Choke System

Figures

6-3

and

6-4

1.

Remove screws to remove choke valve and

choke shaft. Use care to avoid damaging

parts.

2.

During reassembly, install with cut-out on valve

facing main air jet.

Idle

System

Figures

6-3

and 6-4

1.

Remove idle jet. Use care to avoid damaging

parts.

NOTE: Idle jet is included in repair kit.

2.

During reassembly, tighten idle jet securely to

prevent fuel leakage.

Main

Fuel System

Figures

6-3

and 6-4

1.

Drain remaining fuel in fuel bowl into a suitable

container. Remove bowl and gasket.

2.

Remove main jet from carburetor body.

NOTE: Main jet is included in repair kit.

3.

During reassembly, tighten main jet securely to

prevent fuel mixture from becoming too rich.

Install fuel bowl and new gasket. Torque screw to

specifications (see 'SPECIFICATIONS').

Float System

Figures

6-3

and 6-4

1.

Remove float pin, float and needle valve.

NOTE: Float pin is flattened at one end. Use a small

drift punch and tap on float pin round end

to remove.

r

2.

Inspect float. Replace

if

dented, contains fuel, or

if

float

axle

bearing and tab contacting needle

valve are worn excessively.

NOTE: Special service needle valve is included in

repair kit.

Inspect needle valve. Replace

if

damaged or worn.

3.

During reassembly, adjust float setting. With float

chamber bowl removed, place carburetor body

on end. Float surface must be parallel to car-

buretor body. To adjust float surface bend tab.

The tab (float lever) should just contact the fuel

needle valve.

Install float bowl using a new gasket. Torque to

specifications (see 'SPECIFICATIONS).

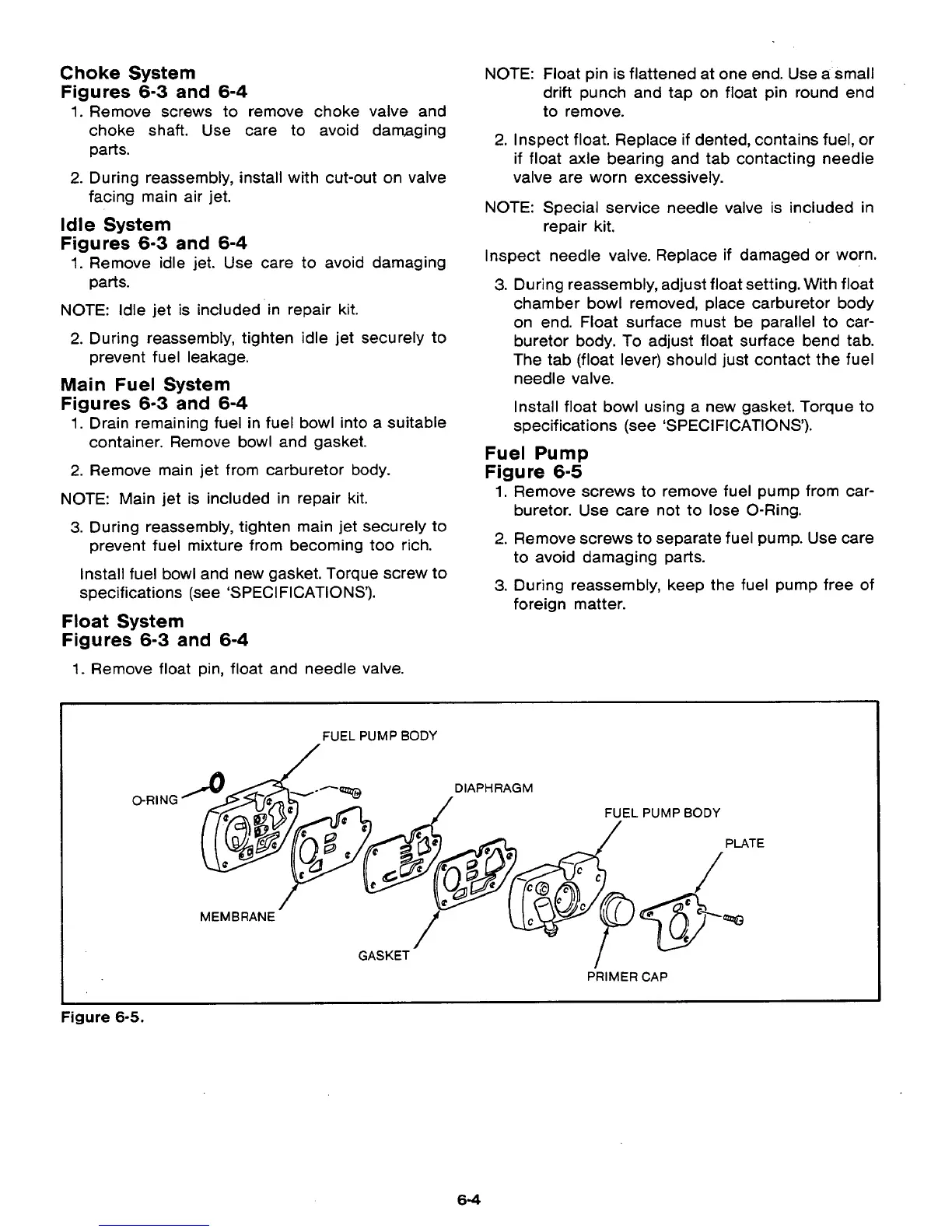

Fuel Pump

Figure

6-5

1.

Remove screws to remove fuel pump from car-

buretor. Use care not to lose 0-Ring.

2.

Remove screws

to

separate fuel pump. Use care

to avoid damaging parts.

3.

During reassembly, keep the fuel pump free of

foreign matter.

"

FUEL

PUMP BODY

O-RING

DIAPHRAGM

MEMBRANE

GASKET

PRIMER CAP

Figure

6-5.

,."

64

Loading...

Loading...