21

INSTALLATION

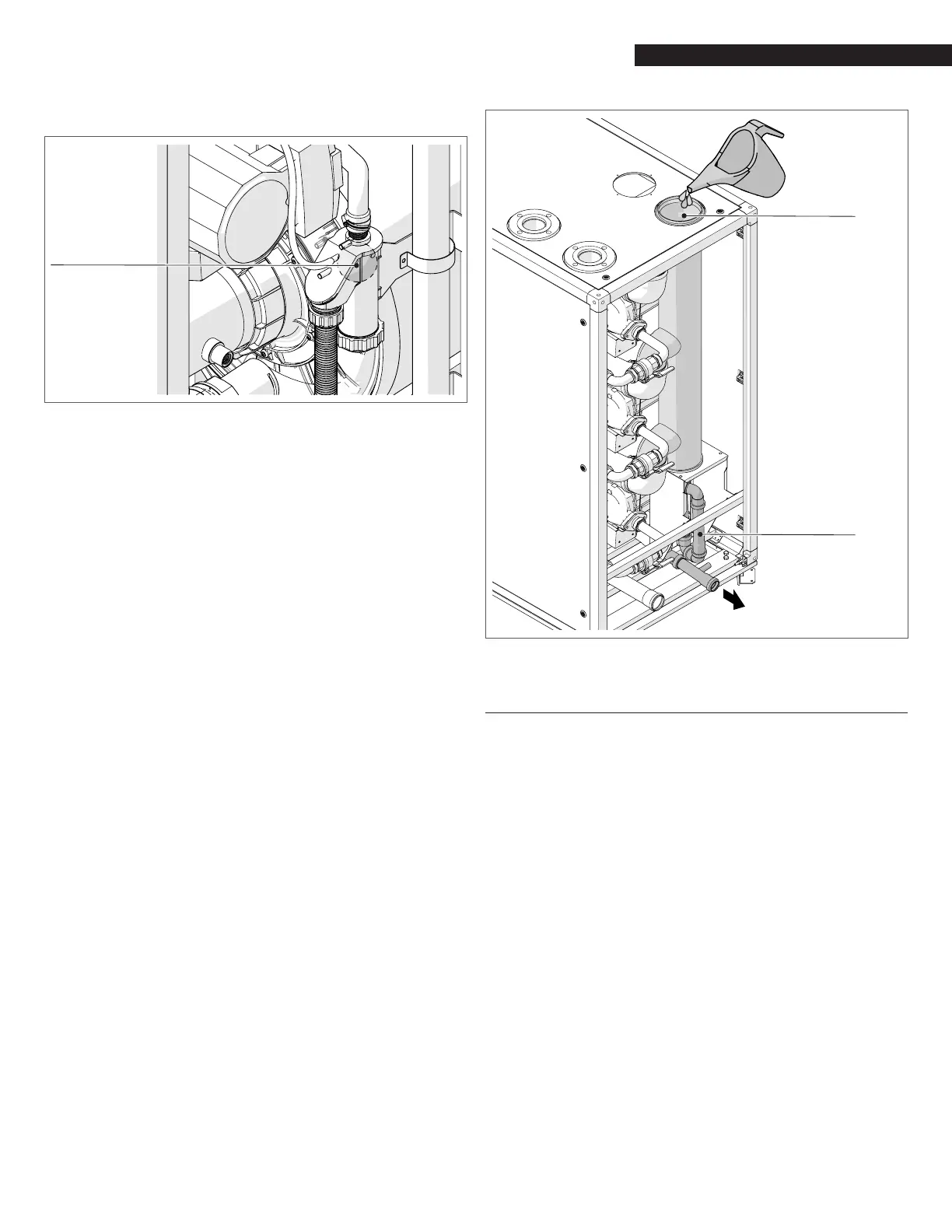

− Reconnect the condensate line to the top of the trap and

securely tighten the hose clamp.

Floating ball

Fig. 18

Reconnect the top connection

− Start the boiler.

NOTE

Repeat this procedure for each condensate trap. It is critical for

bottom modules of AR 1500 (module 3) and AR 2000 (module 4).

Nuisance lockouts may occur if these traps are not completely

lled.

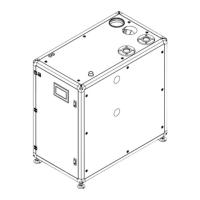

The recommended procedure for lling the siphon at the bottom of

the vertical ue manifold before the start-up or after a prolonged

shutdown is described below:

− Before connecting the external exhaust venting to the

boiler, access the top panel, remove the protective cap from

the ue exit and pour water into it.

− Keep lling the siphon (at least 8 oz. of water are required)

until some water starts owing from the condensate drain

exit.

with water

Syphon

Fig. 19

Filling the siphon

4.12 Gas Supply Piping

Array AR 1000, AR 1500 and AR 2000 boilers contain a 1.5 inch NPT

gas inlet connection on the top of the unit as shown in Fig. 11.

9

WARNING: Never use matches, candles, ames or other

sources of ignition to check for gas leaks.

9

CAUTION: Many of the soaps used for gas pipe bubble-leak

testing are corrosive to metals. Therefore, piping must be

rinsed thoroughly with clean water after leak checks have

been completed.

NOTE: All gas piping must be arranged so that it does not interfere

with the removal of any covers, inhibit service and/or maintenance,

or restrict access between the unit and walls, or another unit.

− Prior to installation, all pipes should be de-burred and

internally cleared of any scale, metal chipss, oil, water or

other foreign particles. Do not install any exible connectors

or unapproved gas ttings. Piping must be supported only

from the oor, ceiling or walls, and must not be supported

by the unit.

− A suitable piping compound, approved for use with natural

gas, should be used. Any excess must be wiped off to

prevent clogging of components.

− To avoid unit damage when pressure testing gas piping,

isolate the unit from the gas supply piping. At no time

should the gas pressure applied to the unit exceed 13.5”

w.c. Leak test all external piping thoroughly using a soap

and water solution or suitable equivalent. The gas piping

used must meet all applicable codes.

Loading...

Loading...