86

7. Programming

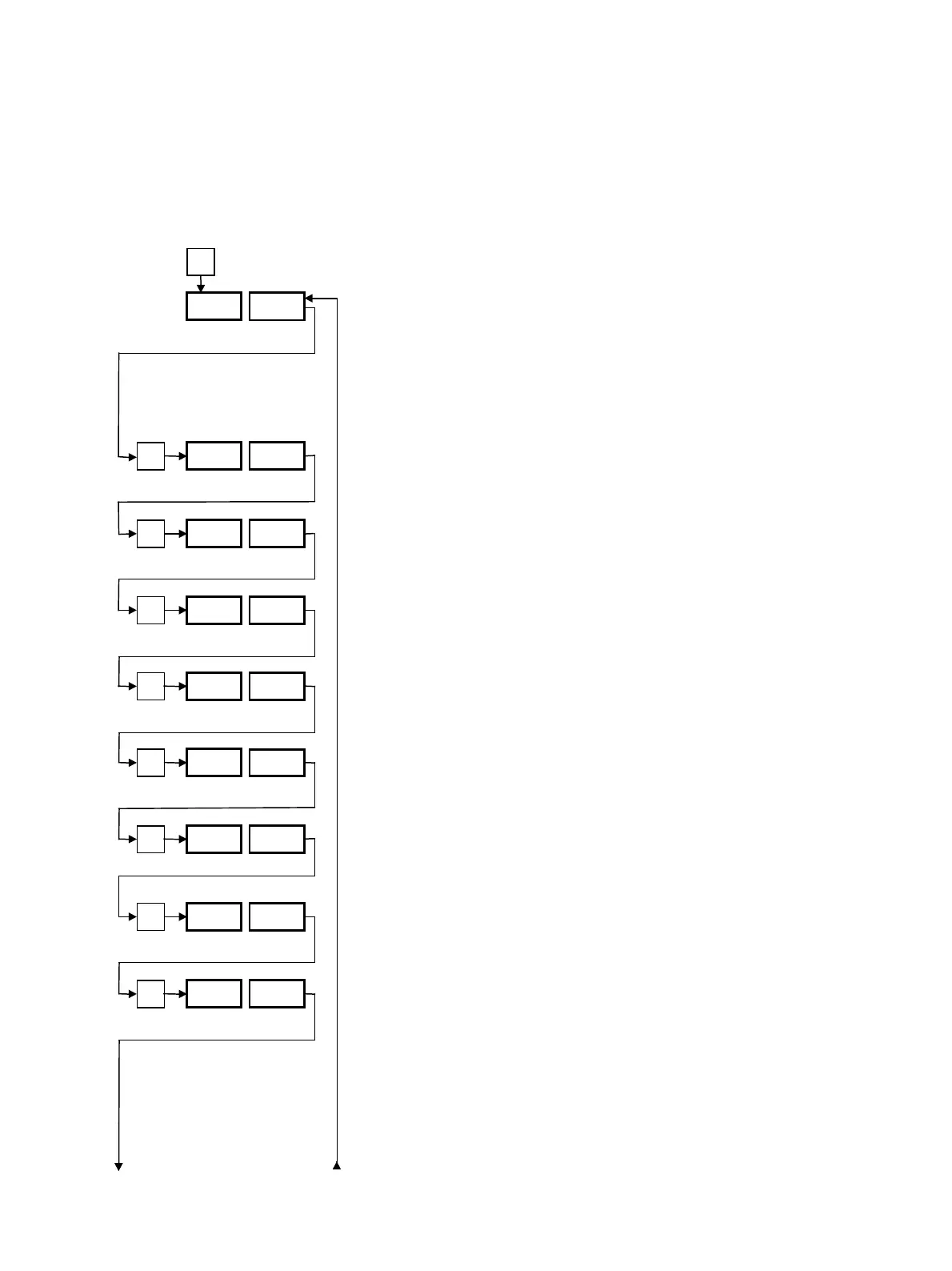

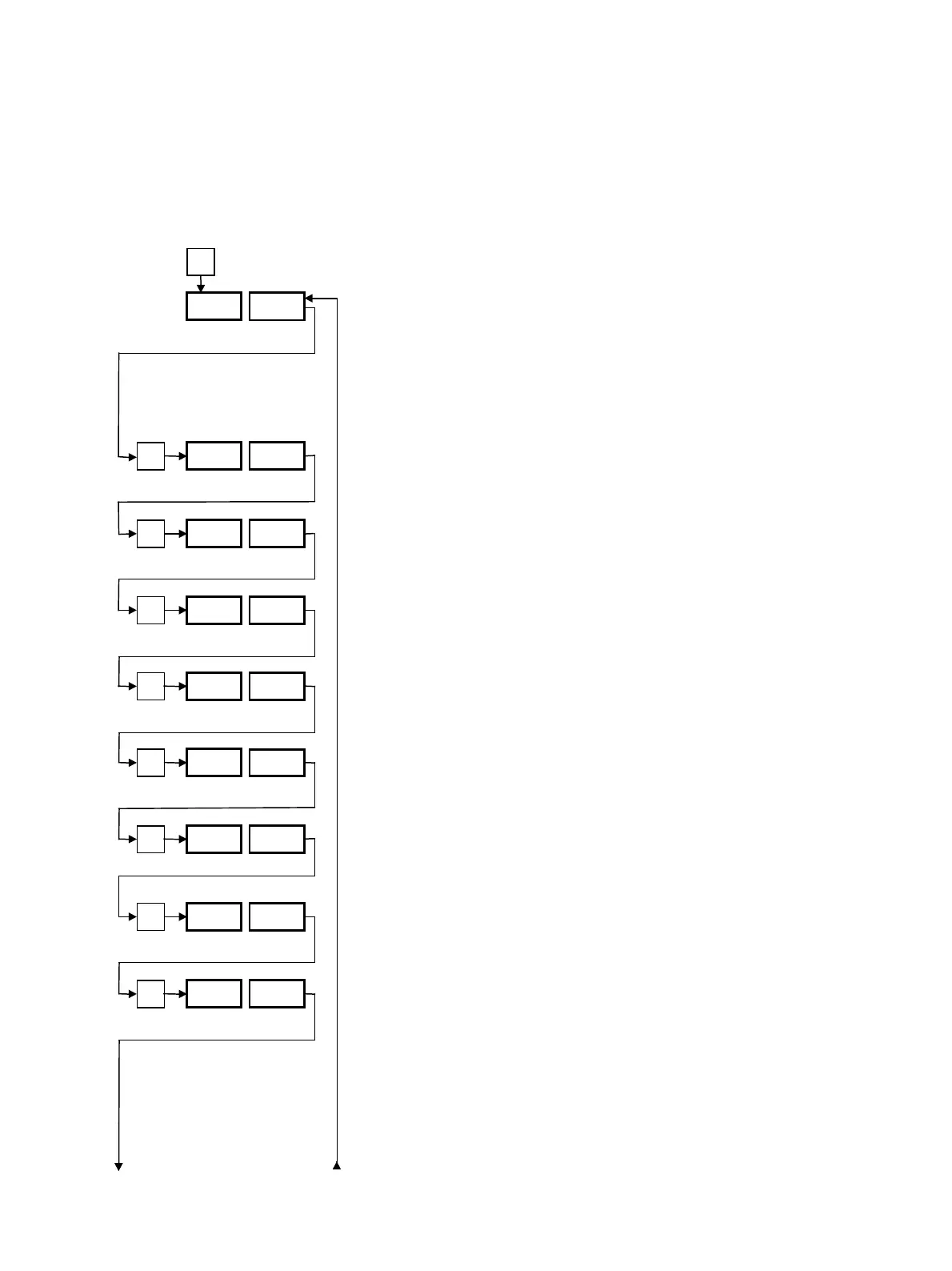

Programming is done via the “∆” and “∇” keys to raise or

lower the alignment values or to reach the desired align-

ment in the appropriate level (e.g. “Ltr” or “GAL”, see Sec-

tion 7.2, fig. “VAL”).

7.1 Operator Level “SEt SEL”

For programming the temperature-probe limit values (SEt

SEnsor Limits, see Section 11.1, Fig. 2) and the parameter

for measuring flow rate (if present).

This level is reached by pressing the “P” key for 3 s.

To go back one step, press the “P” key for a maximum of

2 s.

To return to the operating level with display of set and actual

values from any desired level, press the “P” key for 3 s.

Upper limit value of fluid temperature (°C) with reference to

the set value. Alarm when exceeded. 0 = function off.

Lower limit value of fluid temperature (°C) with reference to

the set value. Alarm when value falls below.

0 = function off.

Upper limit value of consumer temperature (°C) with refer-

ence to the set value. Alarm when exceeded.

0 = function off.

Lower limit value of consumer temperature (°C) with refer-

ence to the set value. Alarm when value falls below.

0 = function off.

If measurement of flow rate is available:

minimum flow in l/min. Alarm when value falls below.

Second set value “SP2” (max. S¯

¯, see Section 7.2).

With cascade control, the fluid temperature can be limited

(max. S¯

¯, see Section 7.2) via the external sensor Sn2.

0 = function off.

With cascade control, the fluid temperature can be limited

via the external sensor Sn2.

0 = function off.

P

3 s

SEt SEL

P

S1

–

0

0 to 99

P

S1

–

0

0 to 99

P

S2

–

0

0 to 99

P

S2

–

0

0 to 99

P

FLC

2

2 to 50

P

SP2 0

0 to S

–

–

P

Ll

–

0

0 to S

–

–

P

Ll

–

0

0 to S

–

–

Loading...

Loading...