34

• Always keep all bolts and nuts tight. Check

periodically.

• Always raise lift when cleaning oor area.

• Always keep lift clean. Keep bottom weldment

dry and free from corrosives such as salt and

cleaning uids.

• Daily: Inspect rubber blocks for damage or

excessive wear. Replace as required with

genuine Rotary parts.

• Daily: With a representative vehicle on the lift,

check the lowering speed (not to exceed 0.15m/s)

• Weekly: Inspect all lift parts for signs of damage

due to overloading and rough handling.

• Monthly: Carry out a function test with and

without load.

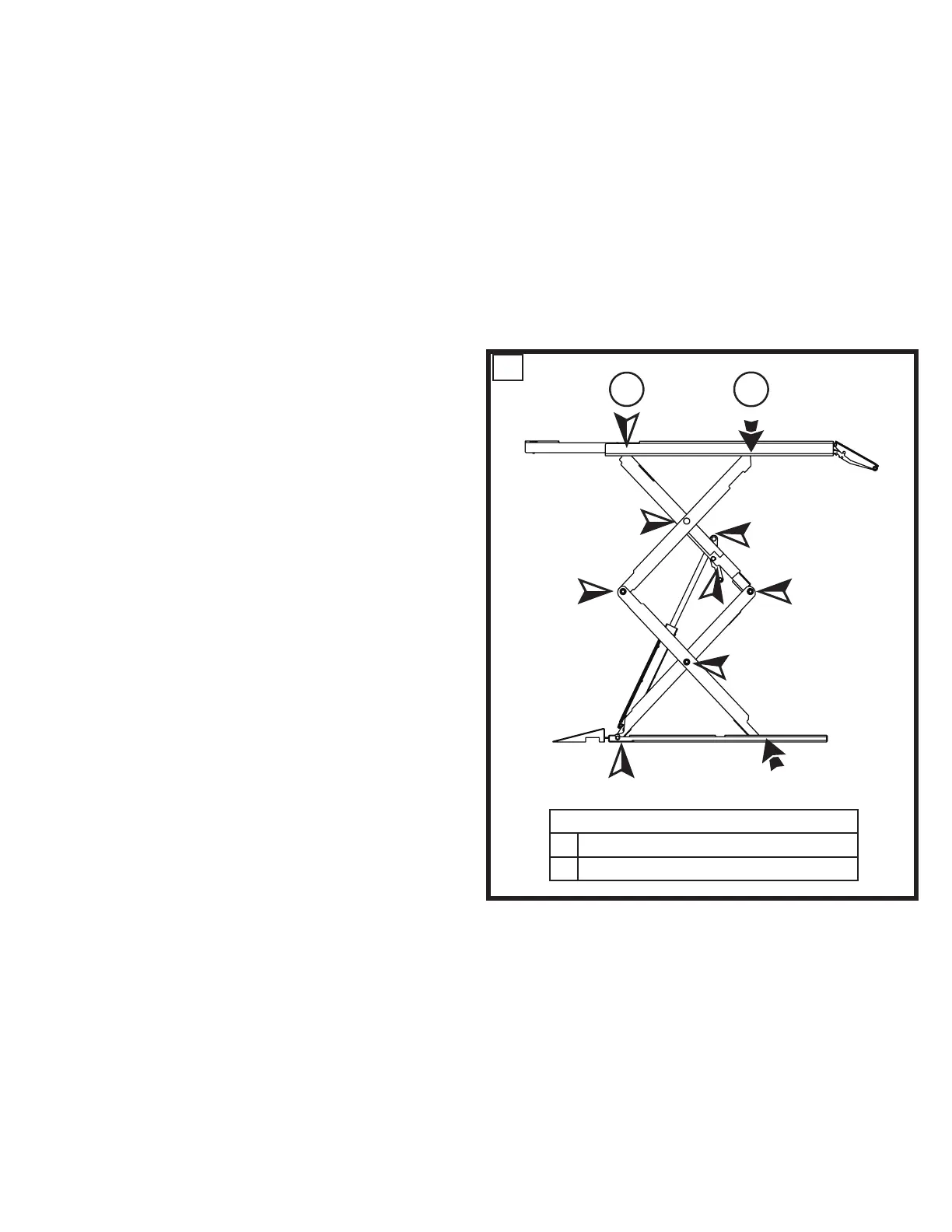

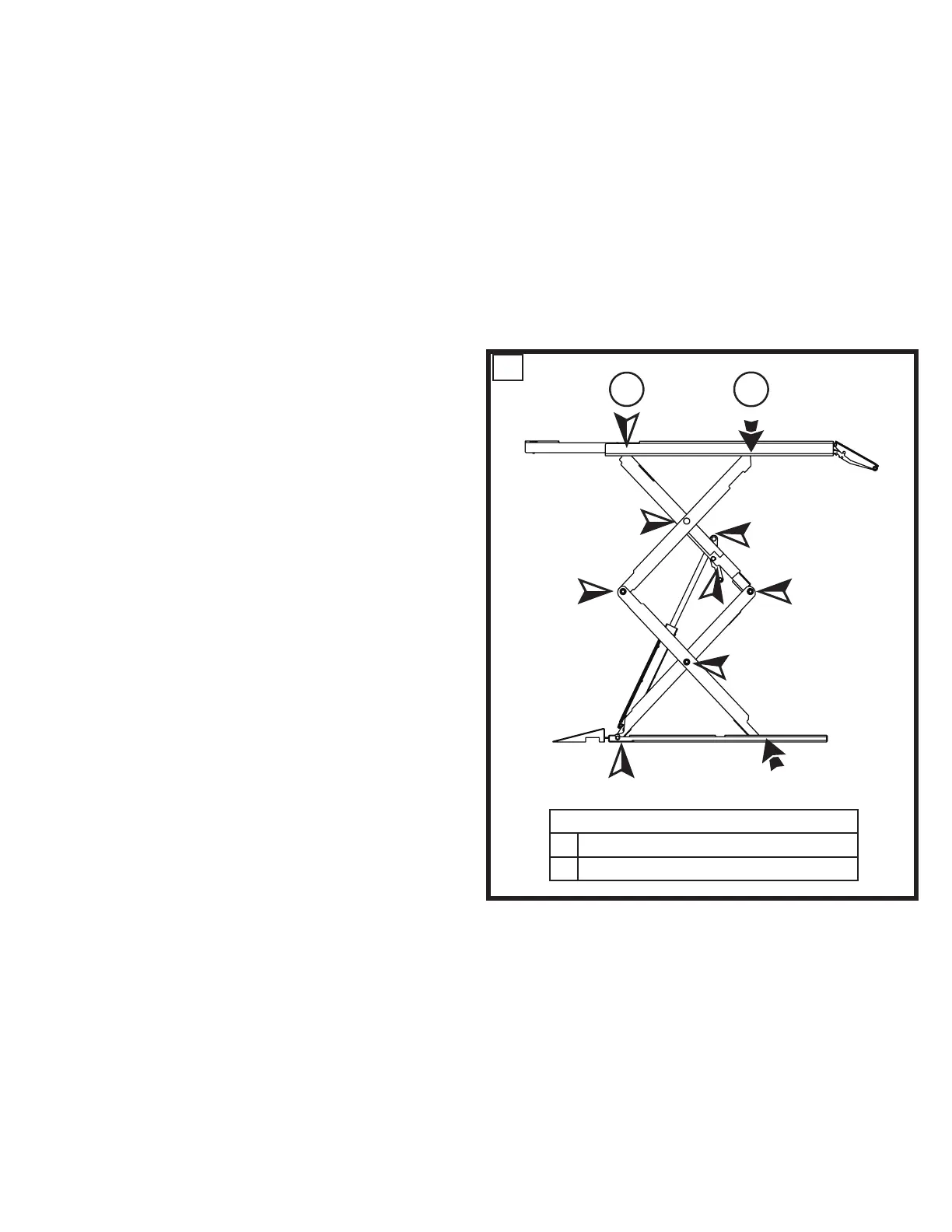

• Monthly: Lightly grease sliding surfaces(g

14 Item 2) and top cylinder clevis pin with all

purpose grease.

• Monthly: Check level of platforms, rebleed air

from cylinders if needed(pressing the "Override

Up" button on the printed circuit board located

in the cabinet and hold for approximately 40

seconds).

• Monthly: Inspecting the sliding blocks(g14

item2) and sliding bearing (g 14 item 1) ,perform

a visual check for wear.

• Semi-Annually: Check uid level of lift power unit

while lift is fully lowered. Rell if required per ll

line on tank. If uid is required, inspect all hoses

and and cylinder for leakage (Visual inspection)

.with lift loaded,stop the lift at midpoint of travel

and observe for drifting down and hydraulic leaks.

Repair or replace as required.

• Semi-Annually: Check anchor bolts to ensure

the torque according to the supplier of the anchor

bolts.

• Annual: Inspect electrical cables for

damage(visual inspection).

1

2

• Annual:Check that control buttons and switches

function properly.

• If lift stops short of full rise or chatters, check uid

level and purge both cylinders per lift installation

instructions.

• Replace all CAUTION, WARNING, or SAFETY

related decals on the lift if unable to read or

missing. Reorder labels from Rotary Lift.

• Complete maintenance report and inspection

report from safety inspection ( → Annex).

Fig. 14 Detail

1 Sliding bearings

2 Sliding blocks

14

Loading...

Loading...