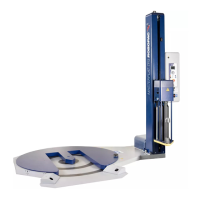

ORBIT 16

H) Driving axle (Optional)

Additional sheets to that already present to support short products (Not shown).

I) Guide (Optional)

adjust the width for product containment.

) Reel support unit with jumper

Composed of a fast loading spool carriage spindle, two idler rollers that adjust the wrapping tension and

a coating recovery device.

The unit is accessed through mobile protection (K).

M) Product inlet and outlet MUTING light curtains (Optional)

N) Barrier controls

Contains the controls necessary for resetting the machine after one of the light curtains tripped.

Danger - Warning

his machine is normally installed in workshops or industrial environments protected from the atmospheri

agents.

Use of this machine in explosive environments or when exposed to the elements is strictly forbidden.

During the operating stages just one operator is necessary to perform the infeed, cycle start and wrapped

product outfeed operations.

According to the different operating requirements, this machine can be supplied in different models and

configurations.

Machine Coil

Orbit 16 250 / 500

3.2. DESCRIPTION OF THE

OPERATION CYCLE

Wrapping cycles performable

Product wrapping can be:

1) "Total" wrapping

The product is completely spiral wrapped

with a series of extra revolutions on head

and tail.

2) "Head - tail" wrapping

the product is only wrapped on head and

tail.

3) "Complete" wrapping and "central bands"

The product is completely wrapped in a spiral, with a series of additional loops at the head, at the tail

and with a series of reinforcement strappings spaced by a programmable time.

4) "Head-tail" and "central belts" wrapping

The product head and tail are wrapped with a series of reinforcing bands spaced by a programmable

time.

5) “Head and additional bands” winding

The head of the product is wrapped and a series of additional reinforcement strappings are made (their

number and the distance between them can be set from the relevant parameters).

6) "By-pass" cycle

the product goes through the machine without being wrapped.

3.2.1."TOTAL" WRAPPING

With the product on the feed conveyor, press the “Start” button on the control panel to start the work cycle.

Loading...

Loading...