5

Concrete and Anchoring:

If you are installing a seismic lift, consult with your

structural engineer and manufacturer’s representative for

concrete and anchoring requirements (varies by location).

Fig. 4 and the below table apply to non-seismic lifts only.

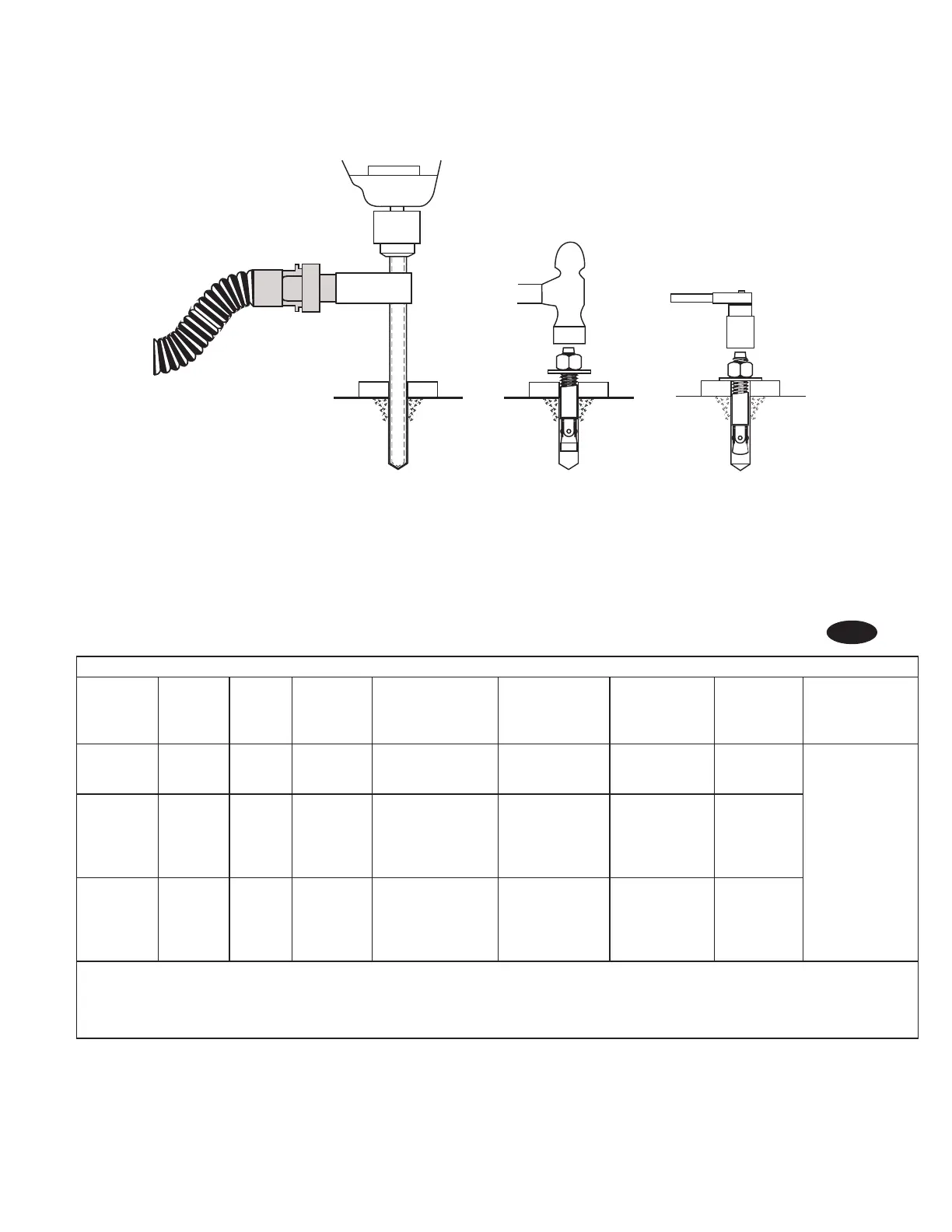

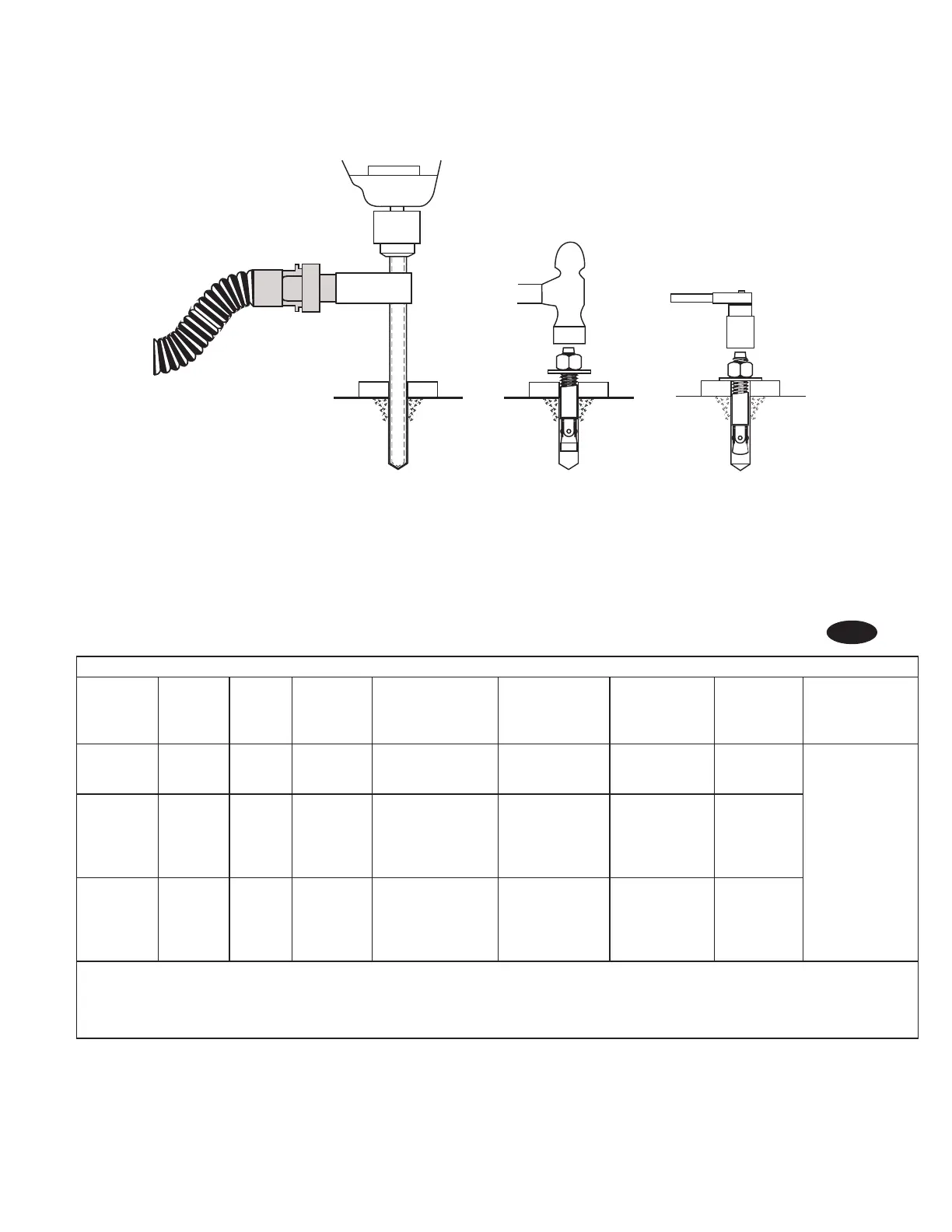

Fig. 4

7-10K 2-Post Lift Anchor Installation Reference Guide

Anchor: Min

Concrete

Thickness

Min Edge

Distance

Min Anchor

Embedment

Installation Anchor

Torque ft-lbs

Min Concrete PSI

Strength - For All

Standards

Concrete pad

Size If Concrete

Does Not Meet

Requirements

Maintenance

Torque

Values

SEISMIC

Hilti Kwik

Bolt III (3/4" x

5-1/2")

4-1/4"

(108mm)

3-3/8"

(86mm)

3-1/4" (83mm) 110

(149Nm)

3000

(20684 kPa)

4'x4'x6"

(1219 x 1219 x

152mm)

65 ft-lbs

(88Nm)

Varies by

location consult

with your

structural engineer

and manufacturer’s

representative.

Hilti HY200

(with HAS

threaded rod)

6-7/16"

(164mm)

1-3/4"

(45mm)

4-1/2"

(115mm)

100 (149Nm) / less

than 3-3/4" (95mm)

edge distance use

Torque Value of 30

ft-lbs (41Nm)

3000

(20684 kPa)

4'x4'x6"

(1219 x 1219 x

152mm)

N/A

Hilti HY200

(with HAS

threaded rod)

5-1/4"

(134mm)

3" (77mm) 3-1/2" (89mm) 100 (149Nm) / less

than 3-3/4" (95mm)

edge distance use

Torque Value of 30

ft-lbs (41Nm)

3000

(20684 kPa)

4'x4'x6"

(1219 x 1219 x

152mm)

N/A

*The supplied concrete fasteners meet the criteria of the American National Standard

“Automotive Lifts - Safety Requirements for Construction, Testing, and Validation” ANSI/ALI ALCTV-2011,

and the lift owner is responsible for all charges related to any additional anchoring requirements as

specified by local codes. Contact customer service for further information at: 800.640.5438

Run nut down just below impact

section of bolt. Drive anchor

into hole until nut and washer

contact base.

Drill holes using 3/4” carbide

tipped masonry drill bit per

ANSI B212.15-1994 (R2000).

Construction dust collected

per OSHA 29 CFR 1926.1153.

Tighten nut with Torque

wrench to 110 ft.-lbs.

(149 Nm).

Loading...

Loading...