918 Roll Groover

Ridge Tool Company6

NOTE! Support legs are not needed when when using

these stands.

Drive bar must be centered in front chuck

jaws. All bolts must be tight and the drive bar must be

securely held in chuck when closed.

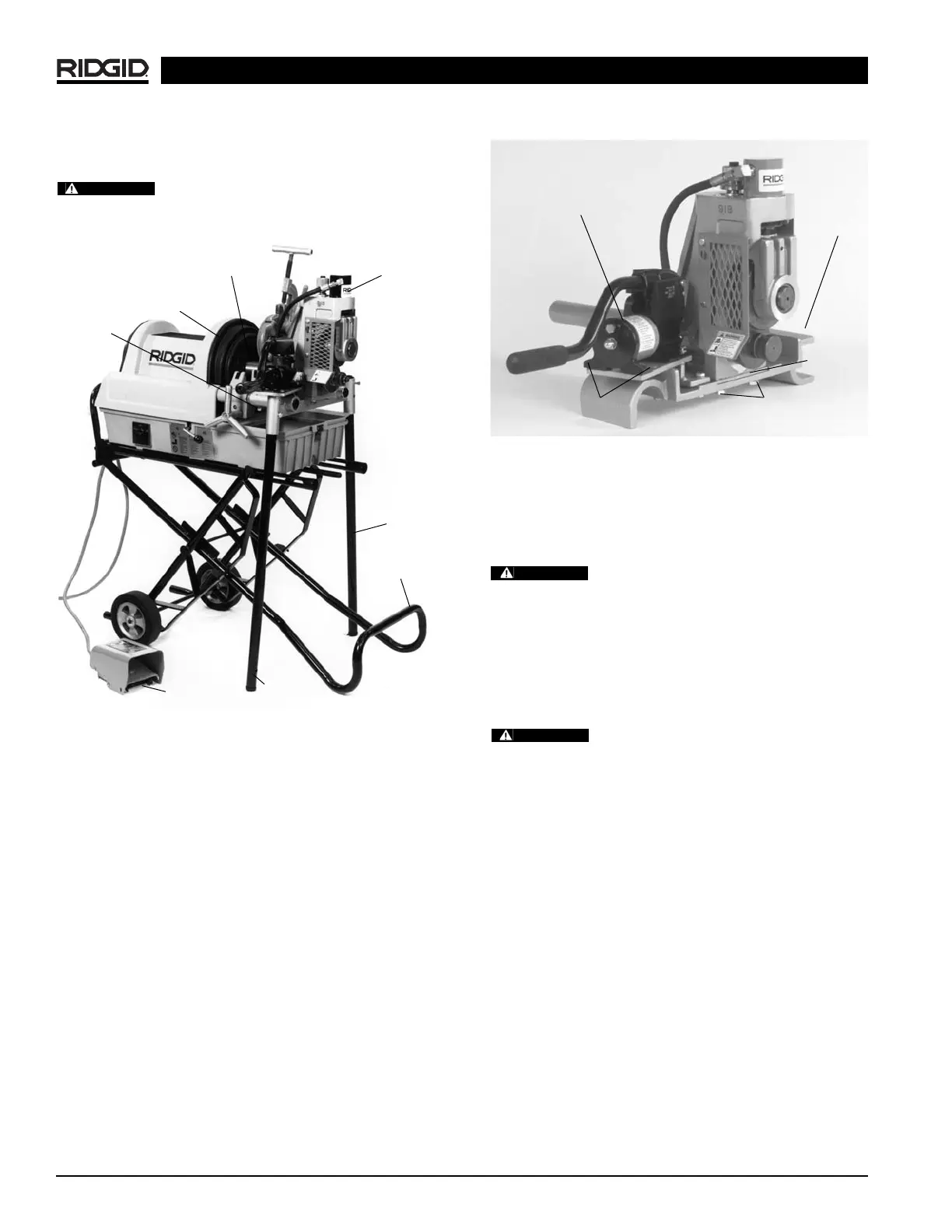

Figure 4 – 918 Roll Groover Mounted on 1822 with 1406

Stand

Installing the 918-4 Roll Groover on the

1224 Threading Machine

Sub-Assembly

1. Align housing plate in recessed area of 1224.

2. Align 918 on the 1224 mounting base.

(Figure 5)

3. Install and tighten the (2)

1

/

2

″ x 1

1

/

4

″ hex bolts which

connect the 918 to mounting base.

4. Attach pump bracket with the two (2)

3

/

8

″ x

1

/

2

″ hex

bolts.

5. Position hydraulic pump and securely bolt in place

with (4)

1

/

4

″ x

3

/

4

″ hex bolts.

6. Attach drive bar adapter to roll groover by tightening

(2) set screws.

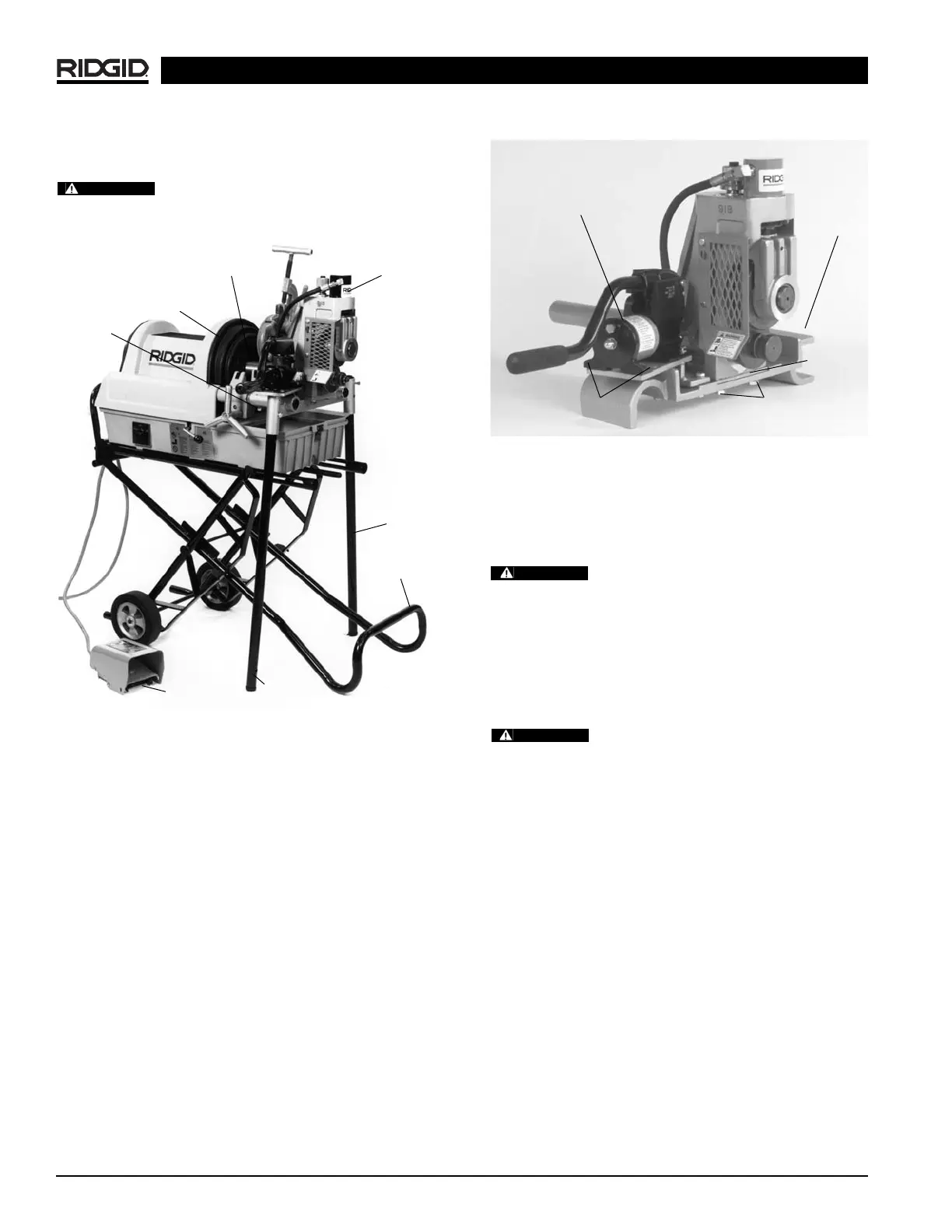

Figure 5 – 918 Heavy Duty Roll Groover on 1224

Threading Machine Mounting Base

Installing on 1224 Threading Machine

1. Position carriage towards front chuck and swing car-

riage tools to rear position.

Position reamer inside the die head to

prevent accidental contact.

2. Place 918-4 on the far side carriage rail and lower

onto near side rail.

(Figure 6)

3. Position base so that the drive bar feeds into the

open chuck.

4. Tighten chuck jaws securely into drive bar.

Drive bar must be centered in front chuck

jaws. All bolts must be tight and the drive bar must be se-

curely held in chuck.

Front Chuck

Foot Switch

Drive Bar

Carriage

918-2

Sub-assembly

Hydraulic Pump

1224

Mounting

Base

1

/

4

″ x

3

/

4

″ bolts (4)

for mounting

hydraulic pump

1

/

2

″ x 1

1

/

4

″ bolts (2)

for mounting base

Support

Leg

Support

Leg

WARNING

1406

Stand

Housing

Plate

CAUTION

WARNING

Loading...

Loading...