23

23

G

B

POINT B - SETTINGS

DIP 1 (ON) MOTOR ROTATION DIRECTION CHECK (See

Point C)

DIP 2 (ON) PROGRAMMING (See Point D)

DIP 1-2 STORAGE/DELETION OF RADIO CODES FOR

COMPLETE OPENING (DIP 1 ON followed by DIP 2 ON)

(POINT G) ONLY FOR CRX MODELS

DIP 1-3 STORAGE/DELETION OF RADIO CODES FOR PEDESTRIAN

OPENING (DIP 1 ON followed by DIP 3 ON) (POINT H) ONLY FOR

CRX MODELS

DIP 2-1 PROGRAMMING OF THE PEDESTRIAN OPENING (See Point F)

DIP 3 ON - Automatic Closing ENABLED

OFF - Automatic Closing DISABLED

DIP 4 ON - Photocells active only in closing

OFF - Photocells always active

DIP 5 ON - blinker pre-flashing

OFF - blinker normal-flashing

DIP 6 OFF - STEP BY STEP

Single pulse contact (K BUTT)

Pedestrian button (PED BUTT)

Radio Receiver command

ON - AUTOMATIC

Single pulse contact (K BUTT)

Pedestrian button (PED BUTT)

Radio Receiver command

DIP 7 ON - low speed in approaching ENABLED

OFF - low speed in approaching DISABLED

DIP 8 ON - electric lock command ENABLED

OFF - electric lock command DISABLED

DIP 9 ON - Hammering on complete close position to ease Manual Release

- Hammering before opening to ease electric lock unlocking

OFF - no impulse

DIP 10 ON - Extra thrust when reached closing position to make sure that the

mechanical bolt is fixed into the ground

OFF no impulse

DIP 11 ON - black out function ENABLED (See chart 2)

OFF - black out function DISABLED

DIP 12 ON - close command after the transit through the photocell ENABLED

OFF - close command after the transit through the photocell DISABLED

DIP 13 ON - safety strip self-test ENABLED

OFF - safety strip self-test DISABLED

DIP 14 to select type of motor (see chart 1)

DIP 15 to select type of motor (see chart 1)

DIP 16 to select type of motor (see chart 1)

JP 17 OPEN JUMPER 1 motor (M1) - 1 leaf

CLOSE JUMPER 2 motors (M1 and M2) - 2 leaves

JP1 => Pay attention that the jumper is inserted!

JP2 => Pay attention that the jumper is inserted!

JP3 => Pay attention that the jumper is inserted!

TORQUE TR1 Electronic regulator for motor torque

Adjustment of motor torque is carried out using the TORQUE Trimmer which varies

the output voltage to the head/s of the motor/s (turn clockwise to increase torque).

This torque control is activated after 2 seconds form any manoeuvre begging,

whereas the motor is turned on at full power to guarantee the starting at the

manoeuvre begging.

PAY ATTENTION: IF THE TORQUE TRIMMER SETTING IS CHANGED, IT IS

PREFERABLE TO REPEAT THE TIME PROGRAMMING.

LOW SPEED TR2 Electronic regulator for low speed on approach

Adjustment of low speed is carried out using the LOW SPEED Trimmer which

varies the output voltage to the head/s of the motor/s (turn clockwise to increase

speed). Adjustment is carried out to establish the correct speed at the completion

of opening and closing, depending on the structure of the gate, or if there is any

light friction that could compromise the correct working of the system. The low

speed is activated (DIP7 OFF) when the gate leaf is 0.50-0.60 meters away from

the complete close or open position.

ATTENTION: WHEN USING HYDRAULIC OPERATORS

When using the hydraulic operators the deceleration phase may not operate

correctly; in that case it is advisable to disable the feature of the deceleration

by putting DIP 7 in the OFF mode.

LED WARNING

DL1 - programming activated (red)

DL2 - radio code programming (green) (only for CRX)

DL3 - gate opening M2 (green)

DL4 - gate closing M2 (red)

DL5 - gate opening M1 (green)

DL6 - gate closing M1 (red)

DL7 - photocell contact (NC) (red)

DL8 - safety strip contact (NC) (red)

FUSES

F1 T315mA Accessories protection fuse

F2 5A Motor protection fuse

POINT C - MOTOR ROTATION DIRECTION CHECK

1 - Unlock the operators with the Manual Release - swing open the leaves about

halfway and lock again the operators.

2 - Turn DIP1 to ON position The red LED DL1 starts blinking.

3 - Press the PROG button and hold it - When GREEN LEDS DL3 and DL5 are

on, the gate leaves are opening (with a phase shift of 2 seconds). Check the

leaves swinging and the opening mechanical stopper position (movement is

now performed in “man present” mode, open-close-open-etc.).

If any of the leaf closes instead of opening, release PROG button, turn off the

main power and reverse the two phase wires (V1/2 and W1/2) of the relevant

motor/s.

4 - Press the PROG button and hold it to CLOSE completely the gate. When RED

LEDS DL4 and DL6 are on, the gate leaves are closing (with a phase shift of 4

seconds). Check leaves swinging and the closing mechanical stopper position.

5 - After 3 seconds motor starting and for the next 10 seconds motor working, the

torque controls automatically activated. Set the motor torque by the TORQUE

Trimmer/s which varies the output voltage to the motor/s (turn clockwise to

increase the torque).

6 - After other 10 seconds motor working, the low speed controls automatically

activated (DIP7 ON). Set the motor low speed by the LOW SPEED Trimmer to

select the gate leaf low speed in approaching.

7 - Close completely the gate.

8 - Turn DIP1 to OFF position, LED DL1 turns off.

During Point C procedure, safety devices (photocells and safetystrip) are not

active and the remote control cannot operate.

(#) In Point D, Point E and Point F procedures, all the safety devices (photocells

and safety strip) will be active, so they must be properly installed and connected

to the control board. Any changing of the safety devices input state, will stop the

Point D, Point E or Point F procedure that must be repeated from the beginning.

POINT D - PROGRAMMING FOR 2 MOTORS (#)

1 - The gate must be fully closed.

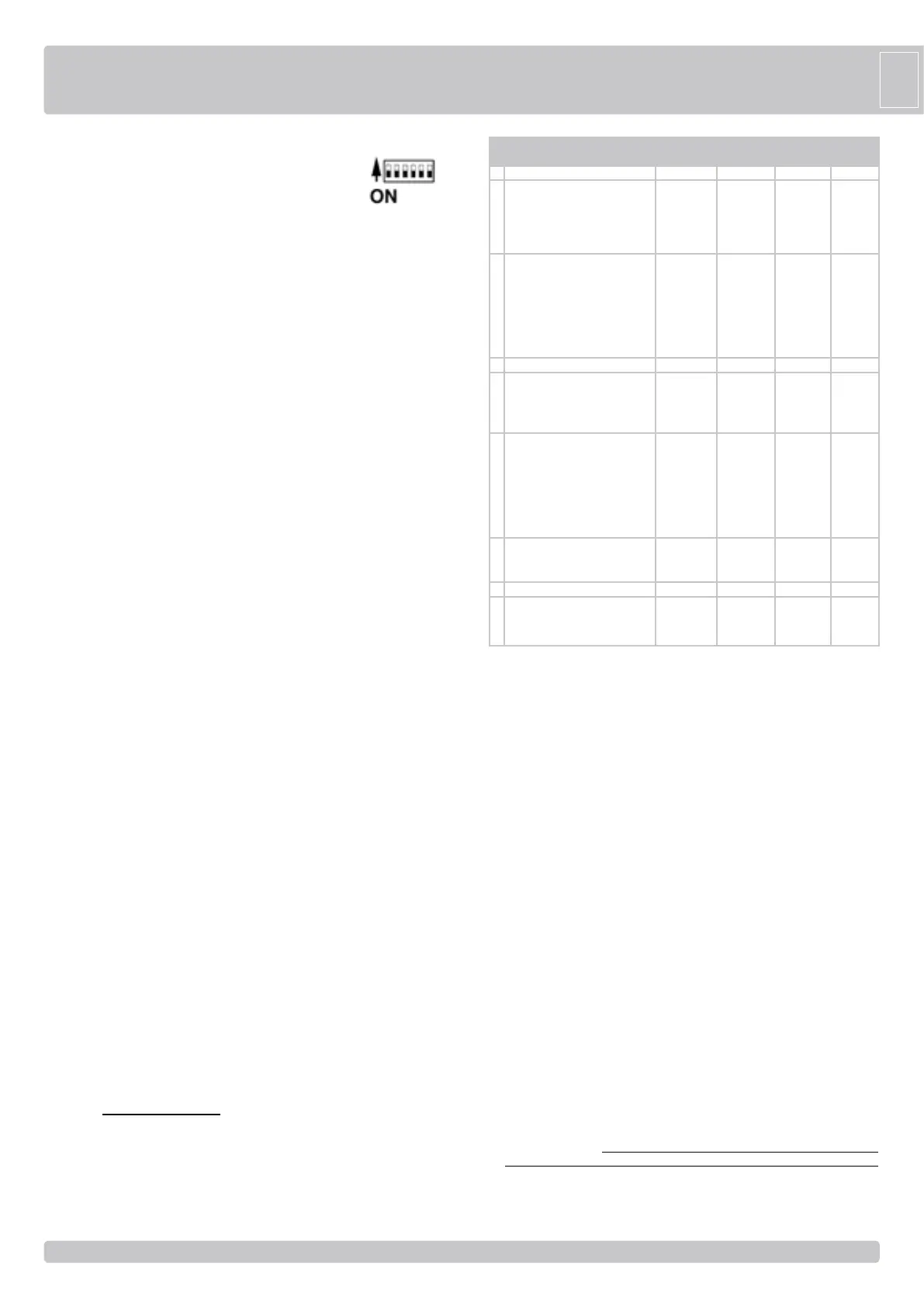

TABLE 1

TYPEOFMOTOR CODE DIP14 DIP15 DIP16

1 KING230/50 AA14001 OFF OFF OFF

KINGL230/50 AA14010

KING220/60 AA14002

KINGL220/60 AA14011

KINGICE230/50 AA14019

2 MAGICIRR.105° AA10960 ON OFF OFF

MAGICIRR.180° AA10965

MAGICREV.105° AA10920

MAGICREV.180° AA10930

DUKE110° AA10975

DUKE180° AA10985

PRATIC AA18001

3 PRINCEREV AA14045 OFF ON OFF

4 IDRODUE27/R AA10843 ON ON OFF

IDRODUE27/1B AA10844

IDRODUE27SUPER/R AA10809

IDRODUE27SUPER/1B AA10804

5 FLUIDRDVI AA10899 OFF OFF ON

FLUIDRSVI AA10901

FLUID2BDVI AA10897

FLUID2BSVI AA10898

IDRO39/R AA10871

IDRO39/1B AA10876

IDRO39/2B AA10881

6 KINGFAST230/50 AA14008 ON OFF ON

KING120/60 AA14003

KINGL120/60 AA14012

7 R50 AA21580 OFF ON ON

8 IDROC27/1B AA10884 ON ON ON

IDROC27/2B AA10882

IDROC27/R AA10883

Loading...

Loading...