INSTALLATION

34

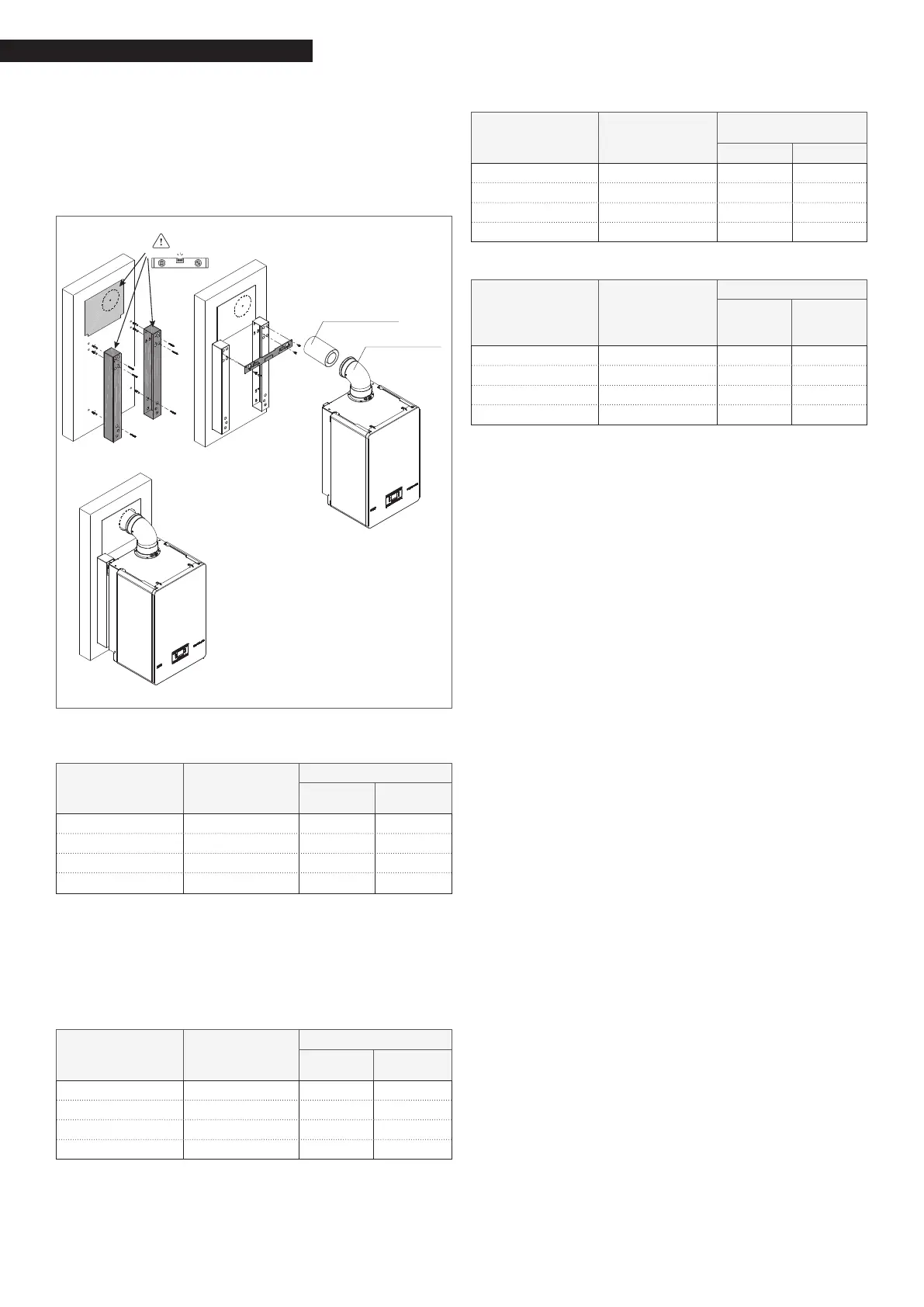

Ø 80-125 CURVE INSTALLATION on CONDEXA HPR 55-70

For this type of installation it is necessary to use the spa-

cer kit for wall xing, available on request.

Prepare the assembly by positioning the ue exhaust car-

dboard template, the spacers and the xing crosspiece as

shown in the gure.

Complete the installation using the bend and extension

Ø 80-125 available as an accessory in the Riello catalog.

BEND 90° Ø80/125 PP/Met

EXTENSION Ø80/125 PP/Met

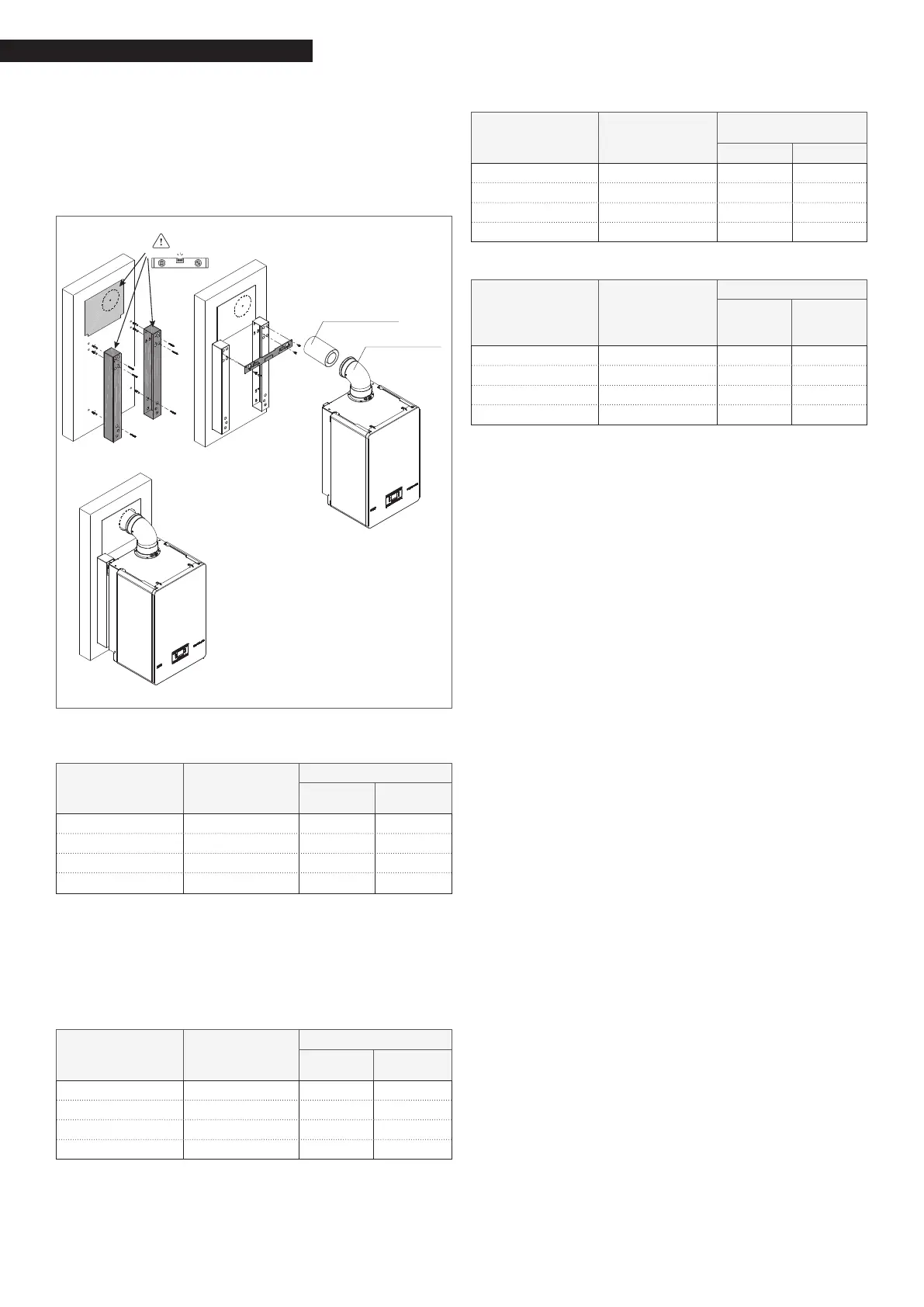

TYPE “B” INSTALLATION

Discharge Ø 80 mm

Model

Maximum

length

Ø 80 mm

Pressure loss

bend 45° bend 90°

Condexa HPR 35 48 m 1 m 1,5 m

Condexa HPR 45 33 m 1 m 1,5 m

Condexa HPR 55 17 m 1 m 1,5 m

Condexa HPR 70 13 m 1 m 1,5 m

With type B installation, the combustion air is taken

from the room and delivered via the openings made on

the rear panel of the appliance, which must be located

in a suitable utility room that is well-aired.

TYPE “C” INSTALLATION

Concentric pipes Ø 80-125 mm

Model

Maximum

length

Ø 80-125 mm

Pressure loss

bend 45° bend 90°

Condexa HPR 35 25 m 1 m 1,5 m

Condexa HPR 45 25 m 1 m 1,5 m

Condexa HPR 55 10 m 1 m 1,5 m

Condexa HPR 70 10 m 1 m 1,5 m

Concentric pipes ø 60-100mm

Model

Maximum

length

Ø 60-100 mm

Pressure loss

bend 45° bend 90°

Condexa HPR 35 10 m 1,3 m 1,6 m

Condexa HPR 45 10 m 1,3 m 1,6 m

Condexa HPR 55 - 1,3 m 1,6 m

Condexa HPR 70 - 1,3 m 1,6 m

Separated pipes Ø 80 mm + Ø 80 mm

Model

Maximum

length

Ø 80+80 mm

Pressure loss

bend 45° bend 90°

Condexa HPR 35 30+30 m 1 m 1,5 m

Condexa HPR 45 21+21 m 1 m 1,5 m

Condexa HPR 55 12+12 m 1 m 1,5 m

Condexa HPR 70 10+10 m 1 m 1,5 m

9

Do not install the ue gas exhaust near ammable

or plastic materials, whose characteristics can be

changed in the presence of high temperatures.

9

The straight length is intended without bends, and

includes the terminals and joints.

9

The boiler is supplied without the ue gas/air suc-

tion kit, as it is possible to use the accessories for

condensing appliances best suited to the installation

characteristics (refer to the catalogue).

9

In the case of use of non-original ue gas exhaust

and air intake ducts, the use of certied ducts com-

pliant with the appliance to which they are connected

must still be guaranteed, with a temperature class

≥120°C and resistant to condensation.

9

To ensure the best installation safety, attach the pipes

to the wall (or ceiling) using specic xing brackets

positioned in line with each joint (at a distance such

that the length of each single extension is not exceed-

ed) and immediately before and after every change of

direction (bend).

9

The maximum pipe length values refer to the ue pipe

accessories available in the catalogue.

9

It is compulsory to use specic pipes.

9

The non insulated ue gas outlet pipes are potential

sources of danger.

9

The use of a longer pipe causes a loss of output of the

boiler.

9

The exhaust pipes can face in the direction most suit-

ed to the installation requirements.

9

As envisaged by current legislation, the boiler is de-

signed to take in and dispose of ue gas condensate

and/or rainwater condensate deriving from the ue

gas discharge system via its own drain-trap.

9

If a condensate relaunch pump is installed, check the

technical output data (provided by the manufacturer)

to ensure it works properly.

Loading...

Loading...