SMC™ Flex Quick Start 3

• The controller contains ESD- (electrostatic discharge) sensitive parts and assemblies. Static control precautions

are required when installing, testing, servicing, or repairing the assembly. Component damage may result if

ESD control procedures are not followed. If you are not familiar with static control procedures, refer to

applicable ESD protection handbooks.

• Stopping modes are not intended to be u

sed

as an emergency stop. The user is responsible for determining

which stopping mode is best suited to the application. Refer to the applicable standards for emergency stop

requirements.

• Pump Stopping may cause motor heating depending on the me

chanical dynamics of the pumping system.

Therefore, select the lowest stopping time setting that will satisfactorily stop the pump.

• Slow Speed running is not intend

ed fo

r continuous operation due to reduced motor cooling.

• The fan jumpers have been factory installed for 110/120V AC input. Refer to page 9 for 220/240V AC fan

wiring (5…480 A devices only).

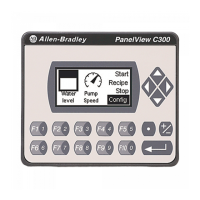

• Two peripheral devices can be connected to the DPI port. The maximum output

current through the DPI port

is

280 mA.

• When installing or inspecting protective modules, make sure

that th

e controller has been disconnected from the

power source. The protective module should be inspected periodically for damage or discoloration. Replace if

necessary.

• An incorrectly applied or installed contro

ller can damage components or reduce product life. Wiring or

application errors such as under sizing the motor, over sizing the controller, incorrect or inadequate AC supply,

excessive ambient temperatures, or power quality may result in malfunction of the system.

• The Motor Overload parameter must be

programmed by the installer to prov

ide proper protection. Overload

configuration must be properly coordinated with the motor.

• This product has been designed and tested as Class A equipment for EMC compatibility. Use of the product in

domestic environments may cause radio interference, in which case, the installer may need to employ

additional mitigation methods.

• Disconnect the controller from the mot

or before measuring insulation resistance (IR) of the mot

or windings.

Voltages used for insulation resistance testing can cause SCR failure. Do not make any measurements on the

controller with an Insulation Resistance (IR or Megger) tester.

NOTICE

Loading...

Loading...