3388

7

GB

3.6 ELECTRICAL WIRING

D7198

220/230V ~ 50/60Hz

●

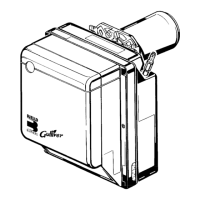

CONTROL BOX

MG569

Main switch

KEY TO LAY-OUT

B5 –2

nd

stage working signal

C – Capacitor

CN1 – Connector ionization probe

E –Electrode

h1 –1

st

stage hour counter

h2 –2

nd

stage hour counter

M –Motor

PA – Air pressure switch

PG – Min. gas pressure switch

RS – Remote reset

SM –Servomotor

SO – Ionization probe

3.6.1 STANDARD ELECTRICAL WIRING

TO BE DONE BY

THE INSTALLER

CARRIED-OUT

IN THE FACTORY

ATTENTION:

³

Do not swap neutral and phase over, fol-

low the diagram shown carefully and

carry out a good earth connection.

³

The section of the conductors must be at

S3 – Remote lock-out signal

(230V - 0,5 A max.)

T6A – Fuse

TB – Burner earth

TL – Limit thermostat

TR –2

nd

stage thermostat

TS – Safety thermostat

V10 – Safety valve

V11 –1

st

stage valve

V12 –2

nd

stage valve

X.. –Plug

XP.. –Socket

least 1mm². (Unless requested otherwise by local standards and legislation).

³

The electrical wiring carried out by the installer must be in compliance with the rules in force in the country

● Connect the 2

nd

stage thermostat (TR) to terminals T6 - T8 and remove the bridge.

TESTING

³

Check the burner has stopped by opening the thermostats.

³

Check that the burner is blocked by opening the connector (CN1) inserted in the probe red wire and located

outside the control box.

NOTES

The burners have been type-approved for intermittent operation. This means they must stop at least once every

24 hours in order to allow the electrical control box to check its efficiency on start-up. The boiler limit thermostat

(TL) normally ensures the burner halts. If this does not happen a time switch halting the burner at least once

every 24 hours must be applied in series to limit thermostat (TL).

Loading...

Loading...