PRODUCT DESCRIPTION

Models

4

PRODUCT DESCRIPTION

This submersible pump is for use in basins or lift stations and is suitable for pumping clear water and other

non-explosive, non-corrosive liquids. Do not use the pump in applications where sewage or any other debris

(gravel, sand, floating debris, etc.), abrasives, or corrosives are present.

These products have been carefully tested, inspected, and packaged to ensure safe delivery and operation.

Please examine your pump carefully to ensure that no damage occurred during shipment. If damage has

occurred, please contact the place of purchase. They will assist you in replacement or repair, if required.

The pump motor is equipped with an automatic resetting thermal protector, and may restart unexpectedly.

Thermal Protector tripping is an indication of motor overloading or overheating, which can be caused by

application issues such as an obstructed pump impeller, float stuck in the ON position, pump running dry,

pump air-locked, pump short cycling, excessively high or low voltage supply, or possibly a pump, motor,

bearings, or seal that have reached the end of their useful life.

Models

Flow Rates

Specifications

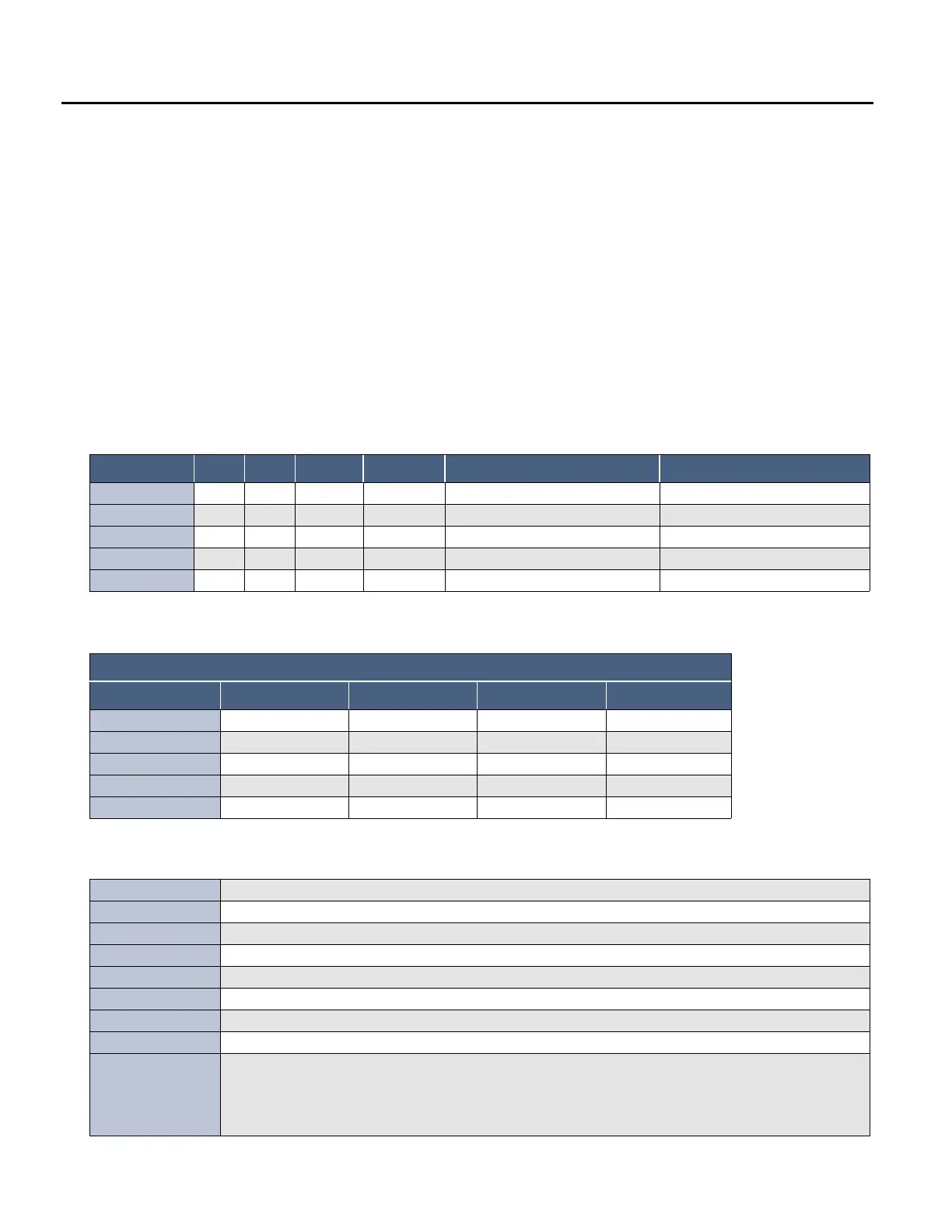

Model HP Amps Voltage Float Type On/Off Levels Minimum Basin Diameter

RL-SP25T 1/4 6 115 Tethered 14.5” (368 mm)/5.5” (140 mm) 14” (356 mm)

RL-SP33T 1/3 4.4 115 Tethered 14.5” (368 mm)/5.5” (140 mm) 14” (356 mm)

RL-SP33V 1/3 4.4 115 Vertical 7.25” (184 mm)/2.75” (70 mm) 11” (279 mm)

RL-SP50T 1/2 5 115 Tethered 14” (356 mm)/6” (152 mm) 14” (356 mm)

RL-SP50V 1/2 5 115 Vertical 7.25” (184 mm)/2.75” (70 mm) 11” (279 mm)

Gallons/Liters per Hour

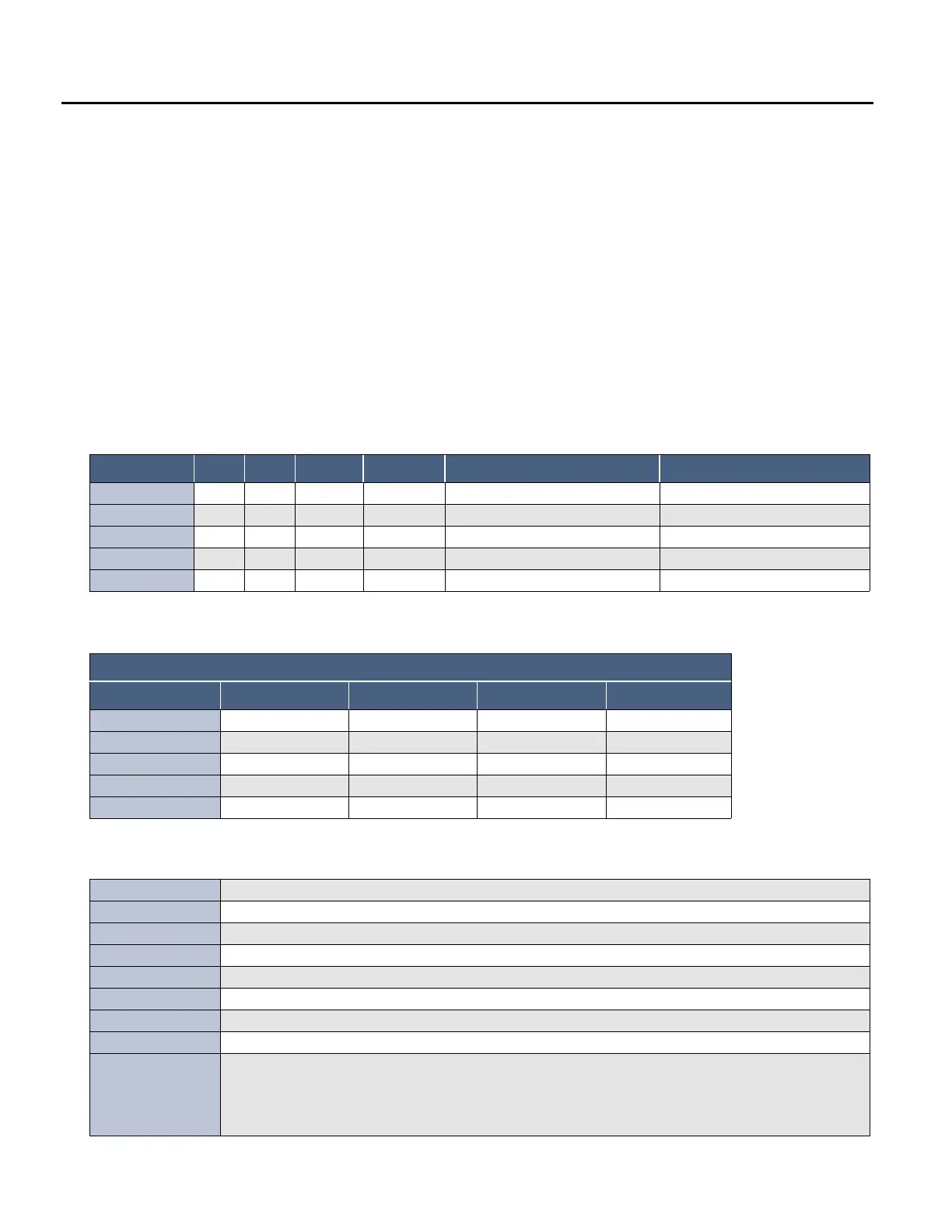

At Height: (Head) 5 ft (1.5 m) 10 ft (3 m) 15 ft (4.5 m) Shut Off

RL-SP25T 2640 / 9993 2100 / 7949 1560 / 5905 23 ft (7 m)

RL-SP33T 2880 / 10,902 2340 / 8858 1680 / 6359 25 ft (7.6 m)

RL-SP33V 2880 / 10,902 2340 / 8858 1680 / 6359 25 ft (7.6 m)

RL-SP50T 3060 / 11,583 2520 / 9539 1920 / 7268 28 ft (8.5 m)

RL-SP50V 3060 / 11,583 2520 /9539 1920 / 7268 28 ft (8.5 m)

Discharge Size 1-1/2" FNPT

Intake Size 1/8" (3.2 mm) screened opening

Pump Housing Thermoplastic (including volute and screen)

Impeller Vortex design

Motor Single phase PSC with automatic reset thermal overload protection

Hardware 300 series stainless steel

Bearings Ball bearings

Pump Shaft Seal Mechanical, spring-loaded, stationary carbon with Nitrile boot and rotating ceramic seat

Cooling

The motor housing contains oil to cool the motor and to lubricate the bearings and seals. These pumps can

be operated with the motor housing partially exposed for extended periods of time. However, for the best

cooling and longest motor life, the liquid level being pumped should normally be above the top of the

pump housing.

Loading...

Loading...