9

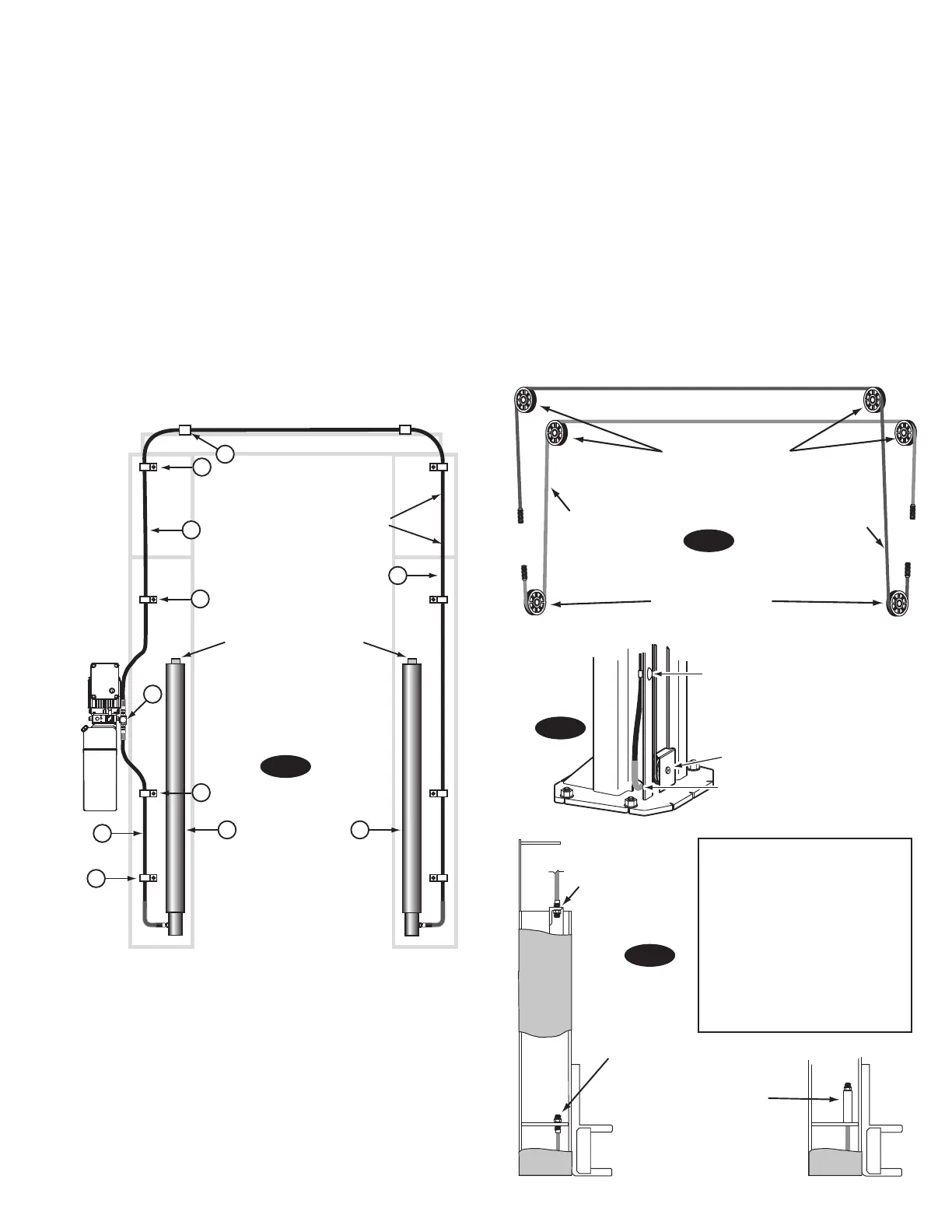

Adapter & Hose Installation (see Fig. 12)

1. Install Pc. (2) with metal hose clamps, on power unit

column side connecting it to the cylinder (1) first.

2. Install Pc. (3) with plastic hose clamps starting at

opposite column cylinder (1) and working toward

the power unit column. All excess hose should be at

bends & inside overhead assembly. DO NOT try to

use optional column extension mounting holes, Fig. 2a,

when attaching hose clamps. They will NOT work. Use

lower set of holes.

3. Install Pc. (4) into power unit.

4. Connect Pc. (2) & Pc. (3) to Tee (4).

NOTE: Route Power Unit hose inside columns using slots

provided at column base, Fig. 14. Route Overhead Hose in

column channel on outside of column, Fig. 14. Overhead

hose goes over top end of overhead assembly, Fig. 12 &

Fig. 16a & Fig. 16b.

1

2

6

4

6

FRONT

Hose runs down

approach side to

cylinder on left column.

Cylinder bleeders

Torque values

15 ft-lbs. (20Nm) Min.

20 ft-lbs. (27Nm) Max.

*

*

*

*

**

##

# #

6

5

3

3

5

1

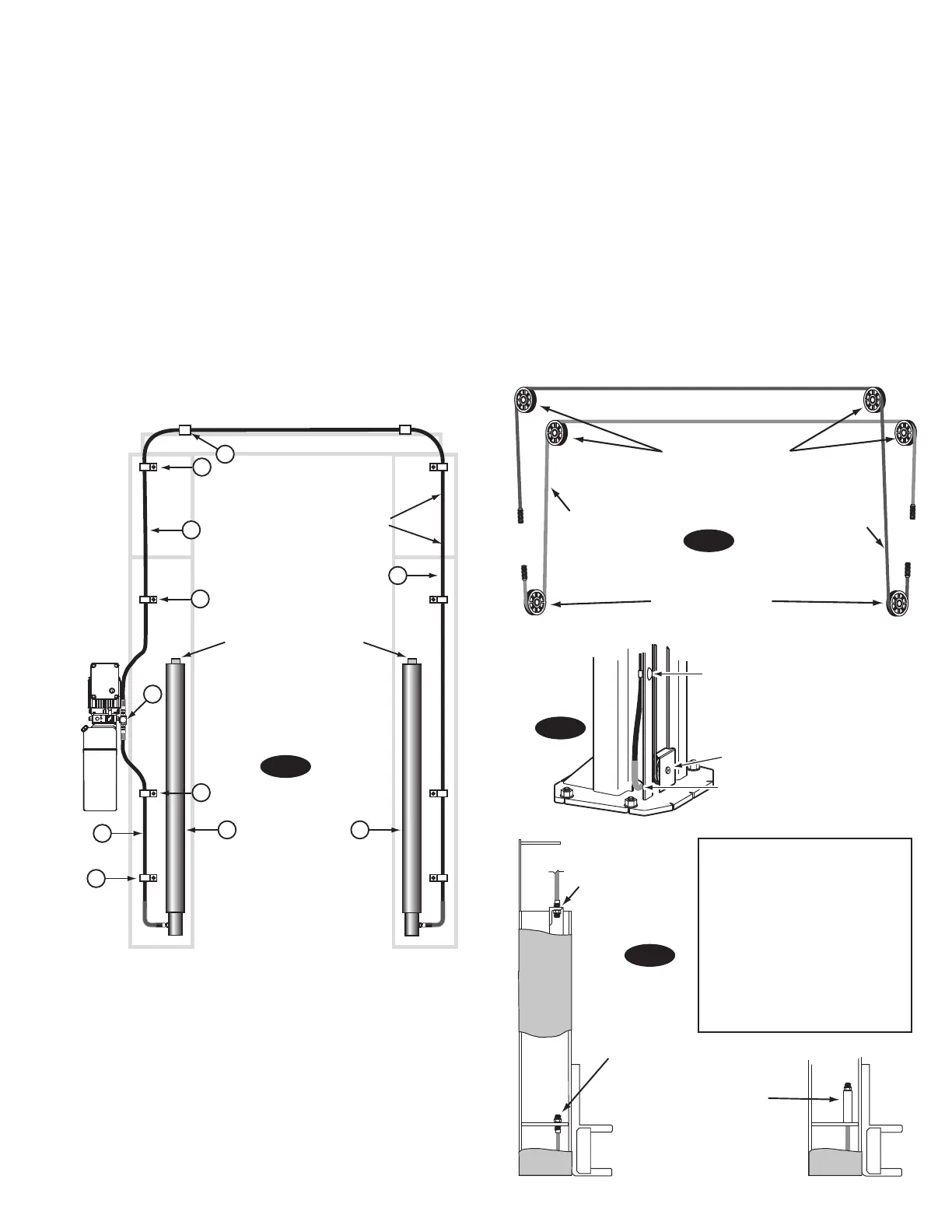

11. Equalizing Cables

A) Refer to Fig. 13 for the general cable arrangement.

First, run a cable end up through the small hole in the

lower tie-off plate. Fig. 15.

B) Push the cable up until the stud is out of the carriage

top opening.

C) Run a nylon insert locknut onto the cable stud so 1/2”

(13mm) of the stud extends out of the locknut.

D) Pull the cable back down, Fig. 15.

E) Run cable around the lower sheave, then up and

around overhead sheave and across and down to the

opposite carriage, Fig. 13. Install sheave cover, Fig. 14.

F) Fasten the cable end to the carriage upper tie-off

bracket, Fig. 15. Tighten the locknut enough to apply

light tension to the cable.

G) Repeat procedure for the second cable. Complete lift

assembly. Adjust the tension of both cables during the

final adjustments in Paragraph 20.

ITEM QTY. DESCRIPTION

1 2 Hydraulic Cylinder

2 1 Power Unit Hose

3 1 Overhead Hose

4 1 Branch Tee

5 2 Metal Hose Clips

*6 3/8-16NC x 3/4” lg. Carriage Bolts

*6 3/8”-16NC Flanged Locknuts

6 8 Plastic Hose Clips

#4 3/8-16NC x 3/4” lg. Flanged HHCS

#4 3/8”-16NC Flanged Locknuts

Fig. 12

Upper Cable Tie Off

& 5/8" Nylon Insert

Locknut

Lower Cable Tie Off

& 5/8" Nylon Insert

Locknut

3/4"(19mm)

SCHEDULE 40

steel pipe spacer

for Narrow Bay

and/or Low Ceiling

The lengths required for pipe spacers

are as follows (NB = Narrow Bay and

LC = Low Ceiling):

SPOA7NB or LC= 8" (203mm)

SPOA7NB & LC = 16" (406mm)

SPO10LC or SPOA10LC = 8" (203mm)

SPOA10NB = 6” (153mm)

SPOA10NB & LC = 14” (356mm)

1st Cable

2nd Cable

Upper Sheaves

Lower Sheaves

Fig. 13

Fig. 14

Fig. 15

Hose Slot and Hose

Attach hose to column

using 3/8"-16NC x 3/4"

Carriage Bolts, Flanged

Locknuts, and Hose Clips

Sheave Cover

Loading...

Loading...