Why is the film too loose during Robopac Stretch Wrapping Systems operation?

- BbauersarahAug 15, 2025

If the film is too loose during the wrapping operation, increase the braking effect of the clutched roller.

Why is the film too loose during Robopac Stretch Wrapping Systems operation?

If the film is too loose during the wrapping operation, increase the braking effect of the clutched roller.

Why is the film too tensed during Robopac Stretch Wrapping Systems operation?

If the film is too tensed during the wrapping operation, reduce the braking effect of the clutched roller.

What to do if wrapping begins too close to the product edge in Robopac Stretch Wrapping Systems?

If the wrapping begins too close to the product edge, increase the “head positioning” time.

What to do if wrapping begins too far from the product edge in Robopac Stretch Wrapping Systems?

If the wrapping begins too far from the product edge, decrease the “head positioning” time.

What to do if film overlaps too much on the product with Robopac Stretch Wrapping Systems?

If the film overlaps too much on the product, increase conveyors’ speed.

What to do if film overlaps too little on the product with Robopac Stretch Wrapping Systems?

If the film overlaps too little on the product, decrease conveyors’ speed.

What to do if wrapping terminates too close to the product edge in Robopac Stretch Wrapping Systems?

If the wrapping terminates too close to the product edge, decrease the “tail positioning” time.

What to do if wrapping terminates too far from the product edge in Robopac Stretch Wrapping Systems?

If the wrapping terminates too far from the product edge, increase the “tail positioning” time.

How to fix wrapping laps that are not compact in Robopac Stretch Wrapping Systems?

If the wrapping laps are not compact, check if the spool has been mounted correctly according to the film’s adhesive side.

Explains the manual's objective to provide operator instructions for safe use.

Details the machine's identification plate and its information.

Defines key terms used in the manual for clarity.

Outlines procedures for obtaining technical support and ordering spare parts.

Lists all documentation provided with the machine.

Provides guidance on navigating and utilizing the manual's content effectively.

Lists fundamental safety rules and attentiveness required for machine operation.

Safety guidelines for personnel involved in machine handling and installation processes.

Essential safety measures for the daily use and operation of the machine.

Highlights risks and prohibitions associated with foreseeable incorrect uses of the machine.

Discusses inherent risks that persist even after safety measures are applied.

Safety precautions related to adherence to regulations and proper maintenance.

Explains the meaning and placement of various safety and information signals on the machine.

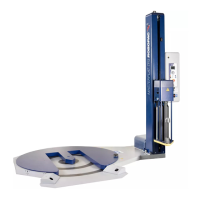

Provides an overview of the machine's function, capabilities, and available versions.

Details various wrapping cycles including Total, Head-Tail, Complete, and others.

Identifies and describes the various safety devices installed on the machine.

Explains the positioning and function of the machine's electrical components.

Details the placement and function of the pneumatic system components.

Lists optional accessories that can be added to the machine.

Lists key technical data, product sizes, dimensions, and installation environment requirements.

Provides essential guidelines for safely handling and loading the machine.

Describes how the machine is packed for transport, considering disassembly.

Details methods and considerations for transporting the machine.

Instructions for safely lifting and handling the machine using appropriate equipment.

Step-by-step guide for installing the machine.

Procedure for performing the standard assembly operations of the machine.

Instructions for installing the infeed and outfeed carriers.

General advice for making electrical and pneumatic connections.

Detailed steps for correctly connecting the pneumatic system.

Instructions for making the electrical connections to the machine's power supply.

General safety and procedural recommendations before performing adjustments.

Guide to adjusting the roller guides for product containment.

Instructions for adjusting the height position of the pressure units.

How to adjust the pressure applied by the pressure platens.

Procedure for adjusting the friction on the film spool carriage roller.

Guide to adjusting the pre-stretch tension of the film.

General advice and precautions for operating the machine correctly and safely.

Detailed description of the machine's main controls and their functions.

Instructions on how to navigate and interact with the machine's control panel.

Description of the main operator panel screen and its parameters.

Guide to changing operator profiles and machine passwords for access control.

Procedure to restore the machine to its default password settings.

How to access and modify general machine parameters.

Explains how to access and adjust software settings like display brightness and version info.

Instructions for setting the machine's date and time.

Details the manual controls on the panel for individual machine part operation.

Overview of how settings can be modified through written input or progressive regulation.

How to input and confirm text or numerical values using the keypad.

How to adjust values using increment/decrement buttons and graphic bars.

Procedure for copying recipes between the terminal and an SD card or PC.

Guide to setting specific parameters that define a wrapping cycle or recipe.

How to reset the wrapping cycle to resume or restart operations.

Describes the different states the machine can be in for operation or maintenance.

Safety procedure for disconnecting power for maintenance.

Condition where the machine has power for interventions.

State indicating the machine is prepared to start a wrapping cycle.

Steps to perform before starting machine operations, including adjustments.

Steps required to initiate the machine's wrapping process.

Procedure to ensure the rotating ring is correctly aligned for operation.

Detailed instructions for loading the film spool onto the machine.

Steps to insert the film into the cutting clamp mechanism.

The final steps to start a wrapping cycle.

Overview of different conditions that cause the machine to stop or require starting.

How to perform a brief, voluntary stop of the machine.

Behavior and restart procedure following an unexpected power outage.

Procedure for stopping the machine at the end of a work shift or period.

How to use the emergency stop button and restart the machine.

Procedure when the machine stops due to a light curtain being tripped.

General safety and procedural guidelines for performing maintenance.

Schedule of recommended maintenance tasks based on operating hours.

Steps for draining accumulated condensate from the pneumatic system.

Instructions for disassembling, cleaning, and reassembling the filter.

How to manually move the rotating ring for specific maintenance tasks.

Procedure for adjusting the position of the rotating ring's retaining wheels.

Guide to adjusting the tension and alignment of the conveyor belts.

General cleaning procedures for the machine's exterior and specific components.

Common operational problems and their recommended solutions.

Lists displayed alarm messages, their causes, and corrective actions.

Guidelines and safety precautions for replacing machine parts.

Step-by-step instructions for safely replacing the film cutting blade.

A list of critical spare parts recommended for availability to prevent downtime.

Procedures and considerations for environmentally responsible machine disposal and scrapping.

Details the terms and conditions of the manufacturer's warranty for the machine.

Technical diagram illustrating the pneumatic circuit for the 250 coil version.

Technical diagram illustrating the pneumatic circuit for the 500 coil version.

Declaration confirming the machine's compliance with relevant CE directives.

| Brand | Robopac |

|---|---|

| Model | ORBIT 16 |

| Category | Stretch Wrapping Systems |

| Language | English |

Loading...

Loading...