The unit must only be located internally. It is not suitable

for installation in hazardous locations and should not be

sited near to any electromagnetic field. The controller must

additionally be equipped with an all-polar gap of at least 3 mm

or with a gap according to the valid installaton regulations,

e.g. LS-switches or fuses. Please pay attention to a separate

laying of the cable lines and installation of ac power supply.

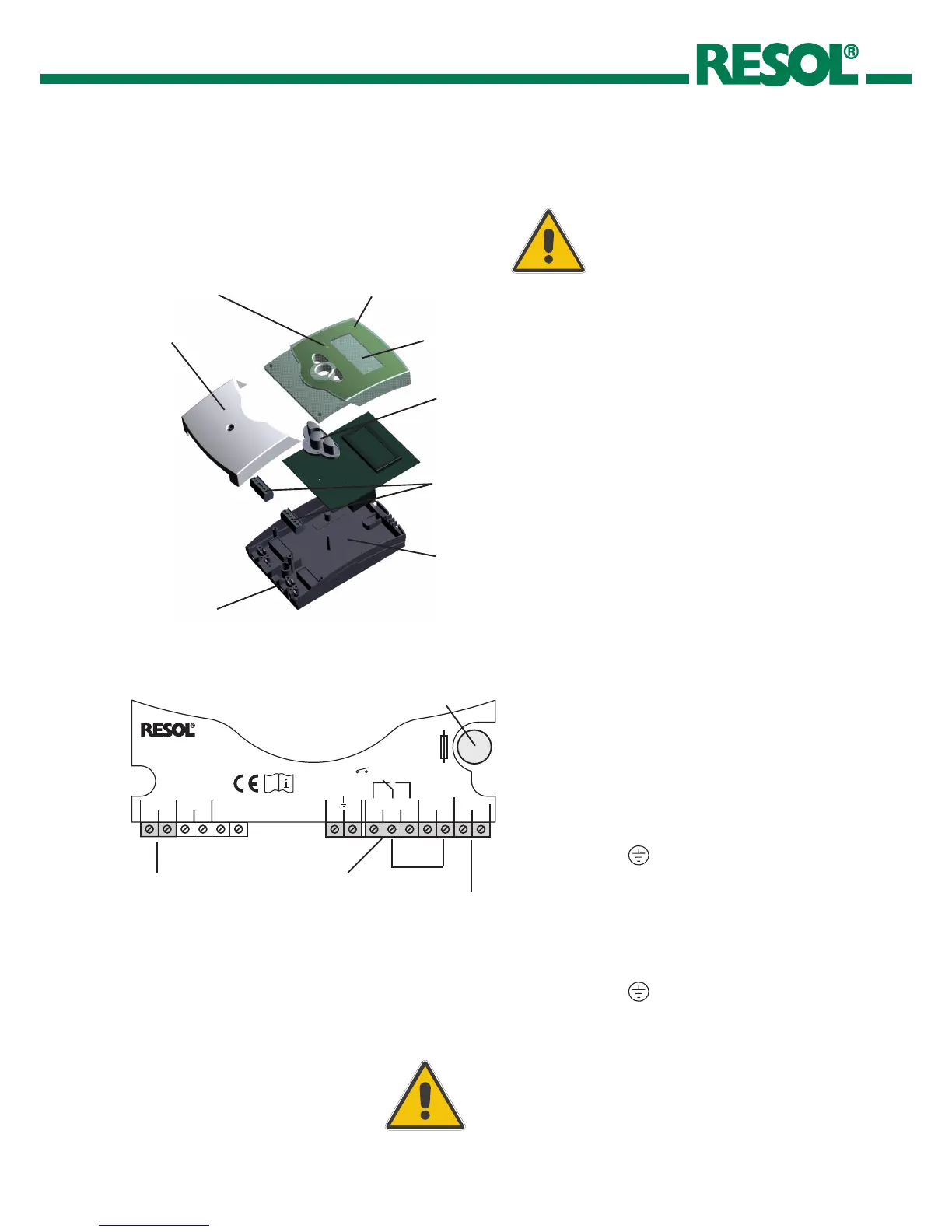

1. Unscrew the cross-recessed screw of the cover and

remove it from the housing.

2. Mark the upper fastening point on the underground and

premount the enclosed dowel and screw.

3. Hang up the housing at the upper fastening point and mark

the lower fastening point on the underground (hole pitch

130 mm), afterwards put the lower dowel.

4. Fasten the housing at the underground.

Warning!

Switch-off power supply before

opening the housing.

housing

key field

base

clamps

cover

cable conduits with strain relief

operation control lamp

combined LCD

2.1 Mounting

2. Installation

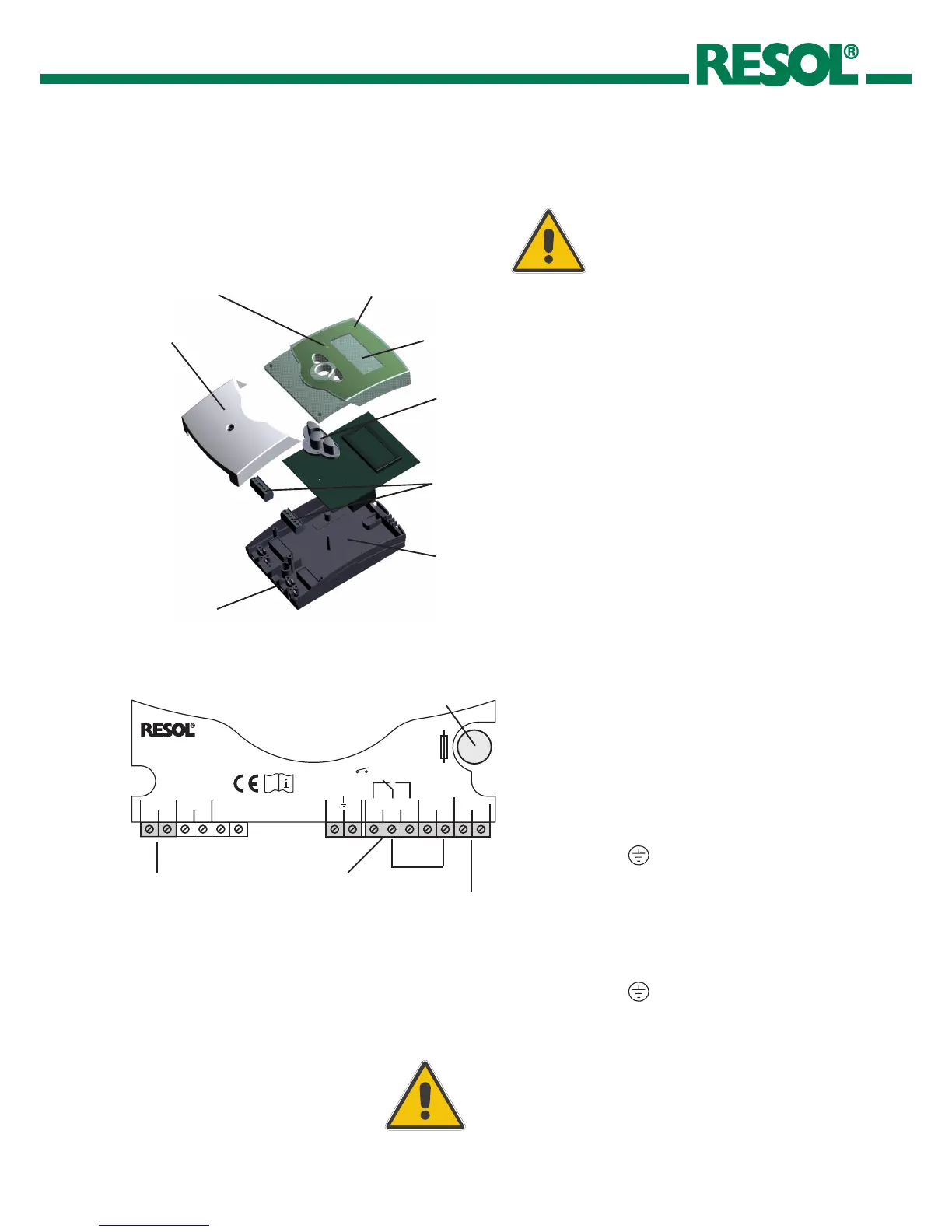

2.2 Electrical connection

The power supply to the controller must only be made by

an external power supply switch (last step of installation!)

and the line voltage must be 220 ... 240 Volt (50...60 Hz).

Flexible lines are to be fixed at the housing by enclosed

strain relief supports and screws.

The controller is equipped with 1 standard relays, to

which the consumers can be connected:

14 = normally closed contact R

15 = middle contact M

16 = normally open contact A

13 = ground clamp

The temperature sensors (S1) will be connected to the

following terminals independently of the polarity:

1 / 2 = sensor for heat source / heat sink

The power supply is effected to the clamps::

19 = neutral conductor N

20 = conductor L

12 = ground clamp

net clamps

sensor clamps

consumer clamps

Notice:

The middle contact M (15) and the conductor L (18) are

bridged from factory.

After removal of the bridge the changeover contact (RMA)

becomes a potential-free relais.

bond bridge

Loading...

Loading...