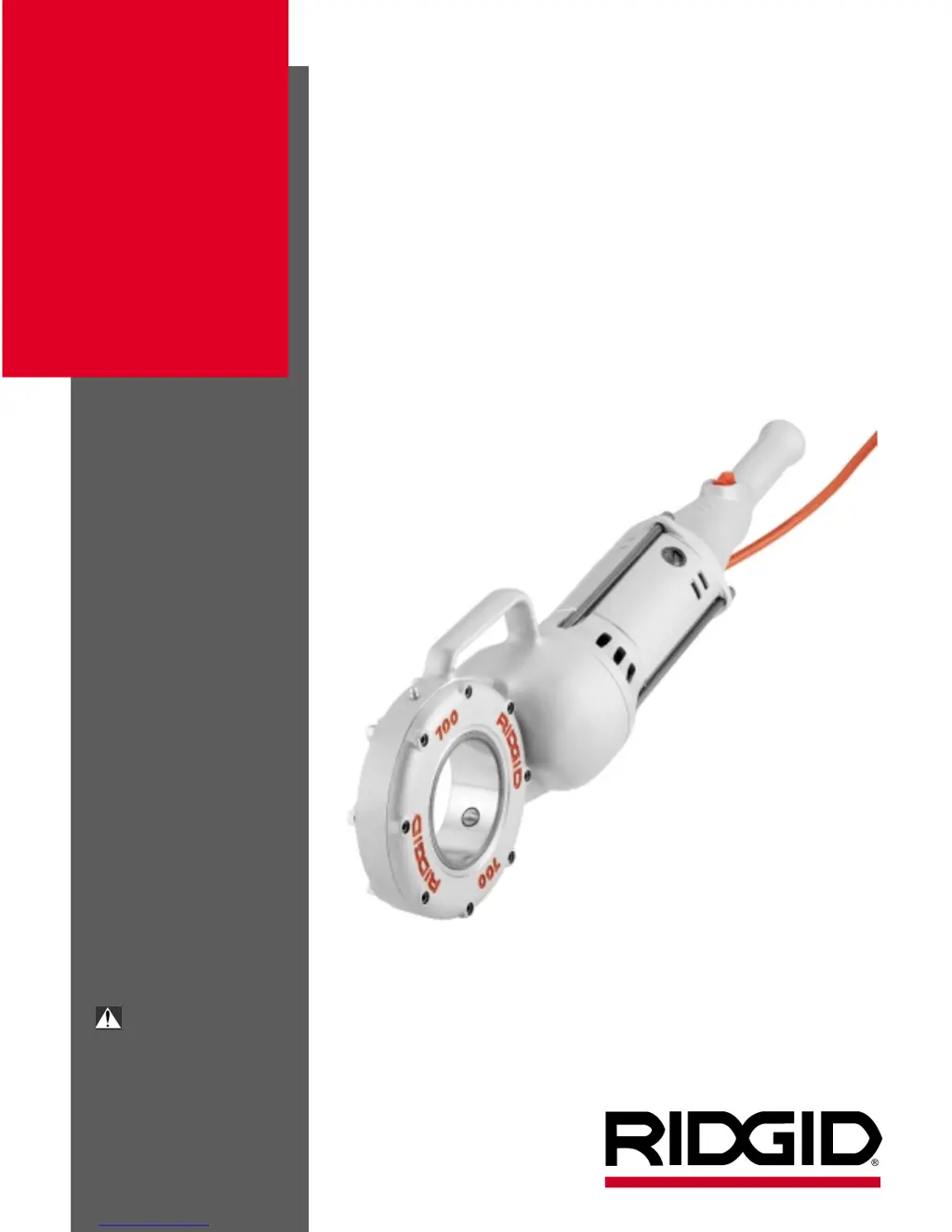

How to troubleshoot a RIDGID 700 Power Tool that won't start?

- QqcooperJul 26, 2025

If the RIDGID Power Tool motor doesn't start, first ensure it's plugged into a power source. If it is, check the fuse and replace it if blown. Also, inspect the brushes to ensure they are making contact with the armature; replace them if they're worn.