Page | 4 Ascento 37 Export St Lytton QLD PH: 1800 807 604 | VSRM Inverter Contant Pressure Pumps | V2016.12

3. Installation and Operation instruction

IMPORTANT NOTICES: READ BEFORE INSTALLATION

3.1 IMPORTANT MANDATORY INSTALLATION REQUIREMENTS:

1. IMPORTANT: a Check-Valve must be installed in the inlet pipe

2. IMPORTANT: Install using Barrel-Union connections for easy removal for repair or servicing. Install a Y-Strainer or

Pre-Filter and also a Ball-Valve on the inlet piping. REFER to the Diagrammatic Instructions for more information. No

warranty applies if these are not fitted according to the instructions.

3. IMPORTANT: Pressure setting in the Pressure Tank MUST be changed, once the OPERATING PRESSURE is

decided/set. Firstly set the OPERATING PRESSURE (“Setting” on the keypad), then adjust the pressure in the

PRESSURE TANK, recommended to be set at 50% to 70% of the OPERATING PRESSURE (“Setting” on the keypad)

3.2 IMPORTANT NOTE: Pressure of the water at the discharge (taps, showers, irrigation etc) is affected by the pipe

size. The SMALLER your pipes, the LOWER the pressure will be at discharge. Example: 13mm ID pipe over 20 metres

at 30Lpm will reduce pressure at discharge by 240kPa (2.4bar) - whereas if 25mm ID pipe is used for 20 meters at

30Lpm it only reduces pressure by a miniscule 10kPa. Smaller pipe also means that more power will be used as the

pump has to work harder to overcome the extra back-pressure from small pipes. A small short-term saving (in the

cost of the pipes) will become a long-term liability.

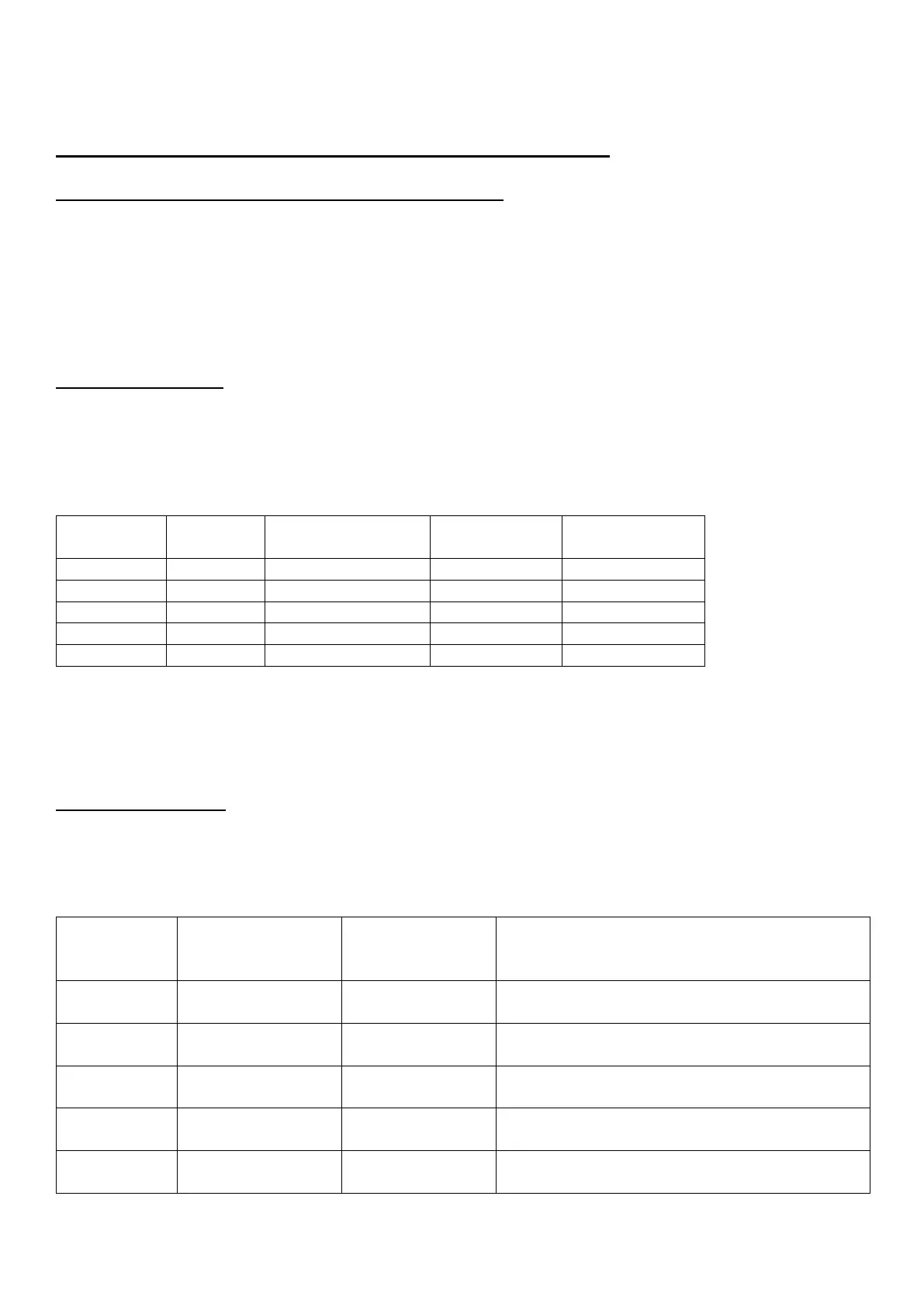

Inlet Pipe (Suction

Pipe) ID

The larger size is recommended for best performance.

Pipe sizes are ID (Internal Diameter). We do not recommend 18mm Copper pipe is used for the main discharge for

these pumps – we recommend the larger sizes as per the chart above, is used for the main supply lines – smaller

pipes then can be used to connect to the fixtures.

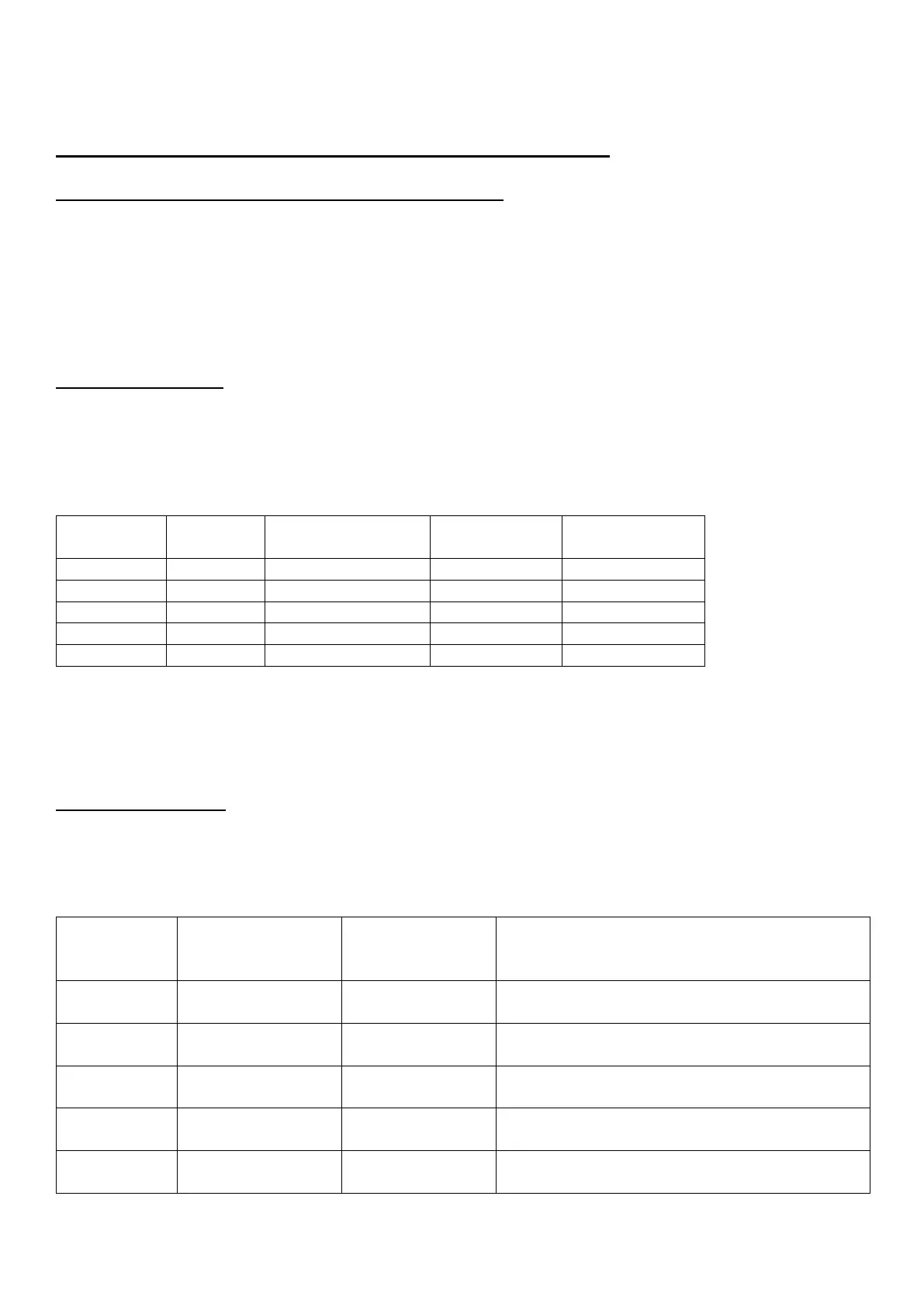

3.3 IMPORTANT NOTE: The higher the Pressure setting (“Setting Pressure” on the pump control panel) the more

power you will use – set the pressure at the lowest pressure that is acceptable for the application. The

recommended setting is 65% of the max head pressure and the MAXIMUM setting is 80% of the max head pressure

(refer to the label on the pump and also the table below) IF THE PRESSURE IS SET TOO HIGH THE PUMP WILL RUN

CONTINUOUSLY – this will cost you a lot of wasted power and void the warranty.

Recommended

Pressure Setting for

flooded suction

Maximum Pressure

setting for flooded

suction

Maximum Pressure setting for Mains boosting

3.0Bar above existing mains pressure

(cannot exceed 10.0Bar)

4.0Bar above existing mains pressure

(cannot exceed 10.0Bar)

3.0Bar above existing mains pressure

(cannot exceed 10.0Bar)

4.9Bar above existing mains pressure

(cannot exceed 10.0Bar)

4.0Bar above existing mains pressure

(cannot exceed 10.0Bar)

Loading...

Loading...