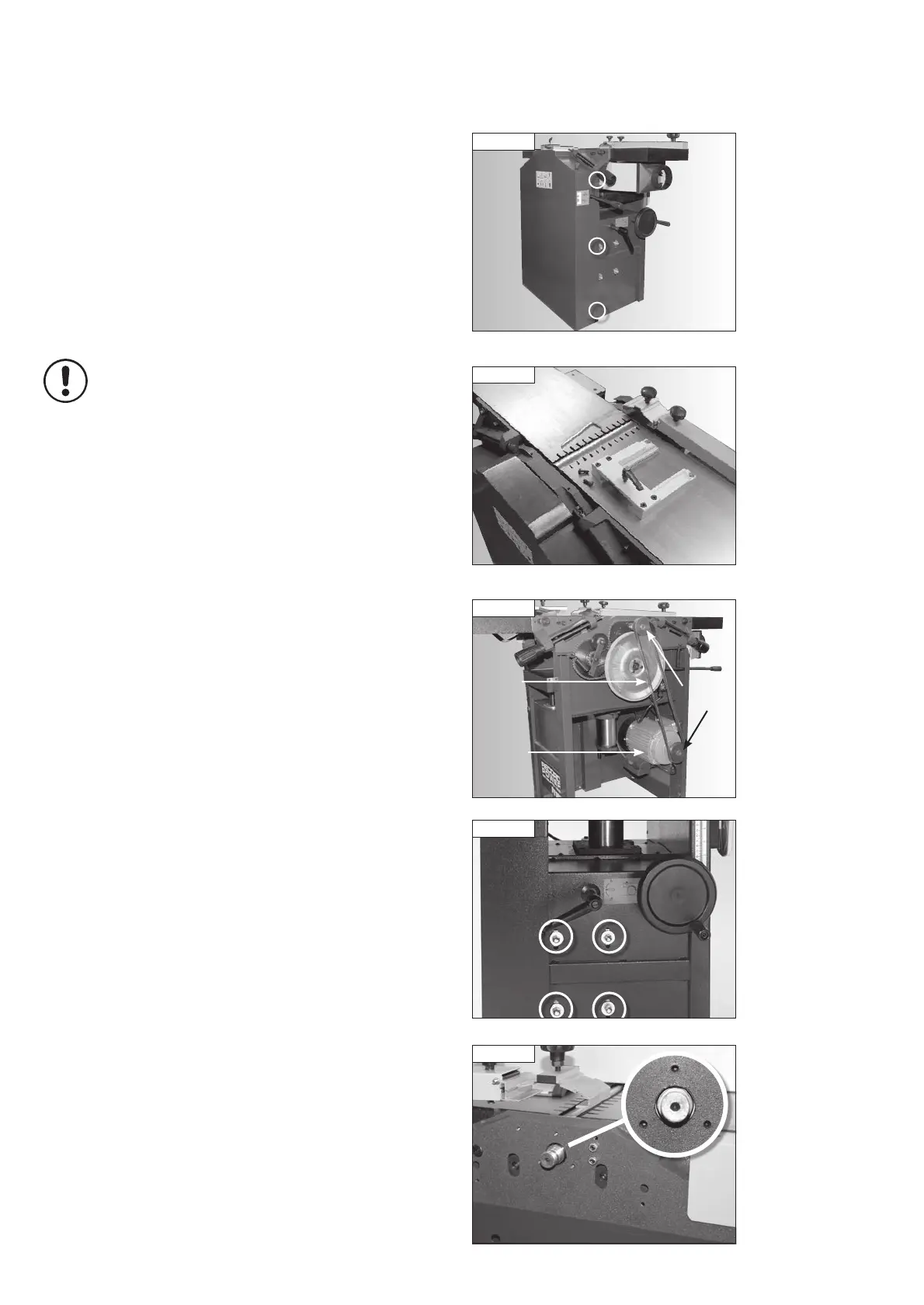

Loosen the motor mounting bolts on the side of the machine, beneath the

outfeed table, Fig 12.20.

Use the weight of the motor to tension the drive belt. When the correct

tension is applied, tighten the motor mounting bolts.

When re-positioning the motor to apply tension, ensure it is

kept level in the horizontal plane. Also ensure both pulleys

are aligned.

Cutter Block Bearings

After prolonged use the bearings of the cutter block may become slightly

loose and need tightening. To do so, remove the spindle cover from the side

of the machine and adjust the 3 blind set screws shown in Fig. 12.21 with

a 3 mm hex wrench. This will adjust only the bearing on that side of the

cutter block. However, the amount of movement that is likely to occur is so

small that under normal circumstances adjustment of this bearing only will

be sufficient. When tightening the blind set screws, only minimal adjustment

is needed. Turn them each 1/8 of a turn at a time and stop when resistance

is felt. In the highly unlikely event that the other bearing needs adjustment,

please contact Record Power customer services in your area.

Fig 12.17

Fig 12.18

Fig 12.21

Fig 12.19

Motor

Drive

belt

Pulleys

Fig 12.20

PT107 Manual 3.2.indd 33PT107 Manual 3.2.indd 33 25/04/2022 14:44:2025/04/2022 14:44:20

Loading...

Loading...