Issue 3 Original Version Sept 2020

- 10 -

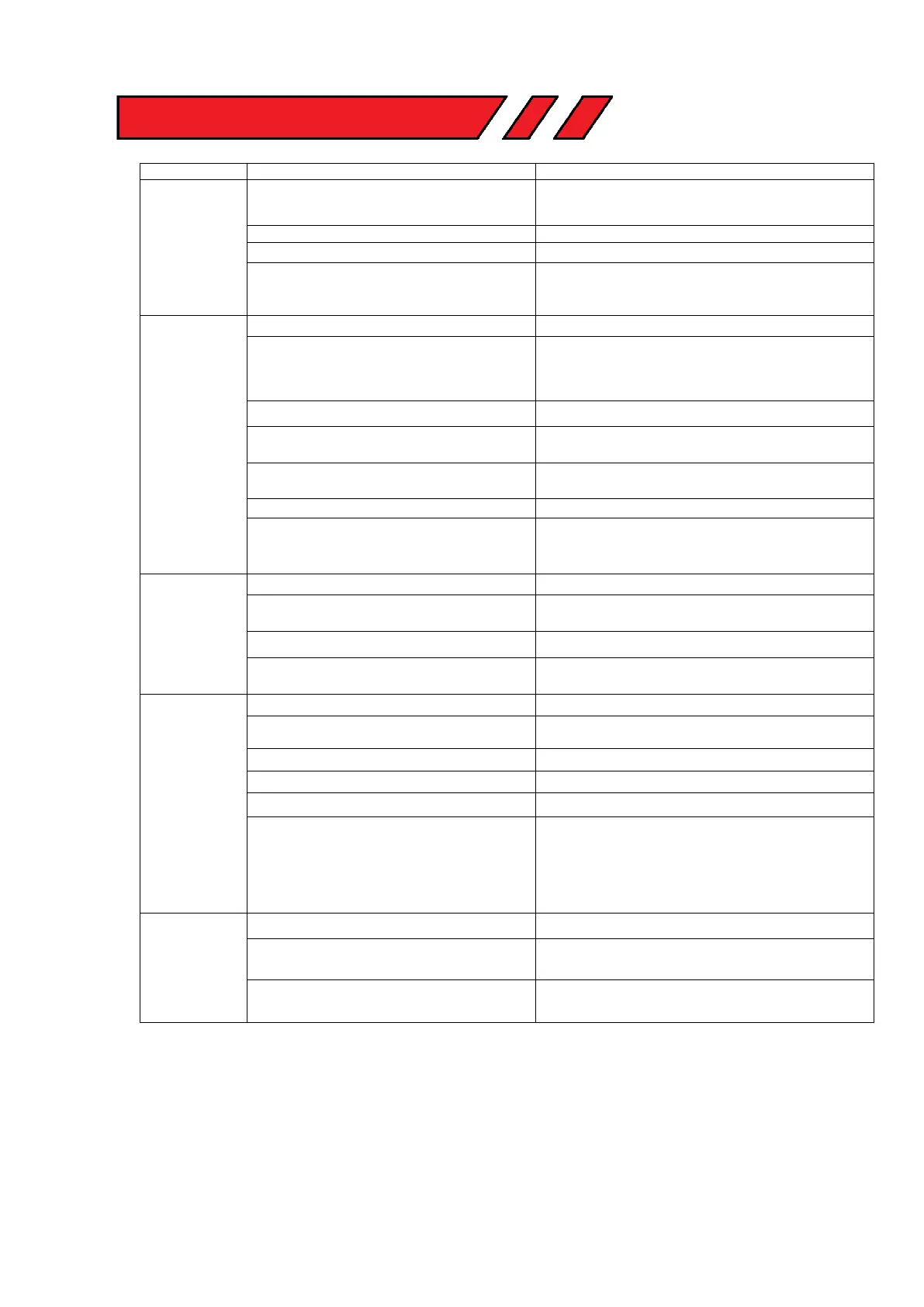

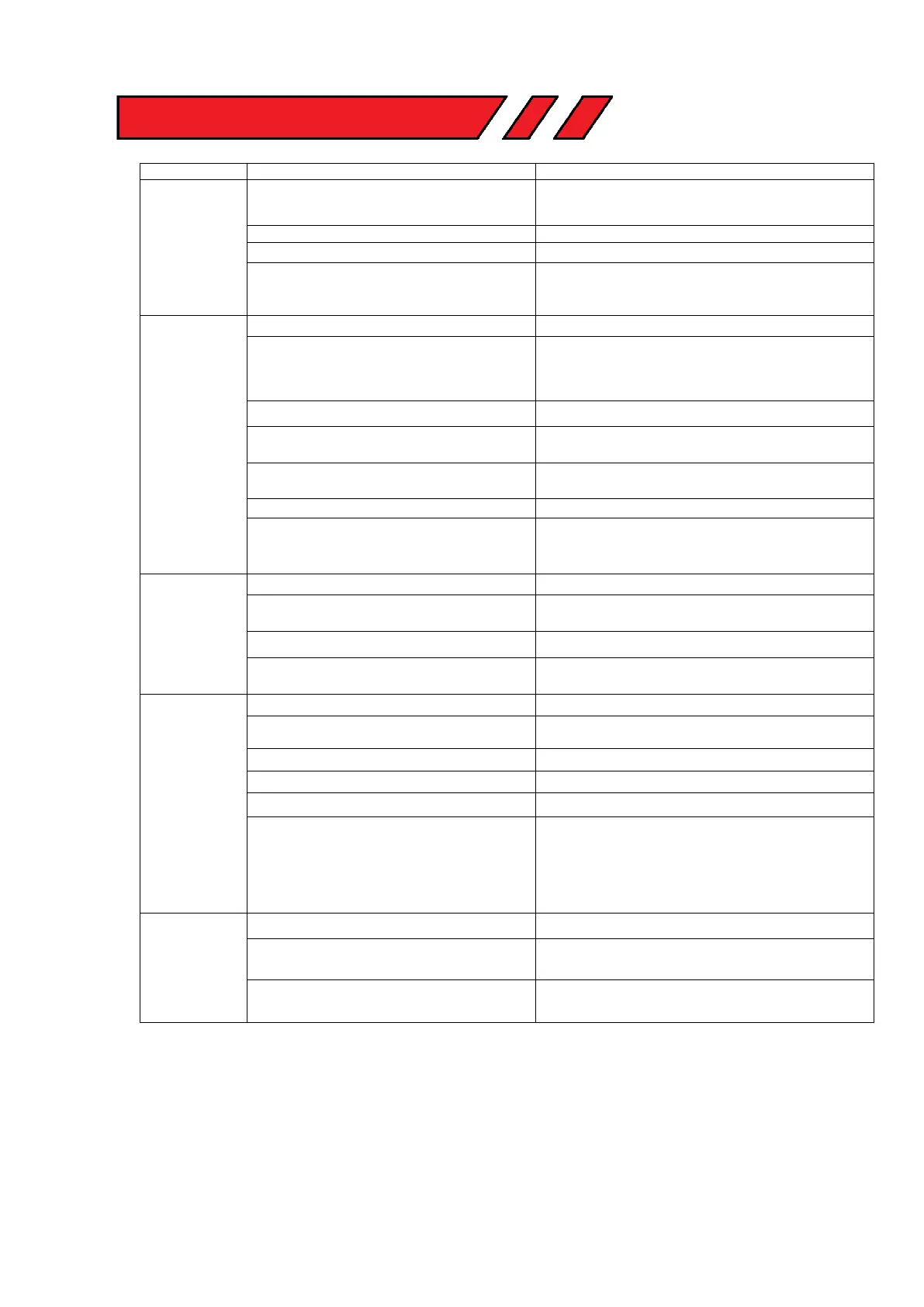

10) REMEDIES FOR HOLE MAKING PROBLEMS

1) Magnetic base

won’t hold

effectively

Material being cut may be too thin for efficient

holding.

Attach an additional piece of metal under work-piece where

magnet will be located, or mechanically clamp magnetic base

to work-piece.

Swarf or dirt under magnet.

Irregularity on magnet contact or work-piece.

Use extreme care; file any imperfections flush to surface.

Insufficient current going to magnet during drilling

cycles.

Confirm power supply and output from control unit, check

supply cable.

2) Cutter skips

out of centre-

punch mark at

initiation of cut

Magnetic base is not holding effectively.

See causes and remedies above.

Worn arbor bushing and/or ejector collar.

Replace! Only a few thousandths wear permissible. New arbor

bushing is needed.

Light pressure only is needed until a groove is cut. The groove

then serves as a stabiliser.

Too much feed pressure at start of cut.

Replace or re-sharpen. Sharpening service is available.

Cutter is dull, worn, chipped or incorrectly

sharpened.

Improve centre-punch and/or replace worn parts

Poor centre-punch mark; weak pilot spring; pilot not

centred in centre-punch mark.

Worn or bent pilot, worn pilot hole.

Loose bolts on motor bushing support bracket, main

casting or loose gib adjusting set screws.

3) Excessive

drilling pressure

required

Incorrectly re-sharpened, worn or chipped cutter.

Coming down on swarf lying on surface of work-

piece.

Take care not to start a cut on swarf.

Gibs out of adjustment or lack of lubrication.

Adjust setscrews, and lubricate.

Swarf accumulated (packed) inside cutter.

Steel swarf or dirt under cutter.

Remove cutter, clean part thoroughly and replace.

Incorrectly re-sharpened or worn cutter.

Always have a new cutter on hand to refer to for correct tooth

geometry, together with instruction sheet.

See causes and remedies (2).

Gib Strip need adjustment.

Cutter not attached tightly to arbor.

Insufficient use of cutting oil or unsuitable type of oil.

Inject oil of light viscosity into the coolant-inducing ring and

check that oil is being metered into cutter when pilot is

depressed. If not, check pilot groove and arbor internally for

dirt or apply oil externally. (Even a small amount of oil is very

effective).

See cause and remedy above

Incorrectly re-sharpened cutter.

Do not use. Refer to instructions and a new cutter for proper

tooth geometry.

Exercise, insufficient or spasmodic cutting pressure.

Use sufficient steady pressure to slow the drill down. This will

result in optimum cutting speed and chip load.

Loading...

Loading...