Do you have a question about the Robopac ECOWRAP PLUS XL FRD and is the answer not in the manual?

Explains the manual's aim: operator guidance for risk prevention and minimization.

Defines danger, caution, and important symbols for user safety and information.

Defines recurring terms and roles such as Operator, Maintenance Technician, and Installer.

Explains pictograms for generic danger, live parts, flammable material, moving parts, etc.

Explains pictograms for no smoking, no naked flames, no pedestrians, do not insert hands.

Explains pictograms for wearing gloves, goggles, helmet, safety shoes, and using manual.

Provides instructions on how to contact Robopac for technical support and spare parts.

Lists documentation provided with the machine, including manuals and software.

Emphasizes reading instructions, understanding warnings, and preserving safety signs.

Lists specific examples of misuse and prohibited actions for the machine.

Details employer responsibilities regarding operator training and documentation.

Details risks of impact, shearing upper limbs, and body crushing during operation.

Covers risks of falling, falling packages, tripping, and falling/ejected objects.

Provides safety guidelines for performing adjustments and maintenance.

Specifies ambient temperature, humidity, EMI immunity, and environmental conditions for electrical safety.

Identifies and explains various danger, prohibition, obligation, and information signs on the machine.

Defines operator standing, maintenance access, loading/unloading, and machine operating areas.

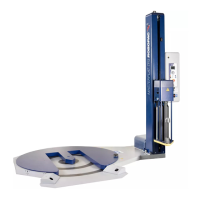

Describes the machine as a semi-automatic pallet wrapper, its components, and intended use.

Details key machine components like the rotary arm, arm motor, safety edges, and control panel.

Compares features of different machine models (FR and FRD).

Details the four phases of the wrapping operation cycle from pallet placement to unloading.

Explains the function of safety devices like the main switch, emergency stop, key-operated switch, and sensible edges.

Identifies electrical devices such as gearmotors, limit switches, photocells, and inductive sensors.

Describes optional accessories like reel-holder shafts and autotransformer units.

Details accessories such as longitudinal stop devices, work area barriers, and roll container stops.

Covers template positioning for work areas and mobile base installation.

Lists specifications like supply voltage, power, speed, weight, operating temperature, and foundation requirements.

Details film spool dimensions, thickness, and maximum weight for the machine.

Presents dimensional specifications (A-M) for various Ecowrap and Masterwrap models.

Specifies requirements for ambient temperature, perimeter space, and environmental conditions.

Provides recommendations for safe handling and loading of the machine.

Explains machine packaging types and instructions for safe unpacking and component checking.

Describes various transport methods and the importance of anchoring the machine during transit.

Emphasizes checking the center of gravity before lifting and safe practices with forklifts.

Details initial steps for machine installation, including cutting straps and removing transport brackets.

Guides on safely lifting the column using a lifting device and avoiding tipping.

Covers positioning, drilling, securing the base with plugs, and leveling the machine.

Details removing the lifting device, fitting the film carriage, and making electrical connections.

Provides instructions for installing optional front and longitudinal stop devices.

Details the installation of the optional work area delimitation barrier.

Guides on installing the optional stop device for correct positioning of roll containers.

Covers template positioning for work areas and mobile base installation.

Details the assembly and installation of the optional pallet lifting frame.

Provides general recommendations for making machine connections.

Guides on checking voltage/frequency and connecting the power cable and earth wire.

Provides safety and procedural recommendations before making adjustments.

Details adjustments for film stretch on the carriage.

Explains how to adjust the reel brake for film tensioning.

Guides on adjusting the wrapping machine arm drive chain tension.

Explains how to adjust the film carriage belt tension for optimal performance.

Provides key recommendations for safe and effective machine operation.

Identifies and explains controls for Ecowrap Plus, including emergency stop, cycle start, and selector.

Describes how to access and modify machine functions using the multi-function selector.

Explains navigation modes (P, R, PH) and functions like wrapping cycles and photocell selection.

Covers settings for carriage height, speed, manual controls, and rotation speed adjustments.

Details using the selector for cycle selection, parameter changes, manual carriage control, and reinforcing wrapping.

Explains how to view production data like cycle counters and software revision.

Explains programming the "Eco" wrapping cycle via self-learning.

Guides on turning the machine on using the main switch and reset button, and turning it off.

Details how to start, stop, and temporarily suspend wrapping cycles on the Ecowrap Plus.

Explains how to activate the emergency stop button and restart the machine safely.

Identifies and explains controls for Masterwrap Plus, including emergency stop, cycle start, and selector.

Details the Masterwrap Plus UI, selector, display, and page edge color meanings.

Presents the main menu options and their corresponding functions on the machine interface.

Details how to select "Double wrapping", "Single wrapping", and "Double wrapping with feeder" cycles.

Describes how to view the arm rotation speed (rpm) on the machine interface.

Explains how to display carriage speed, upstroke speed, and downstroke speed.

Details viewing wrapping end delay (cm) and set pallet height.

Guides on accessing and using manual controls for carriage and arm movements.

Describes viewing film tensioning values for lower, upstroke, upper, and downstroke.

Explains functions like "Copy recipe" and "Ergonomic upstroke", and carriage stop height selection.

Guides on accessing settings for cycle counter, acoustic signal, user login, panel lock, and device status.

Covers load cell settings, assistance pages, and returning to the previous menu.

Explains viewing counters, acoustic signal ON/OFF, and password management for panel lock.

Details changing the panel lock password and setting CELL/OFFSET values.

Guides on accessing and using recipes (Programmes 1-6) for machine configuration.

Explains how to access and use the manual cycle.

Explains how to access and use the Eco cycle.

Guides on accessing and setting parameters for the manual cycle.

Details carriage and arm movements during the manual cycle operations.

Guides on accessing the self-learning cycle Home page for the Eco cycle.

Explains how to start the logging mode and set parameters for the Eco cycle.

Details arm turning, movement execution, and control confirmation in Eco cycle logging.

Explains miscellaneous functions like Reset button, Cycle Start, and emergency bypass.

Guides on turning the Masterwrap Plus machine on and off using the main switch and reset button.

Details selecting, viewing, and modifying recipe parameters for the machine.

Explains how to select and perform a single wrapping cycle.

Details selecting and performing the double wrapping cycle for load stabilization.

Guides on selecting and performing the wrapping cycle with a feeder for enhanced protection.

Details starting, stopping, and suspending cycles on the Masterwrap Plus.

Provides specific information valid for the "Feeder Cycle" wrapping mode.

Explains how to activate the emergency stop button and restart the Masterwrap Plus machine.

Guides on loading film spools onto the film carriage for FR-FRD and FR types.

Details how to block the film edge at the pallet's corner after loading.

Provides general recommendations for performing machine maintenance.

Outlines maintenance tasks for components like machine, rubber roller, and braking disc at specific intervals.

Details maintenance for 20000 and 100000 cycles, including wear checks and gearmotor maintenance.

Illustrates lubrication points and methods for grease and silicone grease application.

Lists recommended mineral oils, greases, and synthetic oils for lubrication.

Lists displayed alarm messages, problem types, causes, and solutions.

Lists common alarm codes, problems, causes, and solutions for Ecowrap Plus.

Lists common alarm codes, problems, causes, and solutions for Masterwrap Plus.

Details common issues like carriage vibration, film release problems, and noise, with their causes and fixes.

Covers issues like poor drive force, unsynchronised stops, and sensor-related alarms with solutions.

Provides recommendations for replacing machine parts safely and with original parts.

Lists recommended spare parts for easy availability to avoid machine downtimes.

Outlines procedures for safely decommissioning and scrapping the machine and its components.

Details the warranty terms, coverage, exclusions, and conditions for the machine.

| Maximum pallet weight | 2000 kg |

|---|---|

| Film Width | 500 mm |

| Max Film Roll Diameter | 300 mm |

| Max Load Diameter | 1200 mm |

| Max Load Weight | 2000 kg |

| Film carriage | FRD |

| Machine Dimensions | 2800 mm x 1650 mm x 2400 mm |

Loading...

Loading...