46

SHUTDOWN

46

APPENDIX

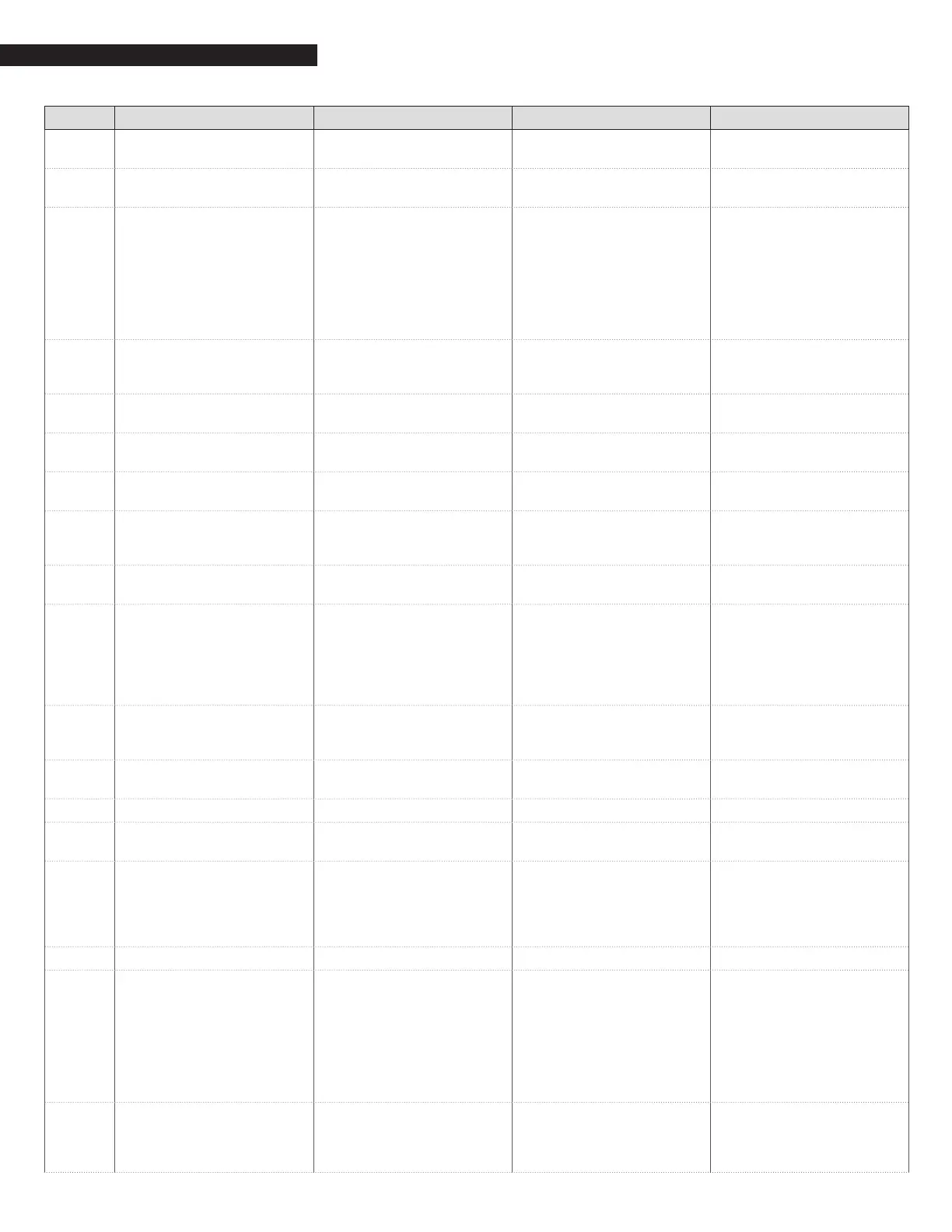

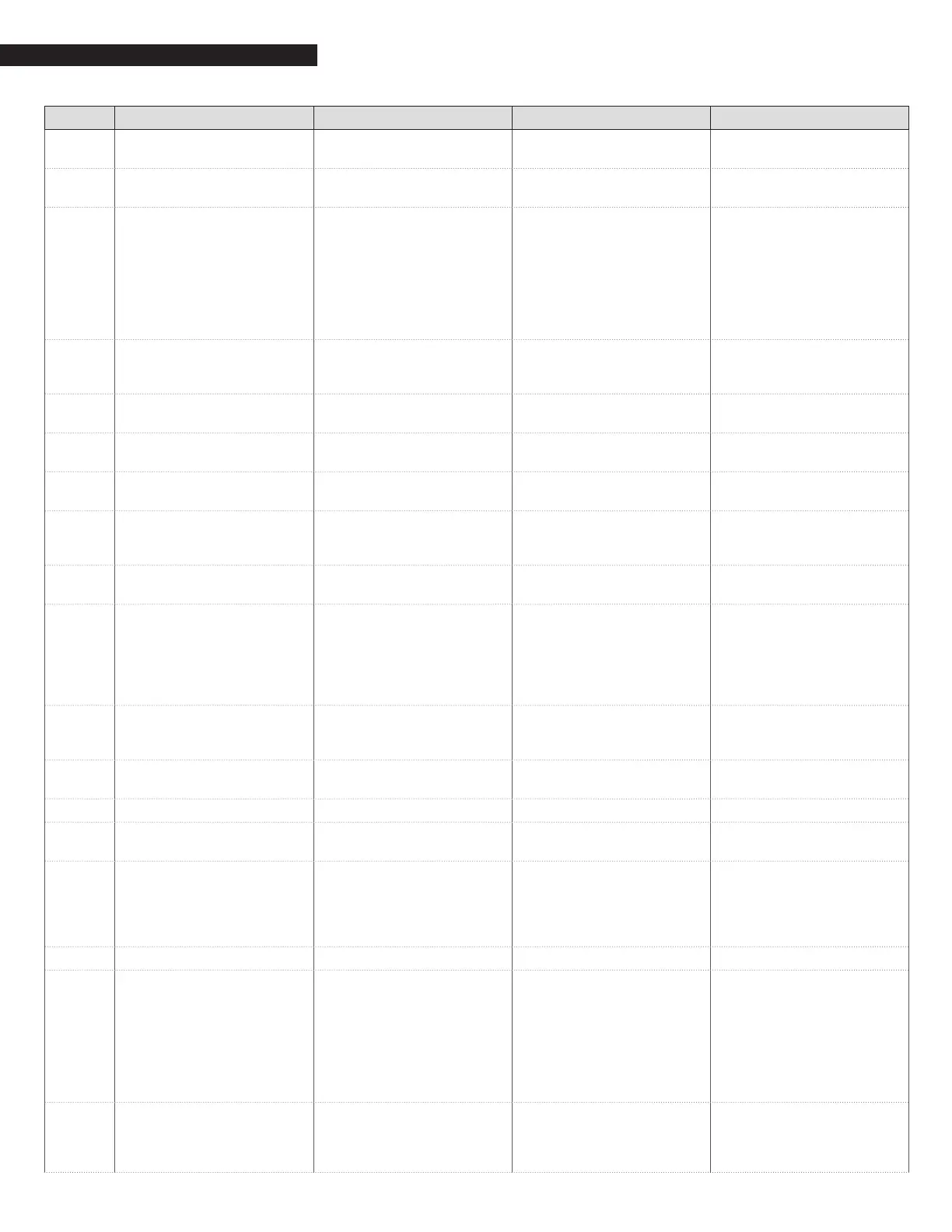

Error no. Error Description Checks Solutions

13 APS_NOT_OPEN Air pressure switch not

working

14 APS_NOT_CLOSED Air pressure switch not

working

15 MAX_TEMP_ERROR The external overheat

protection is enabled or the

T_Supply sensor measures a

temperature of over

100°C (212°F)

a- Check module water

temp.

b- Check the pump to verify

the ow circulation;

c- Check if the valves on

hydraulic circuit are open;

d- Check the high limit

switch.

a- Change the pump or

restart it;

b- Open the valves on

hydraulic circuit;

c- Change the high limit

switch.

16 FLUE_GAS_ERROR Flue temperature exceeded

the maximum ue

temperature

17 STACK_ERROR Internal software error Replace the power control

board

18 INSTRUCTION_ERROR Internal software error Replace the power control

board

19 ION_CHECK_FAILED Internal software error Replace the power control

board

20 FLAME_OUT_TOO_LATE Flame still present 10

seconds after closing the gas

valve

Replace the gas valve

21 FLAME_BEFORE_IGNIT Flame is detected before

ignition

Replace the gas valve

22 TOO_MANY_FLAME_LOSS Three ame failures during

one demand cycle

a- Check the integrity of

the wire connections of the

spark and the earth on heat

exchanger

b- check ionization signal

while running

a- If wires are damaged,

replace them

b- check for proper

combustion settings - if

correct replace spark/

amerod.

23 CORRUPTED_ERROR_NR Error code RAM byte was

corrupted to an unknown

error code

24 FLUE_SWITCH_NOT_CLOSING The blocked ue sensor is

not closed within 10 minutes

29 PSM_ERROR Internal software error

30 REGISTER_ERROR Internal software error Replace the power control

board

33 LWCO_1_ERROR Low Water Cut-Off 1 error a- Check to ensure all valves

are open, pump is running.

b- Check the wiring

between the controller and

the LWCO probe.

a- Verify water is in the

boiler.

b- Verify good connection

between control module

and low water probe.

34 LWCO_2_ERROR Low Water Cut-Off 2 error NA NA

35 GAS_PRESSURE_ERROR Gas pressure switch is open.

This can either be the High

or Low Gas Pressure Switch.

a- Check gas pressure to

ensure it is correct and in

the recommended range for

the unit.

b- Check with as many

modules on as possible to

ensure supply connections

are sized properly.

36 AIR_DAMPER_LOCKING Air Damper feedback is not

received when the relative

output is closed for the

fourth time.

Loading...

Loading...