Form I-ADF, Page 14

FIGURE 11A -

Factory-installed

Evaporative Cooling

Module Option on

Models ADF/ADFH 300

and 500

Evaporative cooling provides excellent comfort cooling at low initial equipment and

installation costs and low operating and maintenance costs. Direct evaporative

cooling works on the principles that water in direct contact with a moving airstream

will eventually evaporate if the droplets have long enough exposure and that the

evaporation will lower the air temperature.

The optional evaporative cooling module is equipped with high efciency pad media

of either 12" rigid cellulose or 12" rigid glass ber. 12" media provides 90% efciency.

Efciency value is stated at maximum allowable CFM (without the optional moisture

elimination pad) and with an inlet dry bulb temperature of 95

°

F and an inlet wet bulb

temperature of 65

°

F. Evaporative cooling efciency is a function of inlet temperature

(wet and dry bulbs) and of face velocity through the pads. The stated cooling efciency

will rise with the decrease of velocity and increase of inlet temperature. Moisture

elimination pads (Option ASA1) may be used on all units but are required on high CFM

units (velocity above 6000 FPM) as listed in the table below.

Model/Size

Moisture Elimination Pad Required Size

on the Evaporative Cooling Module at

ADF/ADFH 300 3200 CFM

ADF/ADFH 500 4500 CFM

ADF/ADFH 700 11200 CFM

ADF/ADFH 1200 11200 CFM

Models ADF/ADFH 300/500 - When ordered with an evaporative cooling option, Sizes

300 and 500 are shipped as a factory-assembled makeup air heating/evaporative

cooling system. The module is factory installed including all wiring connections (See

FIGURE 11A). Follow the instructions in this section for water connections and water

ow adjustments.

6.2.4 Evaporative

Cooling Module -

Options AS4 and AS8

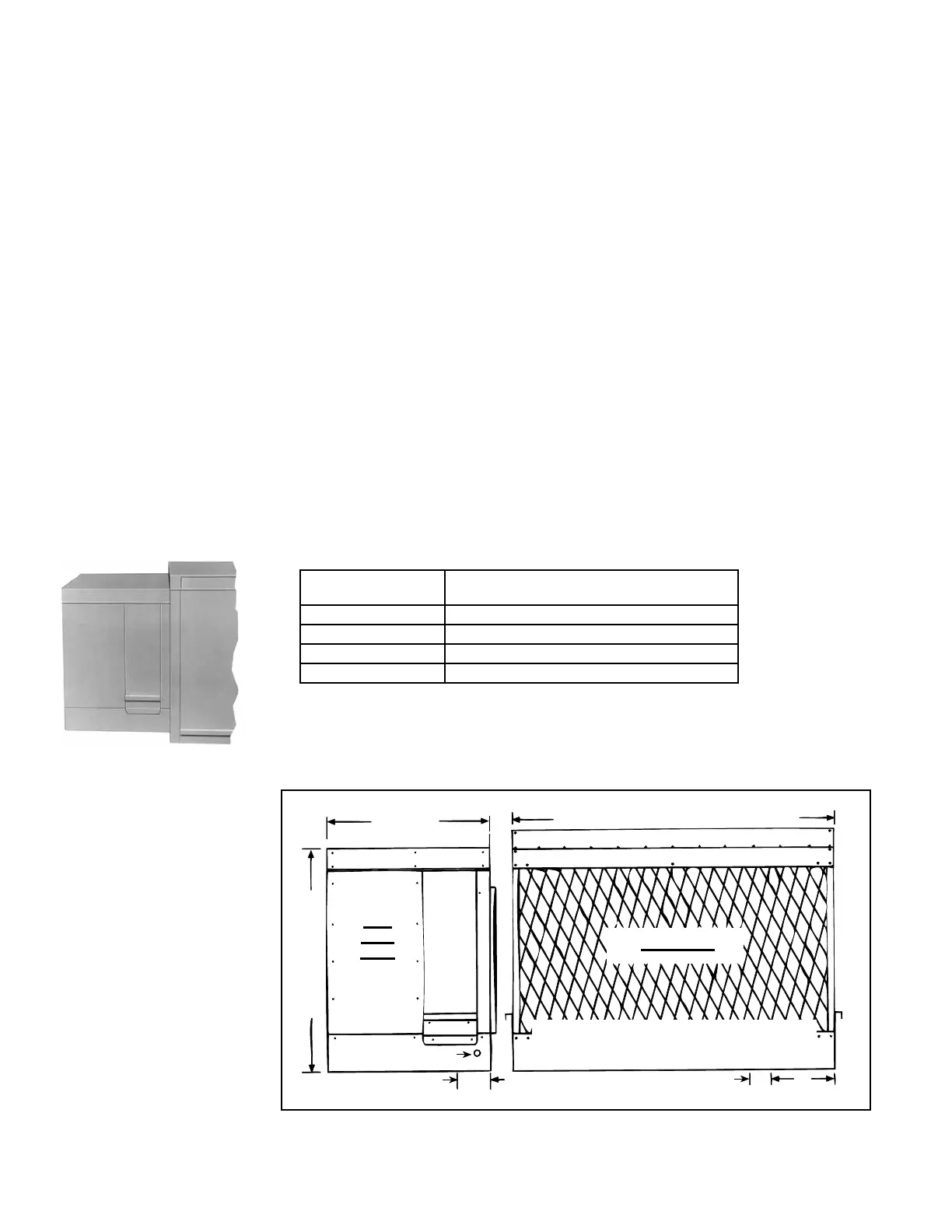

FIGURE 11B -

Dimensions of optional

evaporative cooling

module factory-installed

on Sizes 300 and 500

3. Re-insert all of the screws across the top of the cabinet.

4. The lter cabinet should be resting on the factory-installed support angle across

the bottom of the cabinet. If the cabinet does not rest tightly against the support

angle, follow these instructions to adjust the position of the support angle:

a) Slightly loosen (do not remove) the support angle screws.

b) Slide the support angle up (holes are slotted) so that it is against the bottom

panel.

c) Tighten the screws.

5. If equipped with an optional dirty lter switch, locate the coil of clear tubing attached

to the dirty lter switch in the electrical compartment. Extend the tubing to the air

entering side of the lter rack. Attach the end of the tubing being careful that it is not

compressed or kinked. (See Paragraph 7.3 for switch details.)

Models ADF/ADFH 700/1200 - The evaporative cooling module for Sizes 700 and

1200 is assembled at the factory and shipped separately for eld-connection to the

makeup air system cabinet. The shipped separate option includes the cooling module,

6.0 Mechanical

(cont'd)

6.2 Unit Inlet Air

(cont'd)

6.2.3 Indoor Filter

Cabinet (cont'd)

Loading...

Loading...