Technical information

Maintenance

2

Ridder Drive Systems B.V. T +31 (0)341 416 854 I ridder.com E info@ridder.com

9

Maintenance RRD700 rack drives

Inspection and maintenance work is only permitted to approved personnel.

Installation RRD700

After installation, RRD700 rack-drive, plastic bearing (opposite system) and rack (teeth, sides, bottom)

have to be lubricated! Refer to "Lubricate RRD700".

Maintenance RRD700

Every 6 months inspection of system and rack drives on technical state (wear and tear, shaft

connections, fasteners and such) and proper functioning. With this the RRD700 rack-drive, plastic

bearing (opposite system) and rack (teeth, sides, bottom) have to be lubricated. Refer to "Lubricate

RRD700".

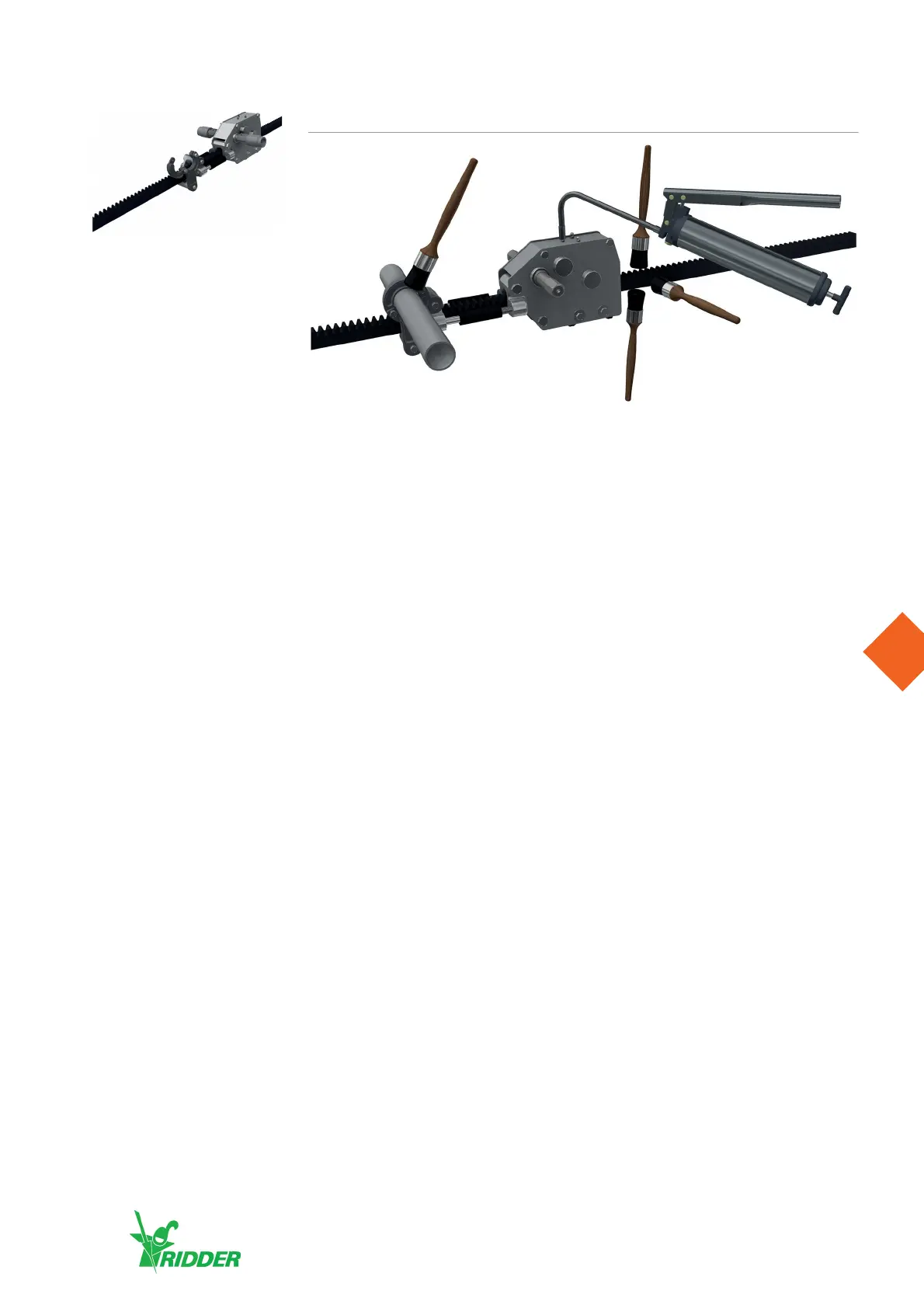

Lubricate RRD700

● Lubricate pinion-house unit with grease gun (approximately 5 strokes per grease nipple).

● Lubricate rack (all around) with brush (teeth, sides, bottom).

● Lubricate plastic bearing (opposite system) all around (fully: between surfaces tube/bearing) with

brush.

Lubricant RRD700

Grease: CASTROL OPTILEB-GR 823-2 (item number: 182029)

Loading...

Loading...