Do you have a question about the Robopac Masterplat PLUS TP3 PGS and is the answer not in the manual?

Summarizes safety-related pictograms indicating danger, such as electric shock, moving parts, and high temperatures.

Summarizes safety pictograms indicating prohibitions, such as no smoking, no naked flames, and do not insert hands.

Summarizes safety pictograms indicating obligations, such as wearing protective gloves, goggles, and safety shoes.

Provides general warnings about reading instructions, understanding risks, and the importance of operator caution.

Details safety precautions for loading, unloading, transport, storage, and installation of the machine.

Outlines safety rules for operating the machine, including using safety devices and maintaining perimeter areas.

Addresses potential misuse of the machine and the responsibilities of employers regarding operator training.

Defines foreseeable misuse scenarios and lists prohibited actions to prevent damage or injury.

Specifies employer duties regarding operator training, skills, and documentation for safe machine operation.

Highlights residual risks inherent in machine operation, such as slipping, impact, and shearing.

Provides safety guidelines for performing adjustments, maintenance, and repairs on the machine.

Details safety requirements for the electrical equipment, including ambient temperature and humidity.

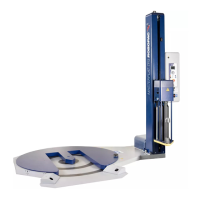

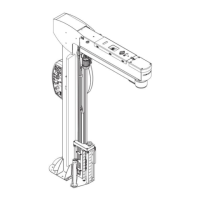

Details the different machine models available and their specific features, including spool carriage types.

Explains the step-by-step process of the machine's operation cycle, from loading to unloading.

Identifies and describes the function of various safety devices installed on the machine.

Details the various electrical components and devices that control the machine's operations.

Presents the dimensional specifications and technical data for the Masterplat PLUS machine models.

Provides detailed dimensions for the Masterplat PLUS FRD machine and associated pallet sizes.

Provides guidance on safe handling and loading procedures, emphasizing understanding instructions and safety conditions.

Details safe transport methods and the importance of adequately anchoring the machine during transit.

Explains how to safely move and lift the machine using a forklift truck, emphasizing qualified personnel.

Provides step-by-step instructions for installing the machine, emphasizing safety and proper positioning.

Outlines the steps for correctly connecting the machine to the power supply, including voltage and earthing.

Explains how to adjust the film stretch on FRD type spool carriages using the lever and handwheel.

Provides recommendations for operating the machine safely and efficiently, including daily checks and safety devices.

Details the functions of various controls, including emergency stop, user interface, and main disconnecting switch.

Details the different wrapping cycle options: double, single, and double with feeder.

Details the procedure for safely switching the machine on and off, including special notes for certain models.

Explains how to set cycle parameters by choosing and editing recipes using the jog control.

Describes the different wrapping cycles: single, double, and double with feeder.

Outlines the steps for starting, stopping, suspending, and restarting the wrapping cycle.

Details the procedure for loading film spools onto the spool carriage, including path and brake settings.

Provides crucial recommendations for maintenance, emphasizing safety, PPE, and contacting authorized service.

Presents a table detailing periodical maintenance tasks, components, and their recommended frequencies.

Lists common alarm codes, their problems, causes, and recommended solutions for troubleshooting.

Provides guidelines for replacing machine parts, emphasizing safety, original parts, and contacting service.

| Brand | Robopac |

|---|---|

| Model | Masterplat PLUS TP3 PGS |

| Category | Stretch Wrapping Systems |

| Language | English |