Do you have a question about the Robopac Masterplat PLUS LP PGS and is the answer not in the manual?

Explains the manual's aim to provide operating instructions for safety and risk minimization.

Details the information found on the machine's identification plate.

Defines recurring terms used in the manual for clarity.

Summarizes safety pictograms that indicate danger.

Summarizes safety pictograms indicating prohibitions.

Summarizes safety pictograms indicating obligations.

Provides contact for assistance and lists attached documentation.

Guides users on how to navigate and understand the manual's structure.

General warnings about reading instructions, understanding risks, and operator responsibility.

Safety precautions for loading, unloading, transport, and installation.

Safety guidelines for operating the machine, including PPE and safety devices.

Details improper uses of the machine and associated risks.

Highlights specific residual risks of the machine and necessary precautions.

Safety precautions before performing adjustments or maintenance operations.

Safety requirements for the electrical equipment and operating environment.

Explains the meaning and placement of various safety and information signs.

Illustrates the required working and safety perimeter areas around the machine.

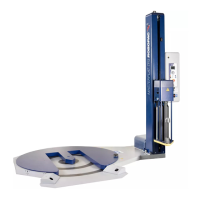

Provides a general overview of the machine's function and design.

Details the different machine models and their specific features.

Explains the step-by-step process of a typical wrapping cycle.

Identifies and describes the various safety devices installed on the machine.

Lists and explains the function of electrical components on the machine.

Explains the features and functionality of the remote control software.

Identifies and describes the pneumatic components used in the machine.

Details optional accessories available to enhance machine performance.

Presents dimensional specifications and technical data for Masterplat PLUS models.

Provides dimensions for Masterplat PLUS FRD machines and pallets.

Provides dimensions for Masterplat PLUS PGS machines and pallets.

Provides dimensions for Masterplat PLUS PGS USA machines and pallets.

Lists key technical specifications for the machines.

Details the technical specifications of the presser unit.

Lists spool dimensions and characteristics for FRD and PGS models.

Presents technical data for Masterplat PLUS LP FRD and PGS models.

Provides dimensions for Masterplat PLUS LP FRD machines and pallets.

Provides dimensions for Masterplat PLUS LP PGS machines and pallets.

Provides dimensions for Masterplat PLUS LP PGS USA machines and pallets.

Lists key technical specifications for Masterplat PLUS LP models.

Details the technical specifications of the presser unit for LP models.

Lists spool dimensions and characteristics for LP FRD/PGS models.

Presents technical data for Masterplat PLUS TP3 FRD and PGS models.

Provides dimensions for Masterplat PLUS TP3 FRD machines and pallets.

Provides dimensions for Masterplat PLUS TP3 PGS machines and pallets.

Lists key technical specifications for Masterplat PLUS TP3 models.

Details the technical specifications of the presser unit for TP3 models.

Lists spool dimensions and characteristics for TP3 FRD/PGS models.

Details the airborne noise levels of the machine at the operator's position.

Lists prerequisites for the machine's installation environment.

General recommendations for safe handling and loading procedures.

Information on how the machine is packed and procedures for unpacking.

Guidelines for safely transporting and handling the machine.

Instructions for moving and lifting the machine using forklift trucks.

Step-by-step instructions for installing the machine.

Details the procedure for assembling the electric box.

Instructions for assembling the slide shaft.

Further instructions for assembling the slide shaft.

Instructions for assembling the loading/unloading ramp.

Steps to modify the loading direction of the ramp.

Instructions for assembling the optional pneumatic presser.

Procedures for securely fixing the machine to the floor.

Instructions for underground installation of the machine.

General recommendations for making electrical and pneumatic connections.

Step-by-step guide for making pneumatic connections.

Instructions for connecting the machine's electrical power supply.

General recommendations before performing any adjustments.

How to adjust film stretch for FRD type spool carriages.

Procedure for adjusting film stretch on FRD type spool carriages.

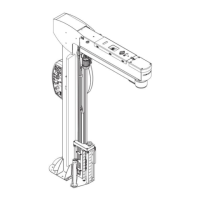

Procedure for replacing pre-stretch gears on PGS type spool carriages.

Instructions for adjusting film tension on FRD for mesh type spool carriages.

How to adjust the spool carriage lifting chain.

Procedure for adjusting the rotary table chain.

How to adjust the rotary table chain for TP models.

Instructions for adjusting the rotary table gear wheels.

How to adjust the table guide wheels.

General recommendations for operating and using the machine safely.

Explains the function of each control on the machine's interface.

Details the machine's user interface, navigation, and display elements.

Overview of the main menu and its available options.

How to select and initiate different wrapping cycles.

How to view and adjust the table rotation speed.

How to view and adjust carriage speed, upstroke, and downstroke speeds.

How to set wrapping end delay and pallet height.

Explains the manual control functions for machine movements.

How to adjust film tensioning for PGS versions.

Explains other functions like presser control and recipe data.

Details the machine's settings, including cycle counter and panel lock.

How to manage and select machine recipes/programmes.

How to operate the machine in manual cycle mode.

How to use and operate the ECO cycle.

Explains miscellaneous functions and operations.

Procedures for switching the machine on/off and setting cycle parameters.

How to perform single, double, and feeder wrapping cycles.

Specific information for the feeder cycle wrapping mode.

How to adjust the presser height and pneumatic cylinder.

Instructions for loading film spools onto the carriage.

General recommendations and safety precautions for maintenance.

Table outlining periodical maintenance tasks and their frequency.

Diagrams showing lubrication points and recommended intervals.

Lists recommended lubricants for different machine components.

Instructions for draining condensate from the pneumatic system.

How to clean the air filter.

Procedures for cleaning the machine and its components.

Lists common alarm messages, their causes, and solutions.

General recommendations and safety for replacing machine parts.

Step-by-step guide to replacing rotary table wheels.

Instructions for replacing rotary table rollers.

How to replace the guiding rollers.

Instructions for replacing rotary table gear wheels.

Lists frequently wearing spare parts recommended to keep in stock.

Procedures for safely decommissioning and scrapping the machine.

Details the warranty terms and conditions for the machine.

Provides a pneumatic diagram for the presser unit.

| Model | Masterplat PLUS LP PGS |

|---|---|

| Max Load Weight | 2000 kg |

| Turntable Diameter | 1650 mm |

| Film Width | 500 mm |

| Max Wrapping Height | 2200 mm |

| Control System | PLC with touch screen |

| Pre-stretch | Up to 250% |

| Max Wrapping Speed | 12 rpm |

| Max Pallet Height | 2200 mm |

| Power Supply | 230 V, 50/60 Hz |

| Film Carriage Type | PGS (Power Pre-Stretch) Carriage |

| Max Film Force | Adjustable |