Page 10

Adjust and check condition of the fan belt

The fan belt should be sufficiently tight to drive the alternator and

water pump without loading the bearings unduly. The adjustment is

correct when the belt can be moved laterally 13 mm (½ in) at the mid

point between the alternator and water pump pulleys. (figure 9) If

adjustment is necessary proceed as follows:

1. Slacken the alternator front mounting bolt.

2. Slacken the adjustment locking screw at the front of the

alternator allowing it to be moved on the slotted strap.

3. Pivot the alternator away from the engine until the correct

slack is achieved. Maintain the alternator in this position and tighten

the locking screw and front mounting bolt. Re-check the adjustment.

Note: The front lower mounting must be slackened completely before

making any adjustment as any strain on the lower fixings could distort

or damage the mountings.

Regularly examine the fan belt for wear and renew if necessary.

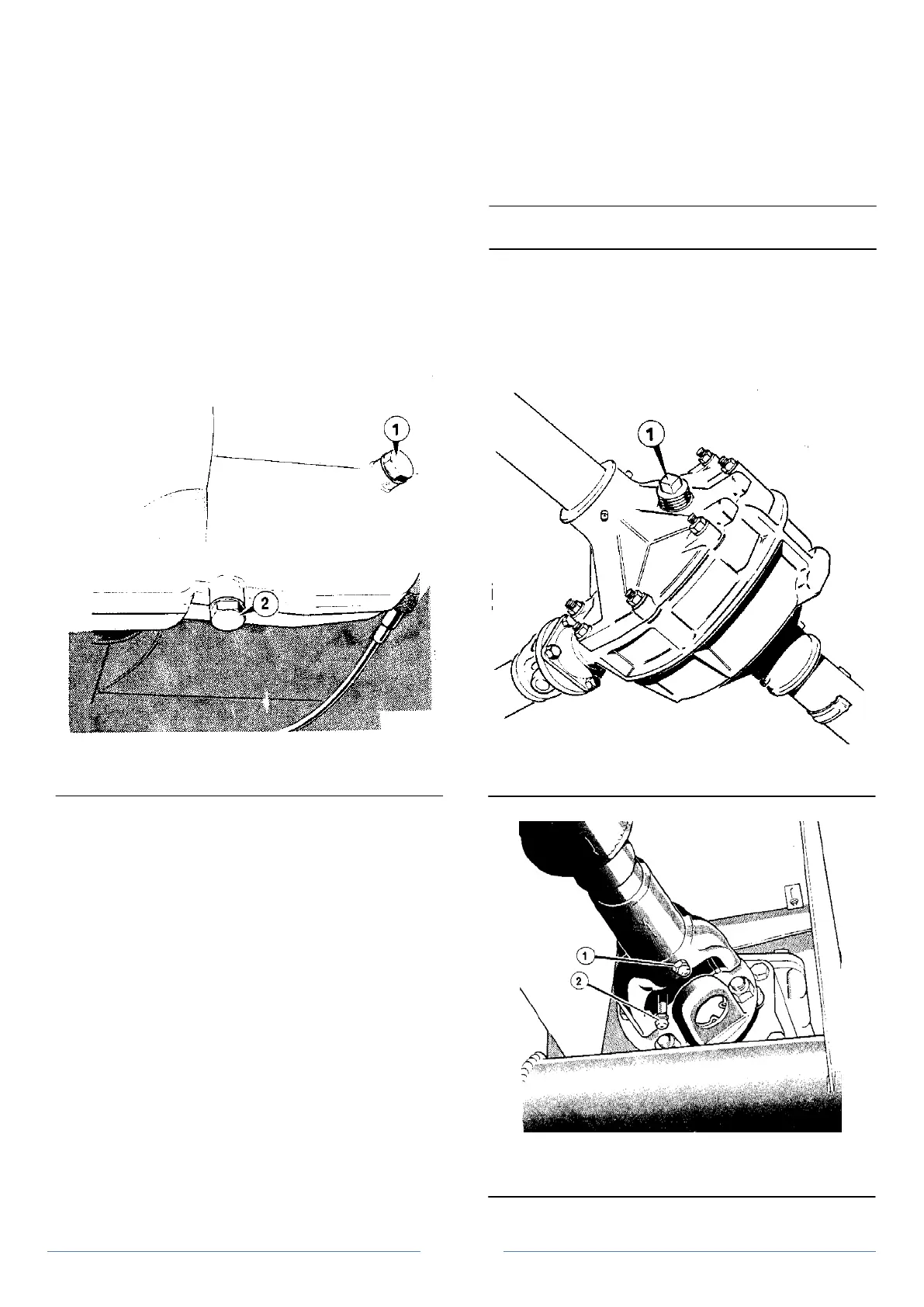

Figure 10 Gearbox oil level and drain plugs

1. Filler/level plugs.

2. Drain plug.

Check security of starter and alternator fixing bolts

Starter Motor

Using a torque wrench set to 4.15 to 4.84kg/m (30 to 35

lb/ft) check tightness of attachment nuts and bolts.

Alternator

1. Check tightness of front mounting bolt - 2.1 to 2,7 kg/m (15

to 20 lb/ft).

2. Check alternator to strap locking screw - 1.1 to 1,3 kg/m (8

to 18 lb/ft).

Check security of engine mountings

The engine and gearbox assembly is secured to the frame at three

points.

1. Check tightness of front right and left hand attachment nuts

- 2.76 to 3.46 kg/m (20 to 25 lb/ft).

2. Check tightness of gearbox rear attachment nuts - 2.07 to

2.49 kg/m (15 to 18 lb/ft).

Check/adjust carburettor settings

Start the engine and warm to normal running temperature. Push the

choke control fully home.

1. Ensure the fast idling screw is clear of the choke cam.

2. Adjust idling screw to achieve an idling speed of

approximately 800 to 850 rpm. Should these adjustments fail to

achieve satisfactory results refer to Section P.

Lubricate accelerator linkage

Using an oil can, lubricate the accelerator linkages on the carburettor.

Wipe away surplus oil (figure 5)

Routine maintenance - under body

Check and top-up gearbox oil

1. Place the vehicle on ramp or over pit.

2. Remove gearbox level plug and observe oil level correct

when in line with the bottom of the level hole threads (figure 10).

3. If necessary top up via the level hole using a pump type oil

can with a flexible nozzle charged with the recommended oil until the

level is correct.

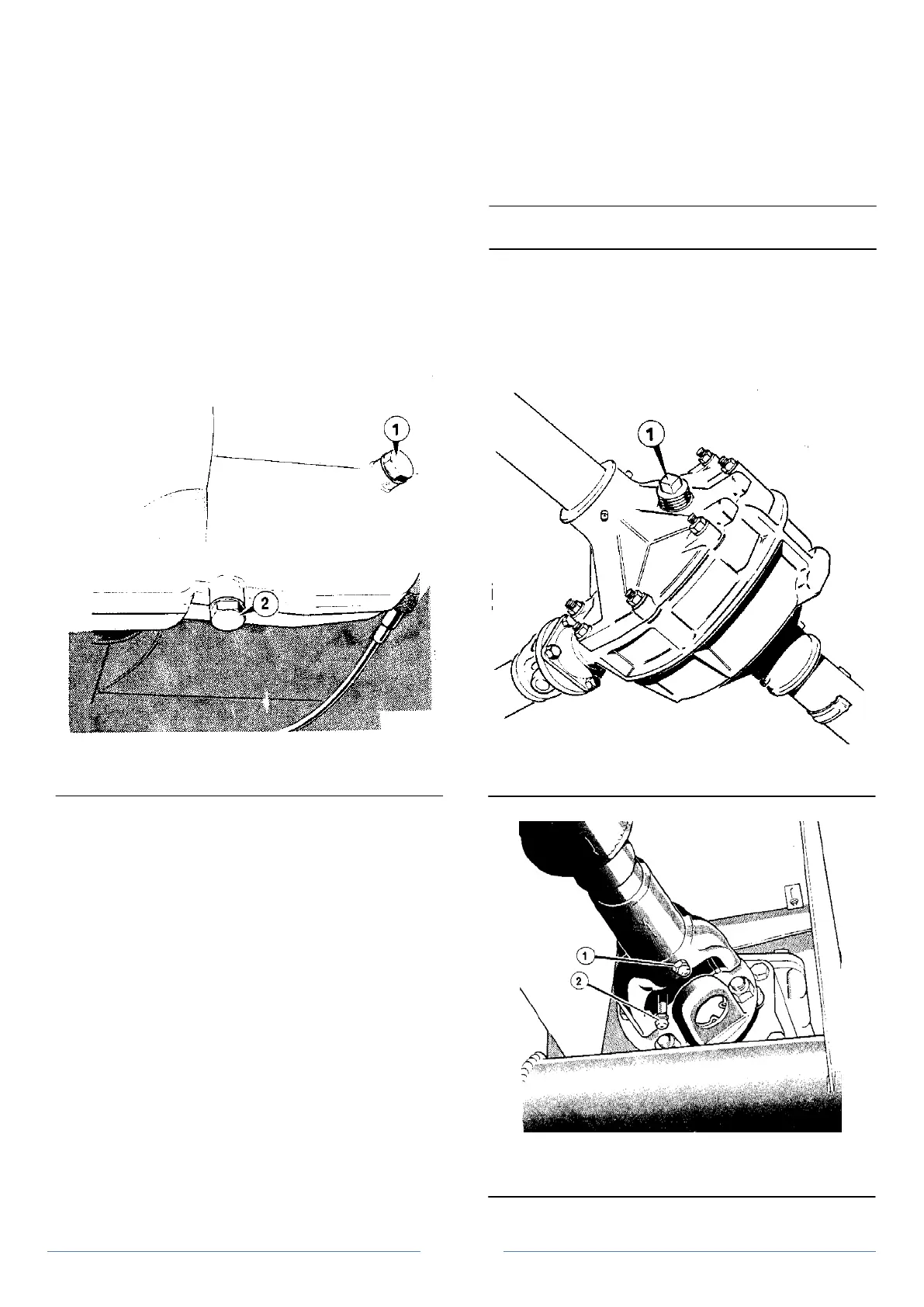

Figure 11 Rear axle oil filler/level plug

1. Filler/level plug.

Figure 12 Driveshaft grease nipples

1. Sliding spline grease nipple.

2. Universal joint grease nipple.

Loading...

Loading...