14

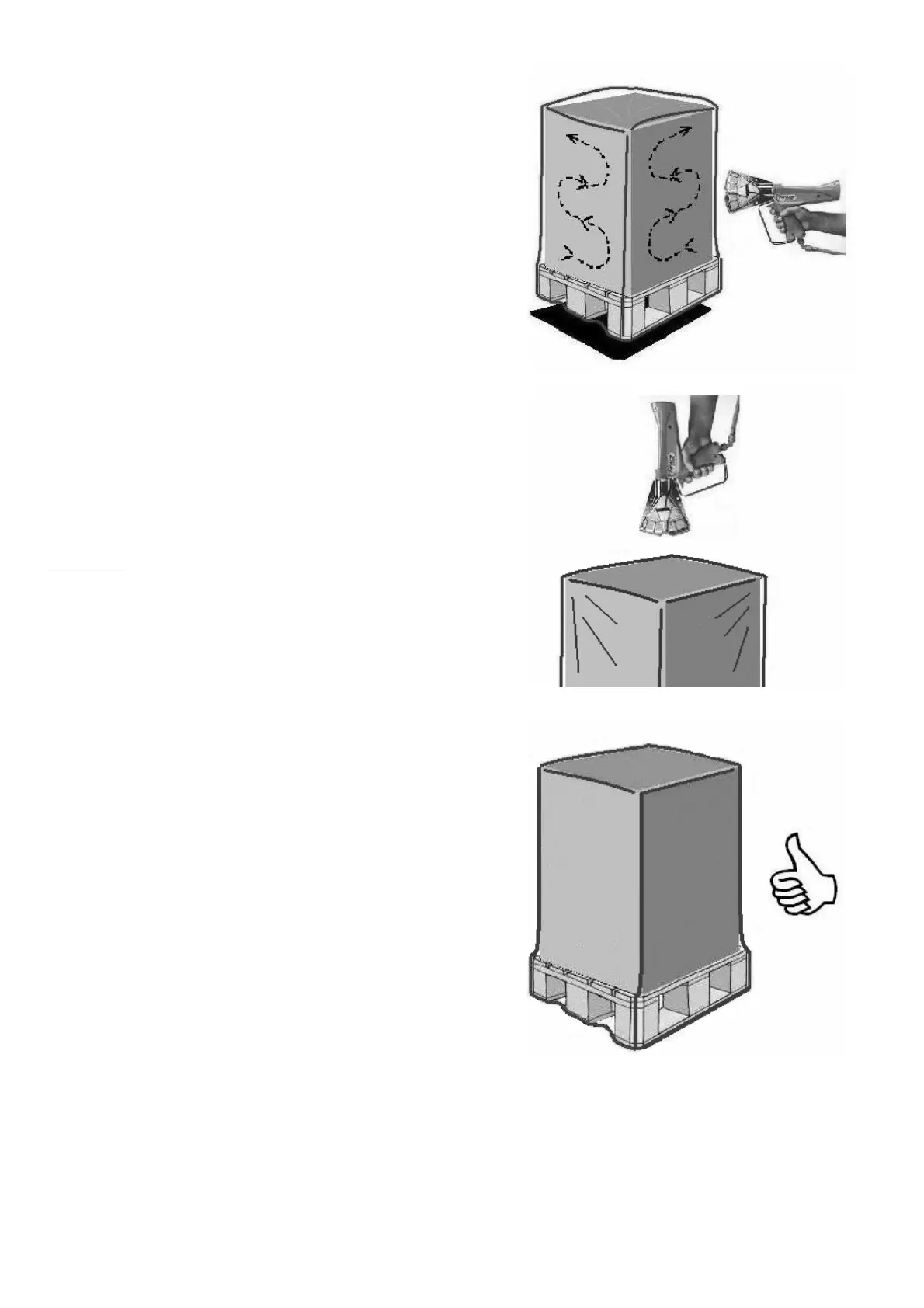

The various films react differently, so you

must observe the reaction and adapt your

speed and movement and/or the distance

between the nozzle and the film accordingly.

You can also adjust the power of the

RIPACK 2200 with the adjustable

SECURIPACK controls.

Once the lower part of the pallet has been

shrink-wrapped, continue the operation for

each side and move from top to bottom to

cover the entire height.

Once the 4 sides have been shrink-

wrapped, you can do the top by applying the

hot air to the top of the pallet.

Caution: The film is already stretched along

the sides so you should apply less heat on

the top in order to prevent the cover from

being damaged.

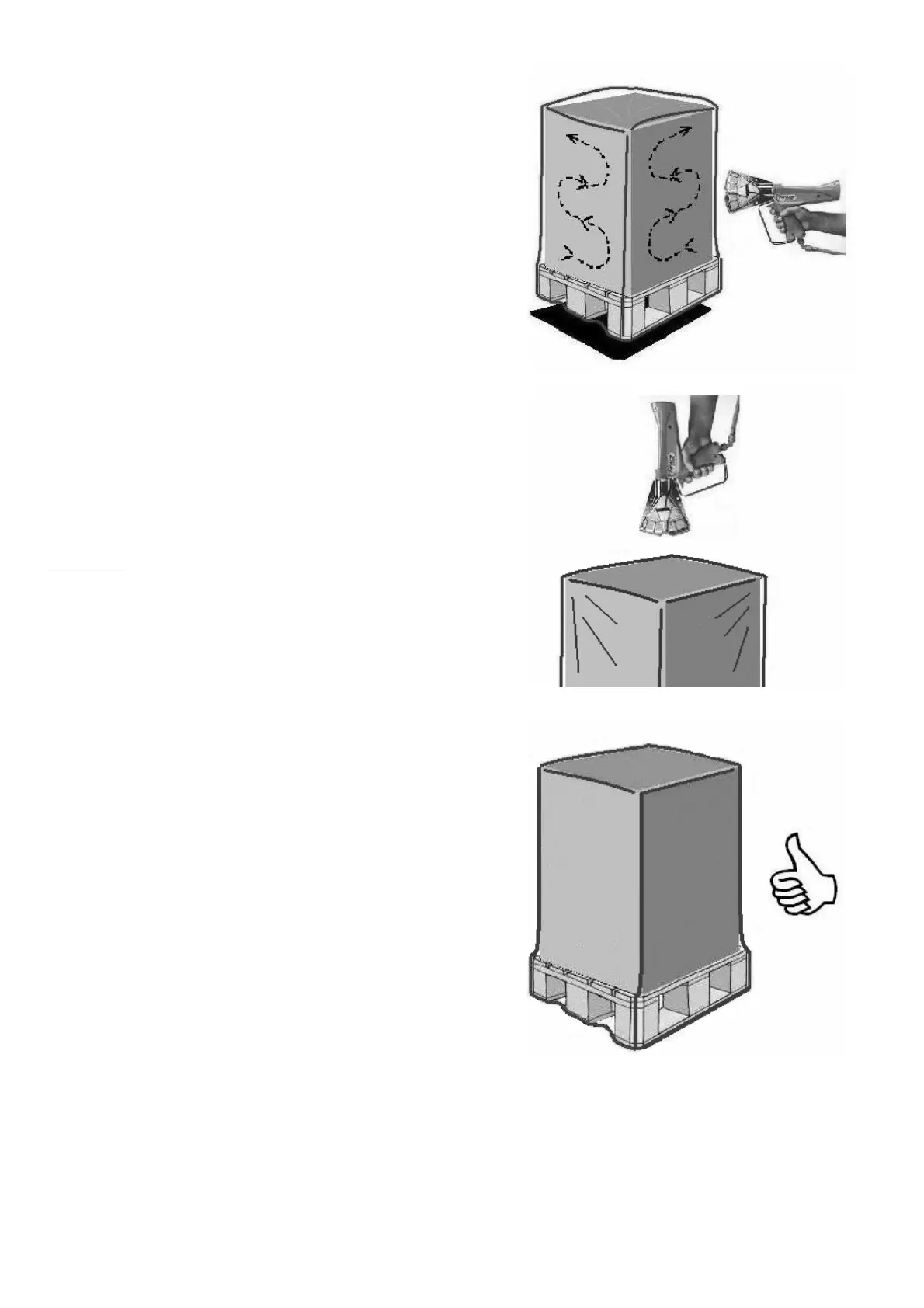

When you have stopped applying heat with

the gun, the plastic film, because of its

make-up, will continue to shrink for some

time. This time will vary depending on the

quality, the thickness and the type of load

that has been wrapped. It is recommended

therefore that you wait until the cover has

cooled off and everything is tight before

moving the pallet.

After cooling and before storage, always

check that the cover and the wrapped

goods are in good condition.

CHE CK C ARE FUL LY FO R AT LE AST 2 HO URS

AFT ER SH RI NK- WR APP ING

Loading...

Loading...