13

Shrink-wrapping a loaded pallet

Ask your film supplier for the operating

instructions.

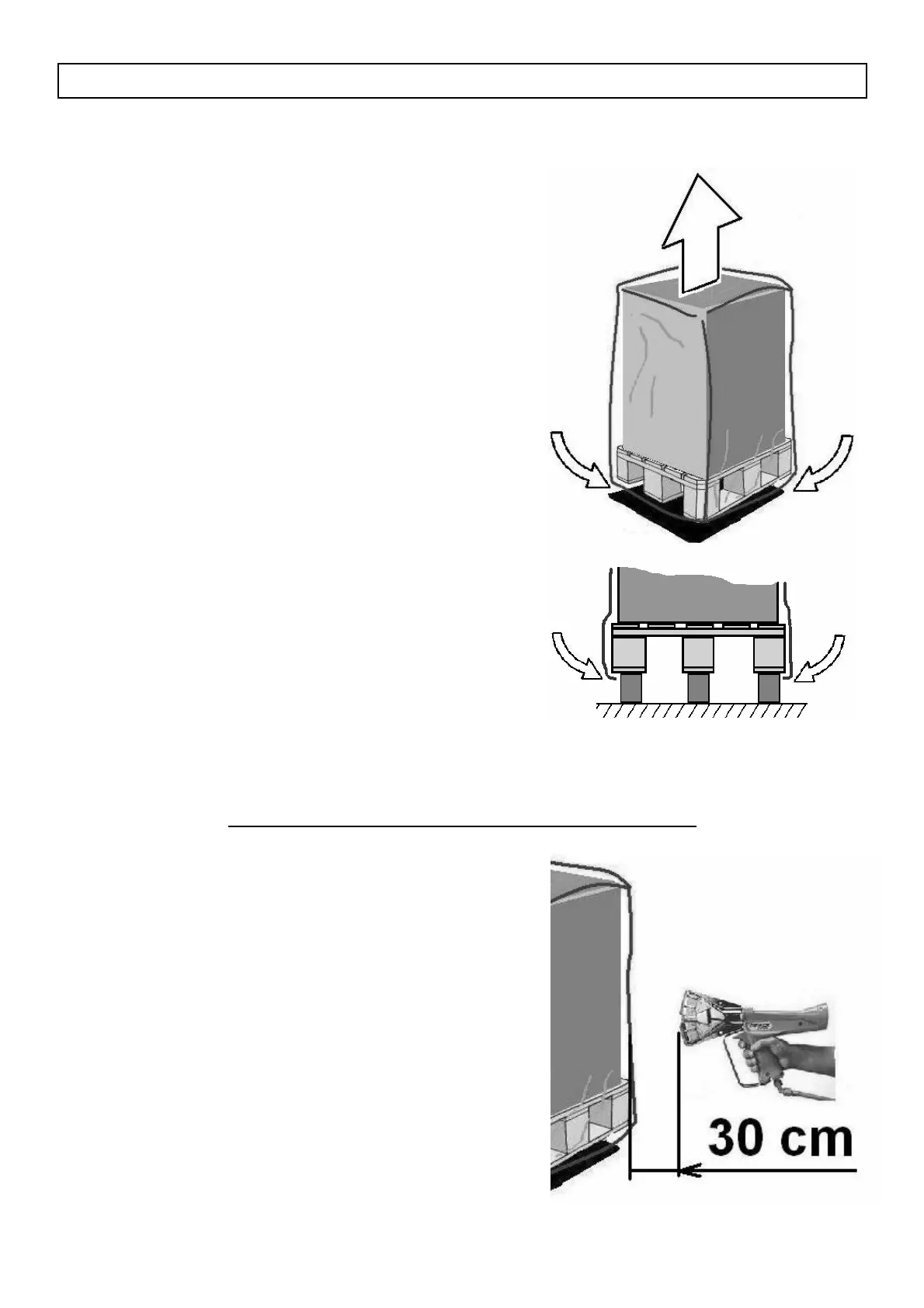

The pallet must be lifted so that the four

corners are accessible: the purpose of this is

to allow the film to be shrunk under the pallet

and so ensure very strong cohesion between

the pallet and the load it supports. You will find

an accessory in the RIPACK product range

that is designed specially to keep pallets lifted

from the ground: the CALPACK (contact your

dealer).

Slide the shrink cover, which must be about

5% wider than your pallet and sufficiently long

to be able to be shrunk under the pallet (H plus

200 mm).

Ignite your RIPACK 2200 as explained in the

chapter "Operation".

SHRINK-WRAPPING RECOMMENDATIONS

(in the absence of instructions provided by the

film manufacturer):

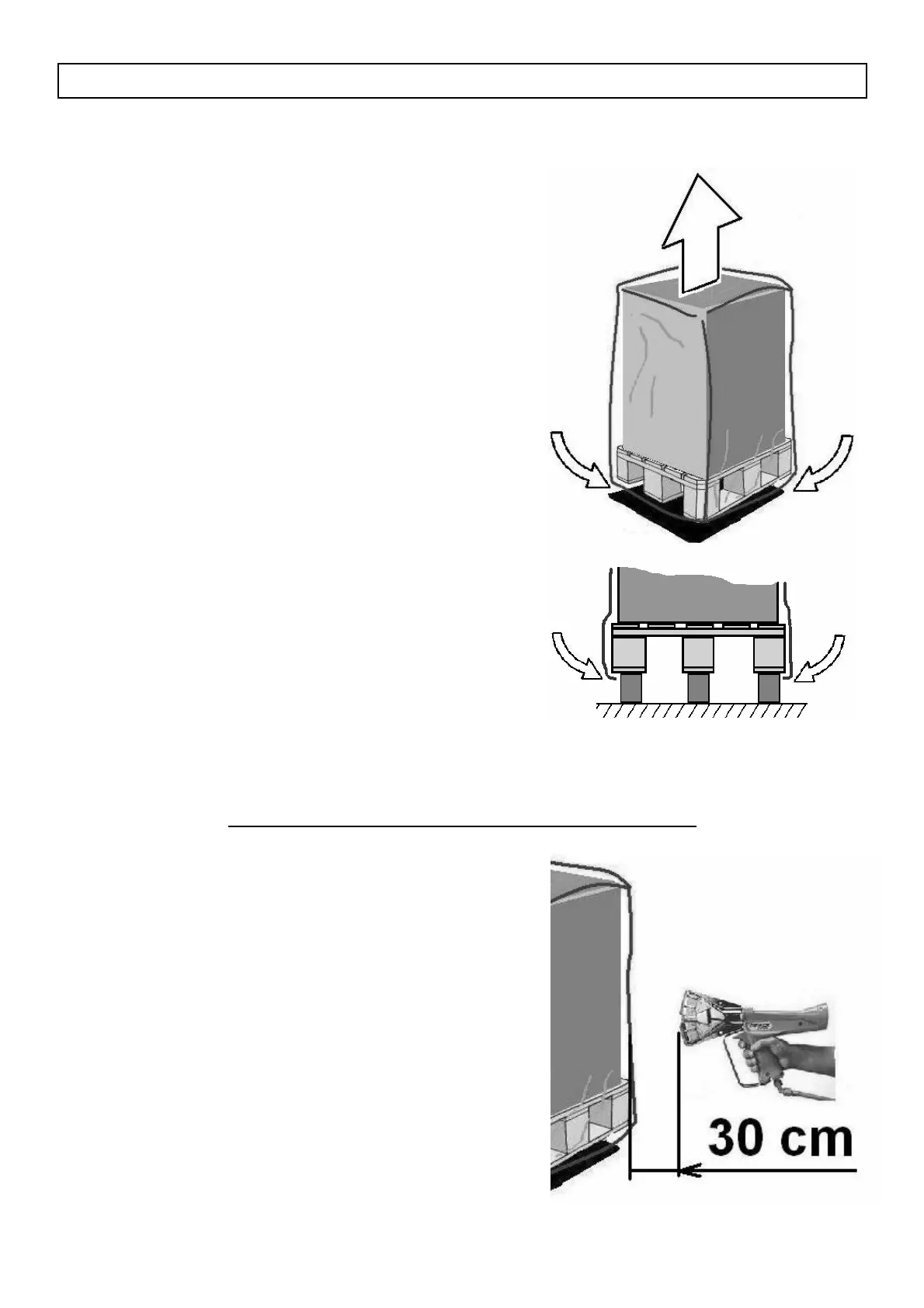

Remain at a distance of at least about

30 centimetres from the film and start shrink-

wrapping the lower part of the four sides so the

pallet is shrink-wrapped underneath. Make

sure you point the air flow perpendicularly

along the sides of the pallet.

Apply the heat in a continuous movement and

at a constant speed.

NEVE R STAY O N THE SAM E SPO T.

EXAMPLES OF USE

Loading...

Loading...