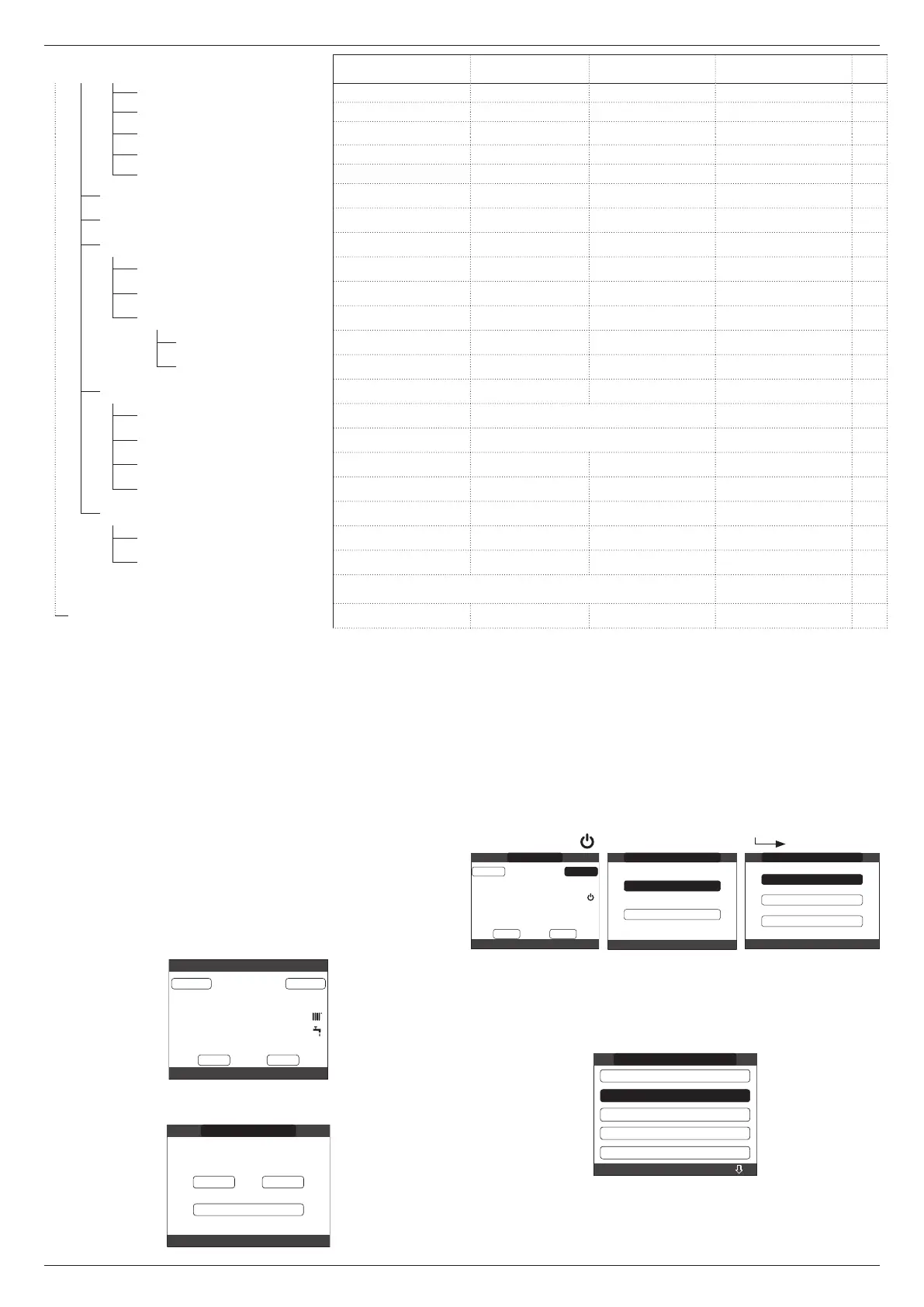

FAMILY

12

MENU

DEFAULT VALUE FACTORY

SET

MINIMUM

VALUE

MAXIMUM

VALUE

ACCESS LEVEL

NOTES

SET

VALUE

BOOSTER DELAY 30min 1 min 60 min INSTALLER

BOOSTER DELTA TEMP 5°C 1°C 20°C INSTALLER

OAT SENSOR TYP

0 0 3 INSTALLER

MINIMUM PUMP SPEED 19% 19% 100% INSTALLER

MAXIMUM PUMP SPEED 100% 19% 100% INSTALLER

ENABLE ERROR HISTORY SERVICE

ERROR HISTORY INSTALLER

SCREED HEATING DEACTIVATE FUNCTION DEACTIVATE FUNCTION ACTIVATE FUNCTION

INSTALLER:

OFF state and

low temperature system

DEACTIVATE FUNCTION INSTALLER

ACTIVATE FUNCTION INSTALLER

FUNCTION SETTINGS SERVICE

TFMIN 20 °C 15 °C 30 °C SERVICE

TFMAX 35 °C 30 °C 55 °C SERVICE

COMBUSTION MONITORING SERVICE

GAS TYPE NATURAL GAS NATURAL GAS / LPG INSTALLER

BOILER TYPE (*) A A / B / C / ..... SERVICE

COMBUSTION OFFSET RESTORE RESTORE RESET SERVICE

ACC AUTO CAL RESTORE RESTORE RESET SERVICE

BOILER INSTALLER

REMOVE BOILER INSTALLER

HYDRAULIC CONFIG 1 0 4 INSTALLER

0 = only heating / 1 = instantaneous with fl owswitch / 2 = instantaneous with fl owmeter /

3 = only heating + water tank with probe / 4 = only heating + water tank with thermostat

SYSTEM INFO SERVICE

(*) BOILER TYPE: see “4.23 Combustion Control Parameters”

4 COMMISSIONING

4.1 Preliminary checks

The rst ignition should be carried out by expert personnel from an authorised Technical

Assistance Service Centre. Before starting up the boiler, check:

- that the data of the supply networks (electricity, water, gas) correspond to the label data

- that the extraction pipes of the ue gases and the air suction pipes are working correctly

- that conditions for regular maintenance are guaranteed if the boiler is placed inside or

between items of furniture

- the seal of the fuel adduction system

- that the fuel ow rate corresponds to values required by the boiler

- that the fuel supply system is sized to provide the correct ow rate to the boiler, and that

it has all the safety and control devices required by current regulations

- that the circulator rotates freely because, especially after long periods of inactivity,

deposits and/or debris can prevent free rotation (see 15.4 “Eventual releasing of the

circulator shaft”).

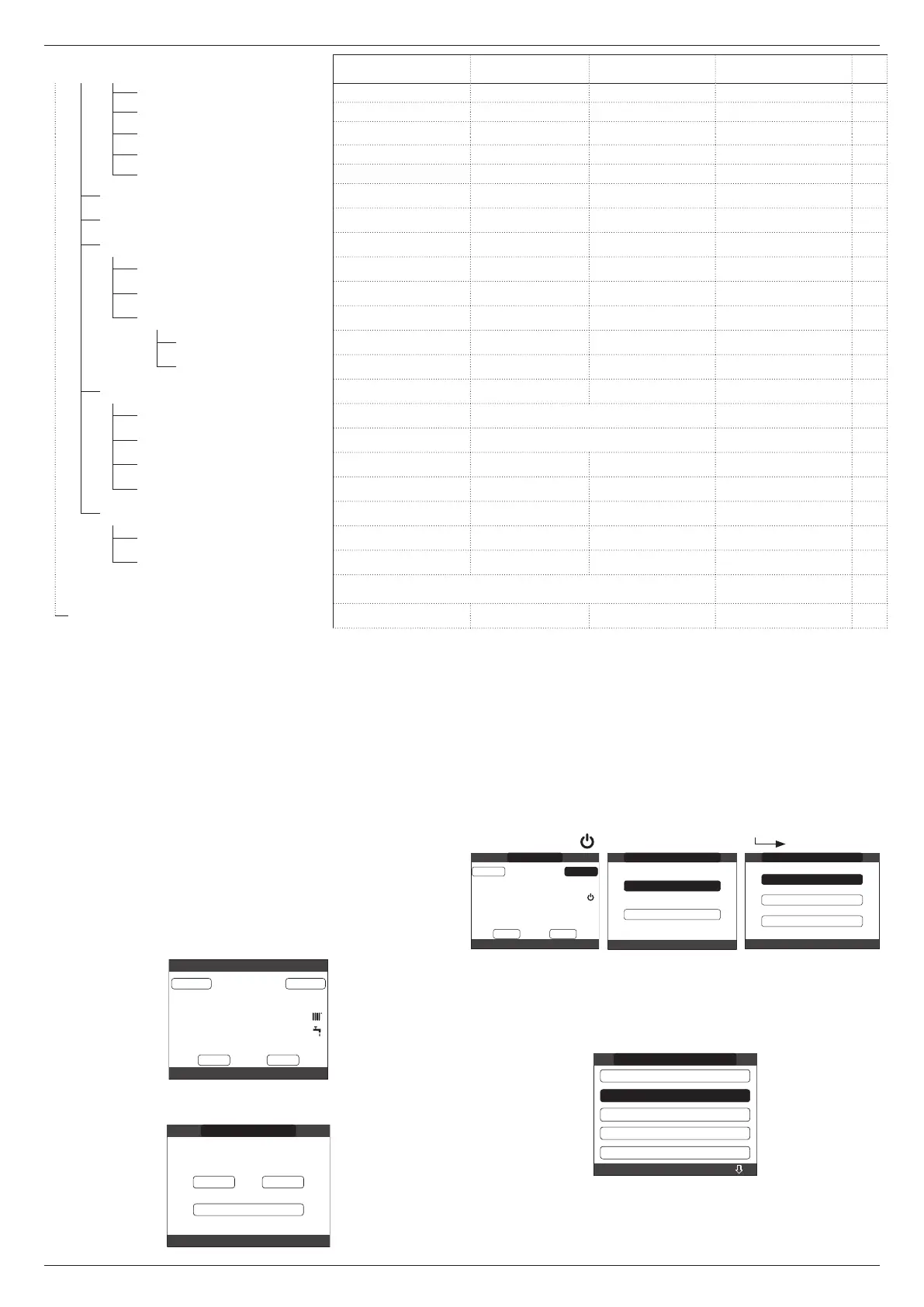

4.2 Programming the boiler

- Position the system’s master switch to the “on” position. The boiler display looks like this:

09/04/2021 12:17

MENU

INFO SET

PLANT

HOT WATER TEMPERATURE

STATE

42

°C

1.3

bar

- In some cases it may be necessary to set the TIME and DATE; in this case the machine

interface request you to carry out the operation with the message “SET TIME AND

DATE”. Navigate with the keys to set the values.

ENTER TIME AND DATE

USE THE ARROWS TO MODIFY

12 17

09/04/2021

:

Note: it is possible to change the TIME and DATE, DAYLIGHT SAVINGS TIME settings, as

well as the LANGUAGE and the duration of the back-lighting, even afterwards by entering

the MENU from the main screen and then selecting SETTINGS.

Note: The device automatically manages the change of time from solar to daylight savings

time and vice versa.

b

Each time that the boiler is powered an automatic venting cycle is carried out lasting

4 min. To interrupt the vent cycle, carry out the procedure explained in “4.3 First

commissioning”.

- Set the boiler to OFF selecting, from REC10CH, STATE BOILER.

42

°C

MENU STATE

SETINFO

1.3

bar

09/04/2021 12:17

BOILER

MAIN ZONE

OFF

HOT WATER ONLY

HEATING AND HOT WATER

BOILER

- Through the REC10CH it is possible to access, using the TECHNICAL menu, a series

of parameters that can be programmed to allow you to personalise the operation of the

boiler based on the type of system.

There are 3 access levels: USER, INSTALLER and

SERVICE (see “3.1 Structure of the MENU tree of the REC10CH”).

- Access the parameters and set the operation according to your type of system

.

4.2.1 Boiler conguration

- Select PARAMETERS.

PARAMETERS

WEATHER COMPENSATION

INSTALLATION

RANGE RATED

CALIBRATION

Loading...

Loading...