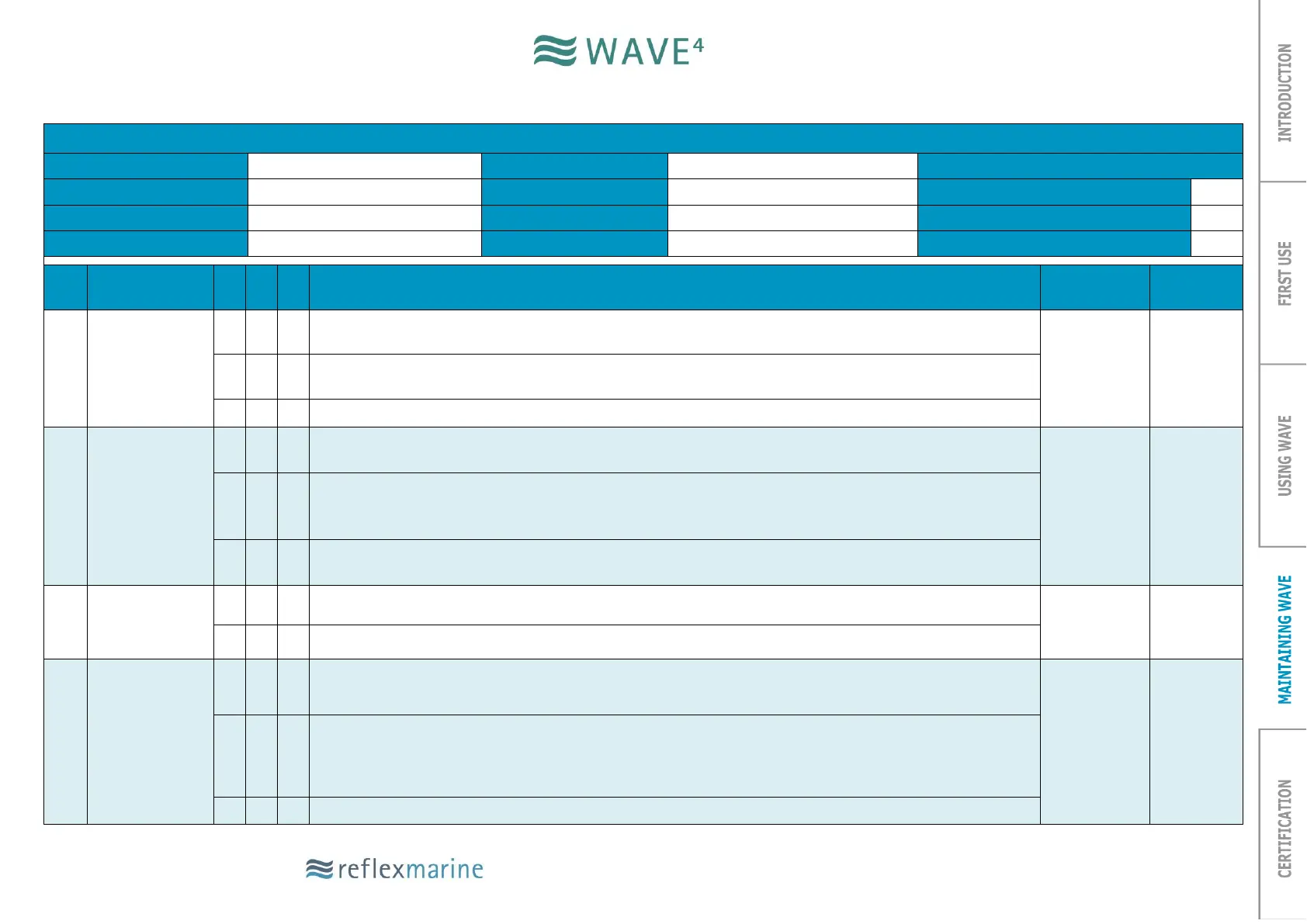

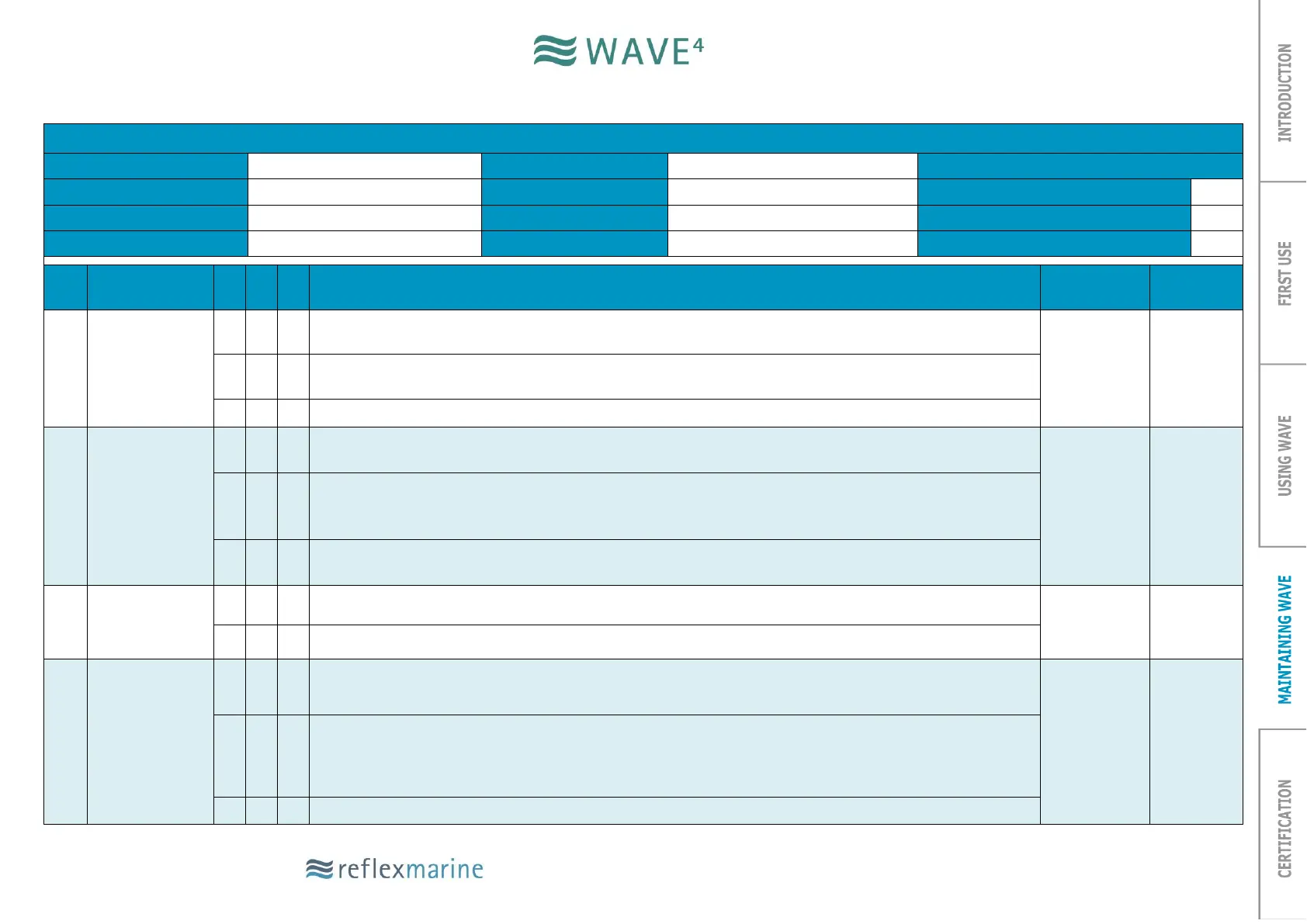

4.10 WAVE Inspection Checklist Form

WAVE Inspection checklist form (Page 1/3)

Post Load Test Inspection (P)

Lifting

Assembly

(Critical Part)

(Consumable)

Check correctly attached. Check terminations and hardware. Remove cover and check each wire rope

leg for signs of damage. Replace cover. Record Serial Number in comments.

Replace Lifting Assembly according to the WAVE usage level. Irrespective of apparent condition Lifting

Assembly should be replaced at least every 12 months. Record new Serial Number in comments.

Tools Required: 1x 36mm spanner, 1x 32mm spanner, 1x pliers. Optional: tray, hammer.

Lifting

Assembly

Safety Bolts

(Critical Part)

(Consumable)

Check for damage. Check split pins and tamper proof seals are fitted, and nuts are securely fastened.

Replace items where required. Record Colour Code against certificates in comments.

Remove and inspect thread and nuts for damage. Depending on the usage level, you might need to

replace these bolts. If bolts are being re-used, clean threads and lubricate with copper grease. Replace

split pins, nuts and tamper proof seals. Note: Hand tighten.

Tools Required: 1x 36mm spanner, 1x 32mm spanner, 1x Pliers. Optional: tray, copper grease,

hammer.

Lift Plates

(Critical Part)

Check securely fastened and for any signs of damage. Record Serial Number in comments.

Remove each plate from the unit and check condition. Pay particular attention to cross holes.

Lift Plate

Safety Bolts

(Critical Part)

(Consumable)

Check for damage. Check split pins and tamper proof seals are fitted, and nuts are securely fastened.

Replace items where required. Record Colour Code against certificates in comments.

Remove and inspect thread and nuts for damage. Depending on the usage level, you might need to

replace these bolts. If bolts are being re-used, clean threads and lubricate with copper grease. Replace

split pins, nuts and tamper proof seals. Note: Tighten to 60Nm.

Tools Required: 2x 19mm Spanner, 1x Pliers, 1x Torque Wrench, Optional: Parts Tray, Hammer

Loading...

Loading...