22

454107.66.01-02_GB

01.07.2015

Translation of the Original

6. ENVIRONMENTAL REQUIREMENTS

When repairing or placing the process cooler out of service (decommissioning), the

environment-relevant requirements regarding recovery, reuse and disposal of fuels/oils and

components according to DIN EN 378 have to be complied with.

The operator of the process cooler is responsible for the proper disposal of used fuels,

oils and system components.

7. MAINTENANCE

The safety notices contained in Chapter 1 must be complied with !

Always disconnect the process cooler from the mains power supply before attempting

to open the cabinet !

No specific refrigeration technology knowledge is required for the performance of maintenance

activities. This work can be carried out by a properly trained person with appropriate know-

how..

6. Environmental Requirements

7. Maintenance

ENGLISH

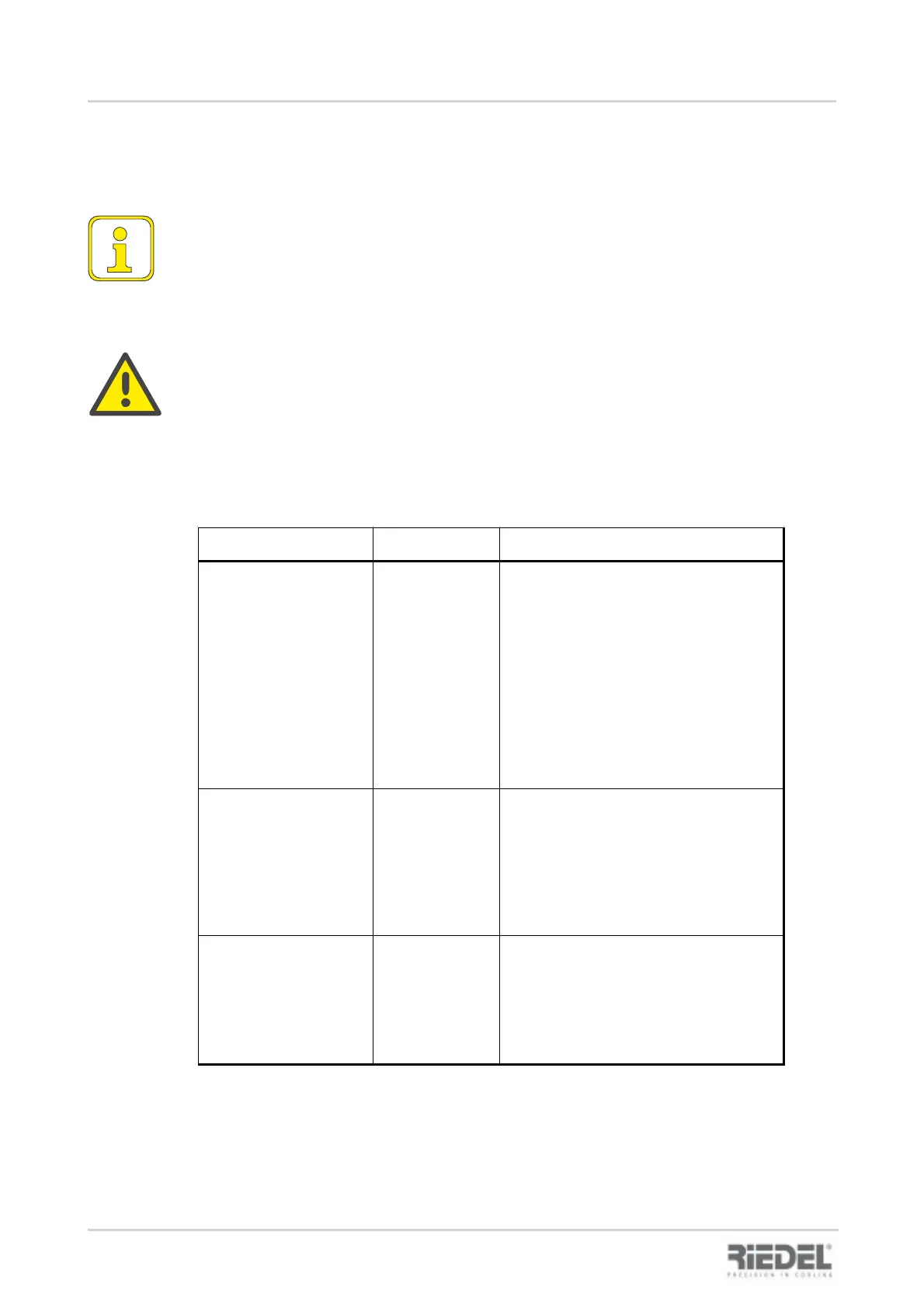

Component Interval Activity

Process cooler

in general

Water circuit

in general

Cooling water circuit

in general

- Check water level, top up

- Visual inspection of the water circuit for

leaks

see Siemens

Service

Instructions

see Siemens

Service

Instructions

see Siemens

Service

Instructions

- Visual inspection of process cooler for

contamination

- Visual inspection of refrigeration circuit

for leaks

- In the case of oil leaks call Siemens

Customer Service

- Visual inspection of the water circuit for

leaks

Loading...

Loading...