6-3-11

CONNECTING

ROD

and

PISTON

1)

Straighten

out

the

bent

tabs

of

rod lock washer and remove

bolts

from connecting rod.

2)

Take off

oil

scraper, rod

lock

washer and connecting

rod

cap..

3)

Scrape off

all

carbon deposits

that

might interfere with removal

of

piston from upper end of

4)

Turn crankshaft until piston is

at

top, then

push

connecting

rod

and piston assembly

upward

5)

Remove piston from connecting rod by taking out

two

clips and then removing

the

piston

6)

Remove piston rings from piston by widening

the

open ends.

cylinder.

and

out

through top

of

cylinder.

pin.

7)

a)

b)

*

*

In

reassembly;

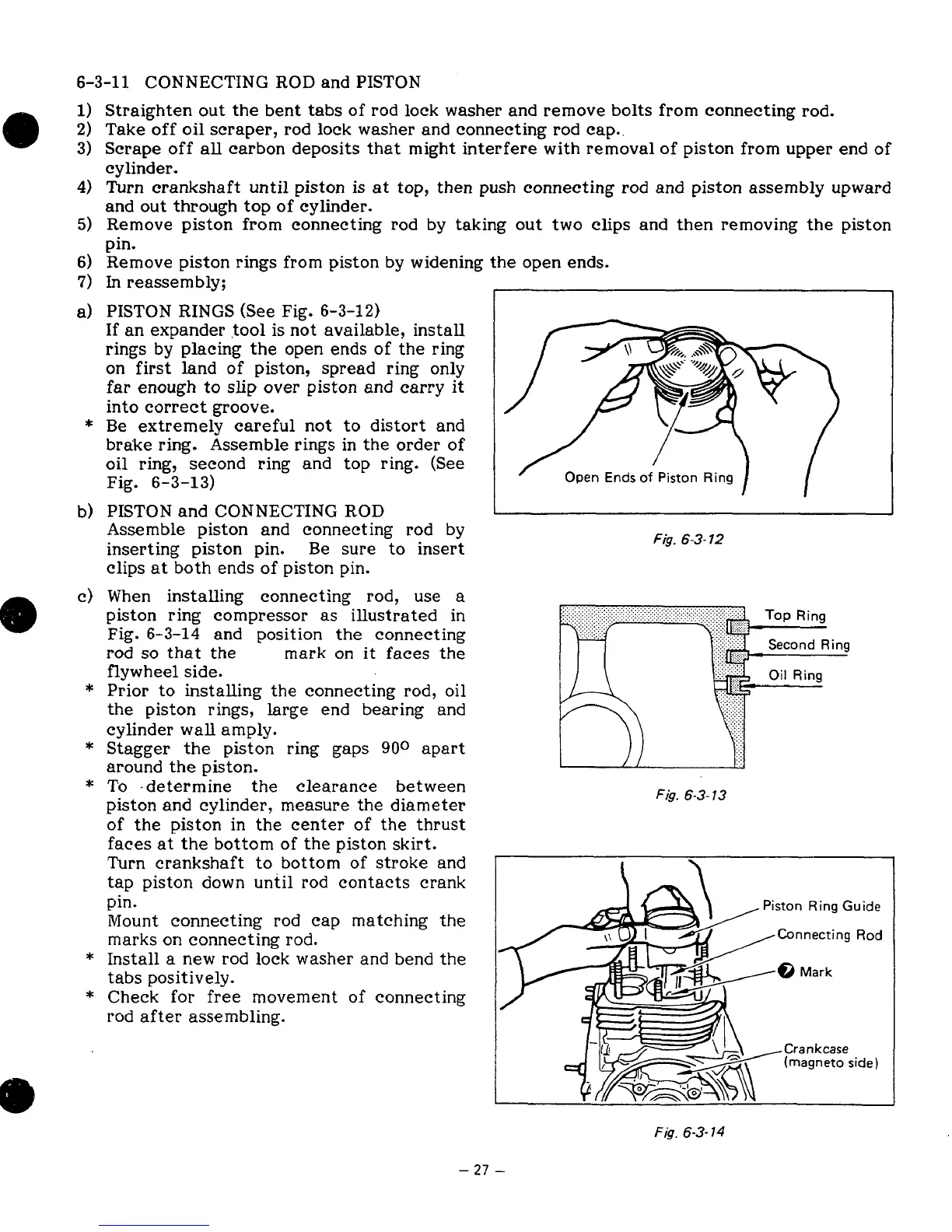

PISTON RINGS (See Fig.

6-3-12)

If an expander

tool

is not available, install

rings by placing the open ends

of

the

ring

on first land

of

piston, spread ring only

far enough

to

slip

over piston and carry it

into correct groove.

Be extremely careful not

to

distort and

brake ring. Assemble rings in

the

order

of

oil

ring, second ring and top ring. (See

Fig.

6-3-13)

PISTON and CONNECTING

ROD

Assemble piston and connecting rod

by

inserting piston pin. Be sure

to

insert

clips

at

both ends of piston pin.

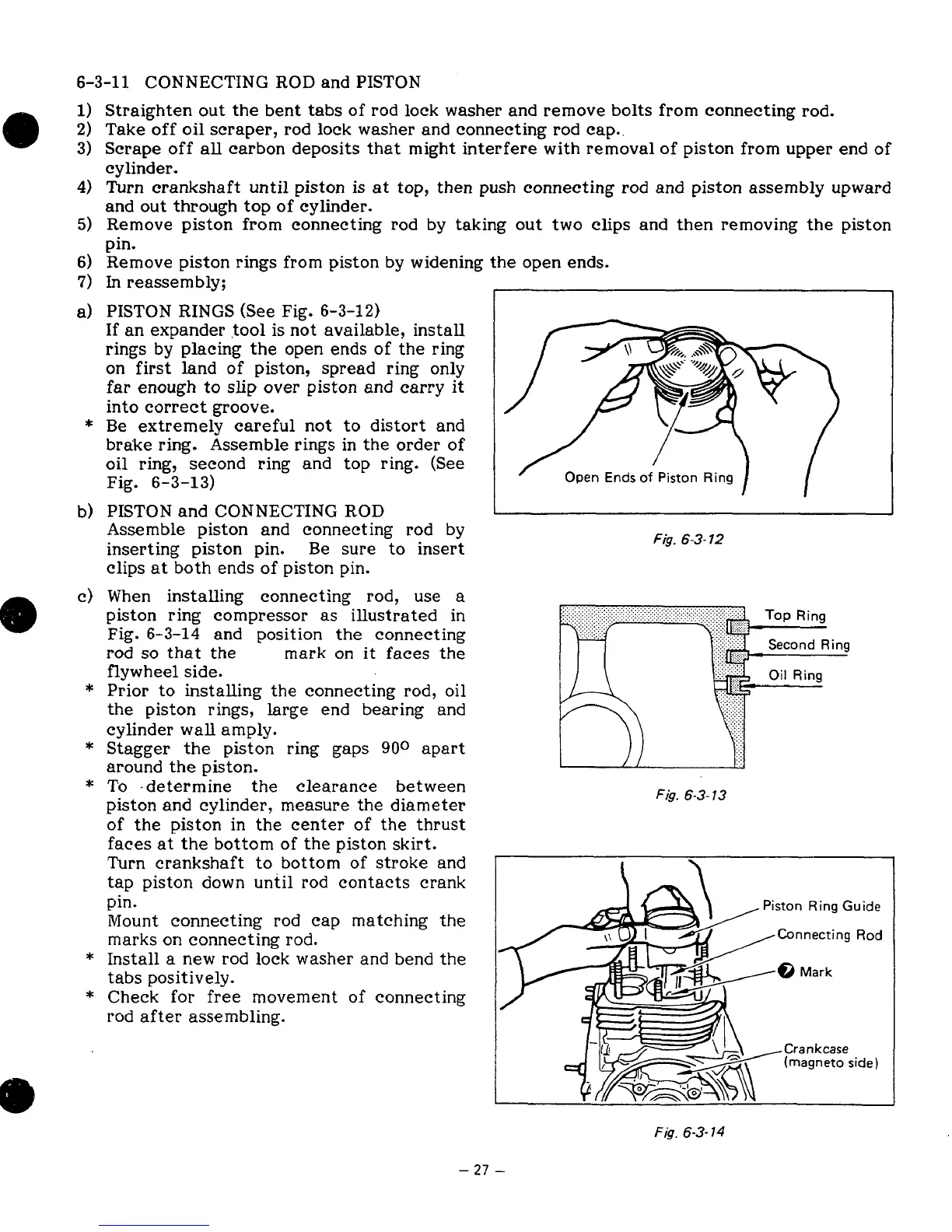

When installing connecting rod, use

a

piston ring compressor

as

illustrated in

Fig.

6-3-14

and position

the

connecting

rod

so

that

the

mark

on

it

faces

the

flywheel side.

Prior

to

installing

the

connecting rod, oil

the piston rings, large end bearing and

cylinder wall amply.

Stagger the piston ring gaps

900

apart

around

the

piston.

To

.determine

the

clearance between

piston and cylinder, measure the diameter

of

the piston in the center

of

the

thrust

faces

at

the bottom

of

the piston skirt.

Turn crankshaft

to

bottom of stroke and

tap piston down until rod contacts crank

pin.

Mount connecting rod cap matching

the

marks on connecting rod.

Install

a

new rod

lock

washer

and

bend the

tabs

positively.

Check

for

free

movement

of

connecting

rod after assembling.

Fa.

6-3-

12

.......

.......

.......

.......

!"&

Oil

Ring

.......

F

is.

6-3-

13

/I

I

F

is.

6-3-

13

Second

Ring

...

...

...

Piston

Ring

Guide

Fig.

6-3-

14

-

27

-

Loading...

Loading...