Used in Conjunction with the Following Power

Drives and Threading Machines

• 300 Power Drive (38 and 57 RPM)

• 535 Threading Machine (38 and 54 RPM)

• 1822 Threading Machine

• 1224 Threading Machine

• 535 Automatic Threading Machine

Standard Equipment

918 Roll Groover Only

• 918 Groover with 2″ – 6″ drive shaft and groove set

•8″ – 12″ Drive shaft and groove set

• Carrying case for drive shaft and groove set

•

1

/

8

″ T-Handle hex wrench (groove roll change out)

• Wrench (drive shaft changeout)

918 Roll Groover Models

Roll Groover Assembly

Instructions

WARNING

The 918 Roll Groover should only be used with the

following power drives and threading machines.

• 300 Power Drive (38 and 57 RPM)

• 535 Threading Machine (38 and 54 RPM)

• 1822 Threading Machine

• 1224 Threading Machine

• 535 Automatic Threading Machine

Use only power drives and threading machines

that operate at 58 RPM or less. Higher speed ma-

chines increase risk of injury.

To prevent serious injury, proper assembly of the

Roll Groover is required. The following procedures

should be followed:

918 Roll Groover

Ridge Tool Company4

Description, Specifications and

Standard Equipment

Description

The RIDGID 918 Heavy Duty Roll Groover forms rolled

grooves in steel, stainless steel, aluminum, PVC pipe and

copper tubing. The grooves are formed by the hydraulic

feeding of a grooving roll into the pipe which is sup-

ported by a drive roll.

The 918 Roll Groover includes two (2) groove and drive

shaft sets that can groove the following pipe:

•2″ – 6″ Schedule 10 and 40

•8″ – 12″ Schedule 10 and 8″ Schedule 40

With additional roll sets, the groover can also be adapted

to groove the following:

•2″ – 6″ copper tubing (Types K, L, M, DWV);

•1″ Schedule 10 and 40;

•1

1

/

4

″ – 1

1

/

2

″ Schedule 10 and 40.

The 918 Heavy Duty Roll Groover is specifically designed

for use with the RIDGID 300 Power Drive, as well as

RIDGID 535, 535A, 1822, and 1224 Threading Machines.

Different mounting kits are required for each power source.

When properly used, the Model 918 makes

grooves that are dimensionally within the specifications of

AWWA C606-87. Selection of appropriate materials and

joining methods is the responsibility of the system de-

signer and/or installer. Before any installation is attempted,

careful evaluation of the specific service environment, in-

cluding chemical environment and service temperature,

should be completed.

Specifications

Roll Grooving Capacity

(See Table II for wall thickness)

•1″ – 12″ Schedule 10

•1″ – 8″ Schedule 40

•2″ – 6″ Copper types K, L, M, DWV

•2″ – 8″ Schedule 40 PVC

Do not use to groove 8″ schedule 40 steel

pipe harder than 150 BHN. Doing so may result in im-

properly formed grooves that do not meet required

specifications.

Depth Adjustment ..........Indexed adjustment knob

Actuation ........................Hydraulic hand pump

CAUTION

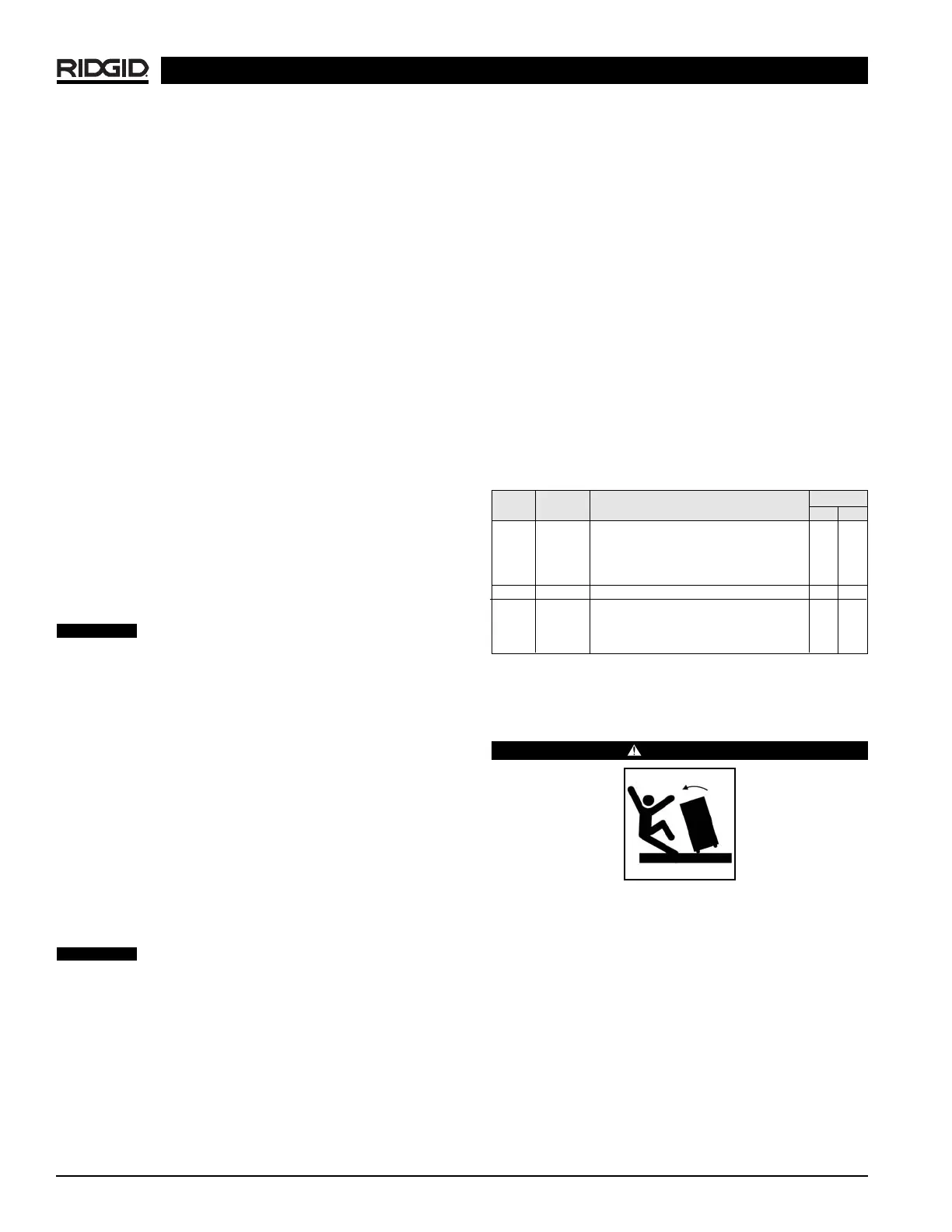

Catalog Model Weight

No. No. Description lb. kg.

48297 918-1 918 Roll Groover w/300 Power Drive Mount Kit 81 36,7

48377 918-2 918 Roll Groover w/1822 Carriage Mount Kit 81 36,7

48382 918-4 918 Roll Groover w/1224 Carriage Mount Kit 81 36,7

48387 918-5 918 Roll Groover w/535 Carriage Mount Kit 81 36,7

47222 918 Only 918 Roll Groover Only 75 34,0

Mounting Kit Only

48292 911 300 Power Drive Mount Kit Only 9 4

48392 912 1822 Carriage Mount Kit Only 39 17,7

48397 914 1224 Carriage Mount Kit Only 36 16,4

48402 915 535 Carriage Mount Kit Only 22 10

CAUTION

Loading...

Loading...