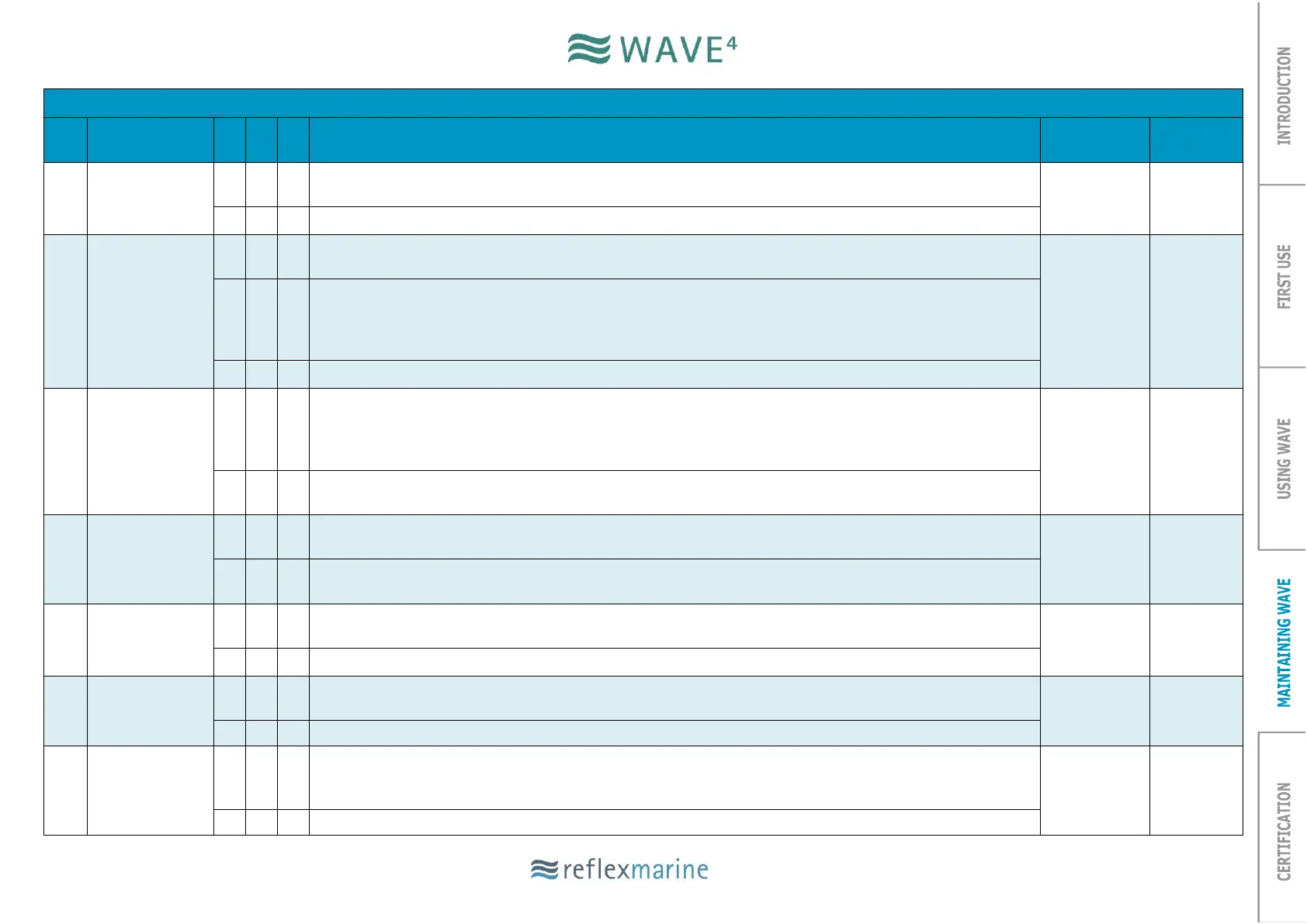

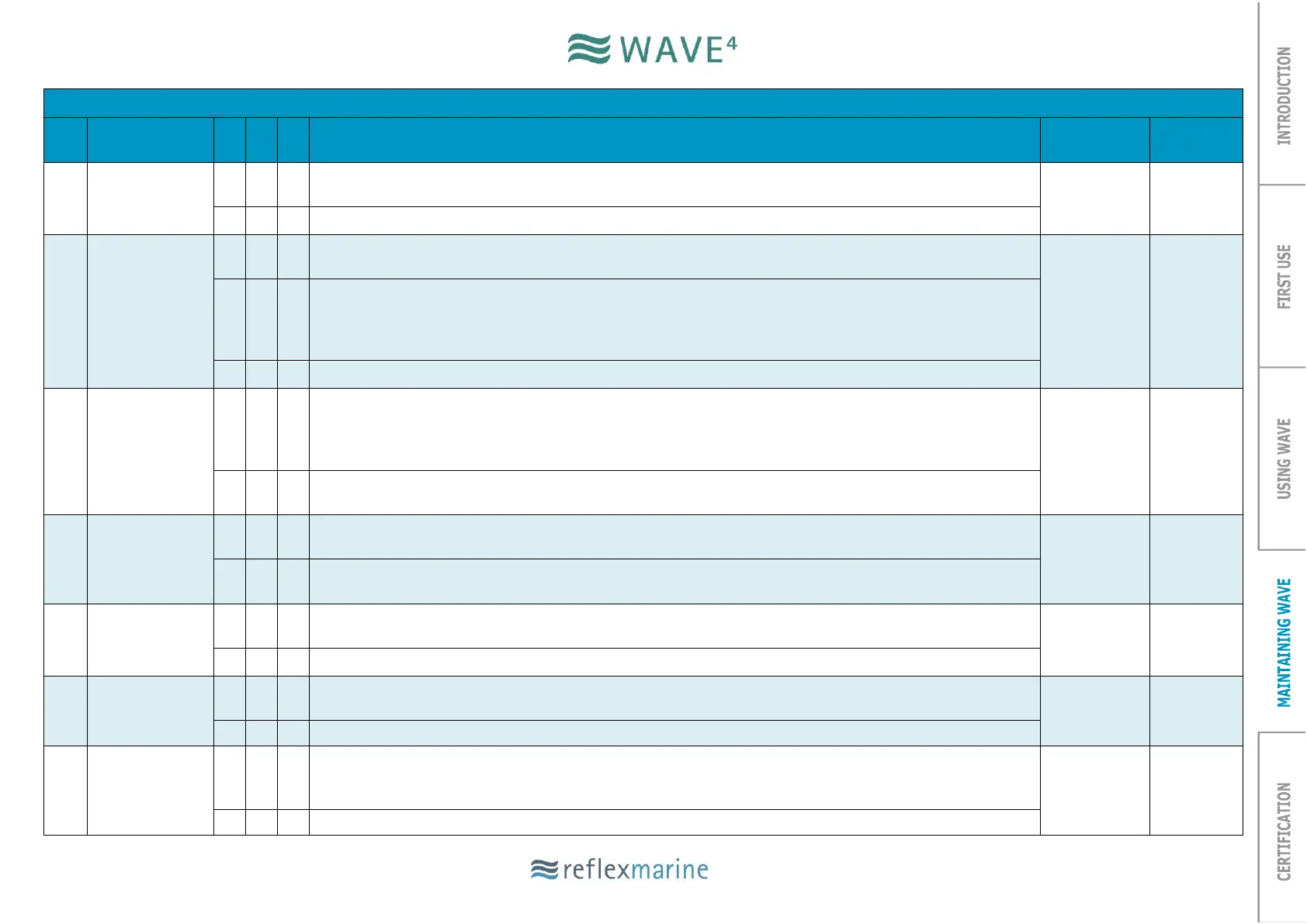

WAVE Inspection checklist form (Page 2/3)

Lower Node

Plate

(Critical Part)

Check securely fastened and for any signs of damage. Record Serial Number against certificates in

comments

Tools Required: Optional: Forklift/Overhead Crane

Node Plate

Safety Bolts

(Critical Part)

(Consumable)

Check for damage. Check split pins and tamper proof seals are fitted, and nuts are securely fastened.

Replace items where required. Record Colour Code against certificates in comments.

Remove and inspect thread and nuts for damage. To avoid the central column shifting position remove

only 2 bolts at one time. Depending on the usage level, you might need to replace these bolts. If bolts

are being re-used, clean threads and lubricate with copper grease. Replace split pins, nuts and tamper

proof seals. Note: Tighten to 45Nm.

Tools Required: 2x 17mm Spanners, Inspection Stands. Optional: Forklift/Overhead Crane, Hammer

Check that the bottom and top attachment points are secure and free from damage. Check ropes are

not frayed or overly faded. Check tension of each restraint: they should be tight enough to allow the

passenger to lean against the restraints, but not so tight that they made entry difficult. Note: The

length of the spring should be 180mm to 210mm measured from the loop bearing faces.

Tools Required: 2x 10mm Spanners, 1x Slow Release Ratchet Straps. Optional: Forklift/Overhead

Crane, Hammer

Check each foot for any signs of damage. Measure and record the height of each foot. Replace foot

when foot height is under 105mm. Note: Securing bolts to be wrench tight.

Tools Required: 2x 13mm Socket with 6” extensions, Inspection Stands. Optional: Forklift/Overhead

Crane

Check for any signs of damage or excessive corrosion. Inspect welds for signs of deformation of

cracking. Note: Replace any parts deformed greater than 10mm or any signs of cracking.

Tools Required: 2x 17mm Spanners, Inspection Stands. Optional: Forklift/Overhead Crane

Inspect each panel for any signs of damage. Note: Replace the panel if the foam core has been

exposed, or if the panel is no longer secure when fitted.

Tools Required: 1x 6 mm Allen Key. Optional: Overhead Crane, Ladder/Platform

Check both sections of floor grating for any damage. Ensure that the bolts securing the grating are

secure. Inspect the edging strips for any damage. Note: Replace damaged floor grating, in order to do

so the passenger restraints will need to be removed.

Tools Required: 1x 6 mm Allen Key, Inspection Stands. Optional: Overhead Crane

Loading...

Loading...