-30-

Drawing No. LP0932 Released 2018-01-12

6-Pr

PROFILE

DEVIATION

ERROR VALUE

PROFILE

DEVIATION

ERROR TIME

VALUE

START-UP

RAMP RATE

PROFILE

PROFILE

ENDING

SEGMENT

y

PROFILE

SEGMENT

SETPOINT

y

PROFILE

SEGMENT

TIME

PROFILE

CYCLE

COUNT

PROFILE

LINK

P

P

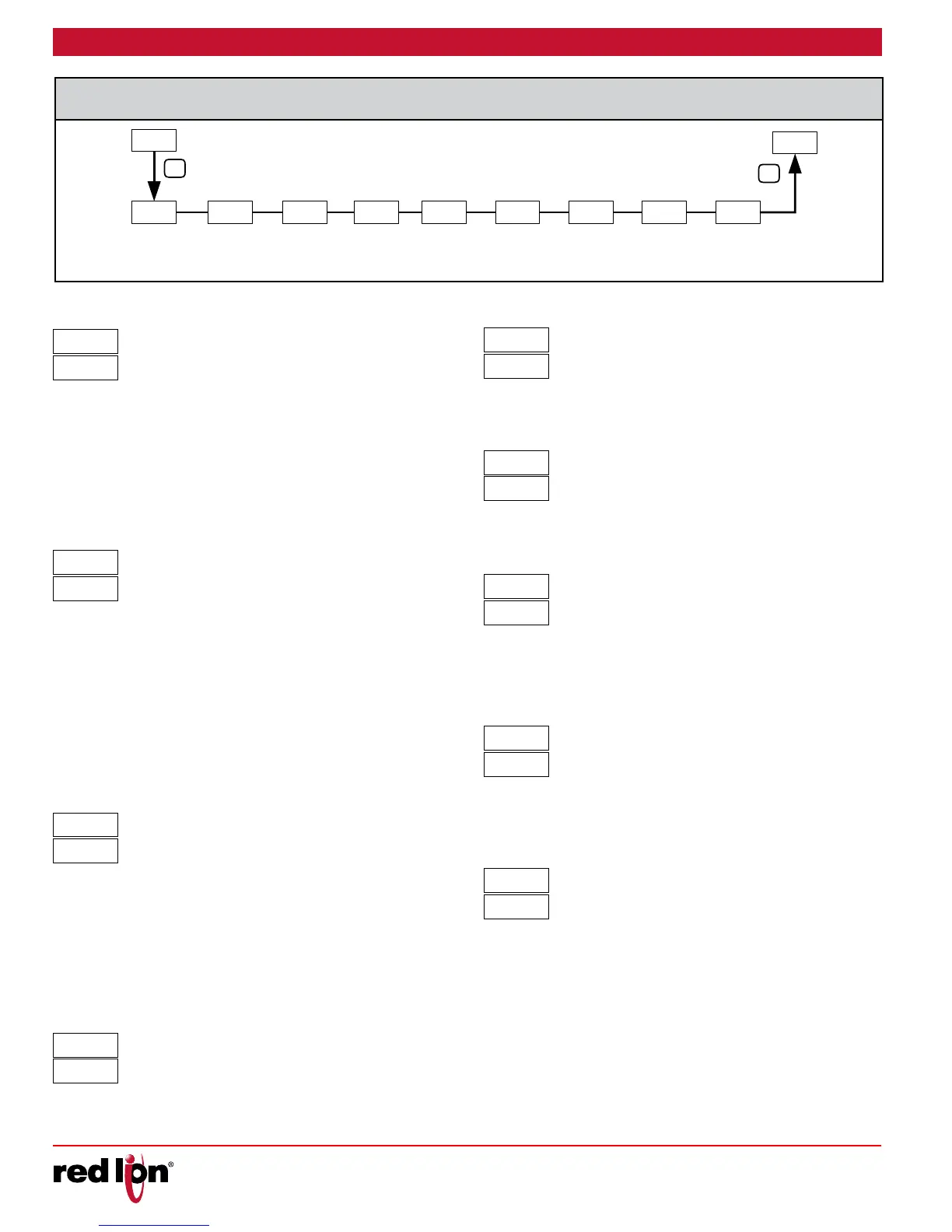

Select desired profile to edit (0 thru F). When a profile is running, the

currently running segment setpoint or time value should not be changed,

however, other segments may be changed.

0 to 100.0

Profile process value conformity can be assured by using the profile

Error Value parameter. If the process value deviates outside the error

band (SP – ) while a profile is running, the controller enters the delay

mode. In the delay mode, the time base of the profile is held (delayed)

until the process value is within the deviation error band. At this time, the

profile continues running unless the process value again deviates.

These actions ensure that the actual process value conforms to the

profile.

0.0 to 999.9 minutes

When the profile enters delay mode due to the process value being

outside the Profile Error Band, a Profile Error timer starts. If the process

value remains outside the error band and the timer exceeds the Error

Time Value, the Profile Error Band Timeout flag, Pt, is set. The Alarm

output(s) can be configured to activate based on the Pt flag condition.

See 4-AL Alarm Action for more information. The flag (Pt) is cleared

when the profile is manually stopped; the profile is manually advanced

to the next segment; the profile is put into run state after being paused;

or when a profile is started. A value of 0 disables Error Band Timeout

Flag operation. See “Error Band Delay Mode Timeout” in the “Profile

Overview” section.

0.1 to 100.0 display units/minute

The Start-up Ramp Rate is used to reduce sudden shock to a process

during setpoint changes and system startup. A start-up ramp rate is used

to move the Target Setpoint at a controlled rate. The value is entered in

display units/minute. If the Ramp Rate is enabled, and the Setpoint

value is changed or the controller is powered up, the controller sets the

Target Setpoint to the current process measurement, and ramps to

setpoint. (In a properly designed and functioning system, the process

will have followed the Target Setpoint value to the Setpoint value.)

NO 0-9 and A-F

Select the last segment to be implemented within this Profile.

0 to 15

Select setpoint for profile x segment y.

0-9 and A-F

Select profile x segment y time.

Repeat the above two parameters for Px0, Ix0 thru PxF, IxF

0.0 to 999.9 minutes

Select the number of times that this Profile should repeat/cycle. Select

0 for continuous cycling.

0 to 99

Select the action that should take place when the profile has

completed the programmed number of cycles. Selection includes linking

to profile 0 thru F, end profile and continue controlling at current setpoint,

or stop output control.

0 to F Nd OP

0.0

r-V

0.0

r-

0.1

RP

NO

ProF

Nd

LINx

12

CYCx

200.0

Ixy

200.0

Pxy

15

Ndx

Loading...

Loading...