2837

2

GB

➤

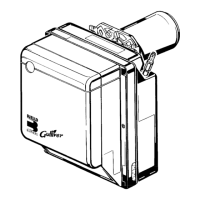

Re-assemble everything following the above in-

structions in reverse order (see fig. 4).

ATTENTION

When the nozzle-holder assembly is re-

assembled, tighten the nut (1) with a torque of

15 Nm, as shown in the figure below.

➤

Replace the control box and tighten the screw (A, fig. 1 page 1) with a torque of 1 - 1.2 Nm.

➤

Connect all the components to the control box as shown in the wiring diagram on page 3.

➤

Stick the specification label next to the one already on the appliance.

TECHNICAL DATA

WORKING FIELD

(as EN 267)

TYPE 364T1

Output - Thermal power 1.7

–

5 kg/h - 20

–

60 kW

Fuel Light oil, viscosity 4 –

6 mm

2

/s at 20 °C

Electrical supply Single phase,

~

50Hz 230V

±

10%

Motor Run current 0.85A – 2750 rpm – 289 rad/s

Capacitor 4

µ

F

Ignition transformer Secondary 8 kV – 16 mA

Pump Pressure: 8

–

15 bar

Absorbed electrical power 0.29 kW

Fig. 4

S7746

1

TIGHTEN WITHOUT MOVING

BACKWARDS TO THE END

D5684

2 3 Light oil output – kg/h

20 30 40 Thermal power – kW

0.8

0.6

0.4

0.2

0

Pressure in combustion

chamber – mbar

D5535

4

50

5

60

1.4

1.7

Loading...

Loading...