36

COMPILER TECO/ATI ENDORSEDDATE

23.06.2003

REG. CODE

1-5302-602

MODEL N°

50884

DATE OF ISSUE

06-03

REVISION 00

77

78

79

80

XIII

1,75 ÷ 2,25 mm

4 kgm (Nm 39,2)

0,15 mm

ENGINE ASSEMBLY

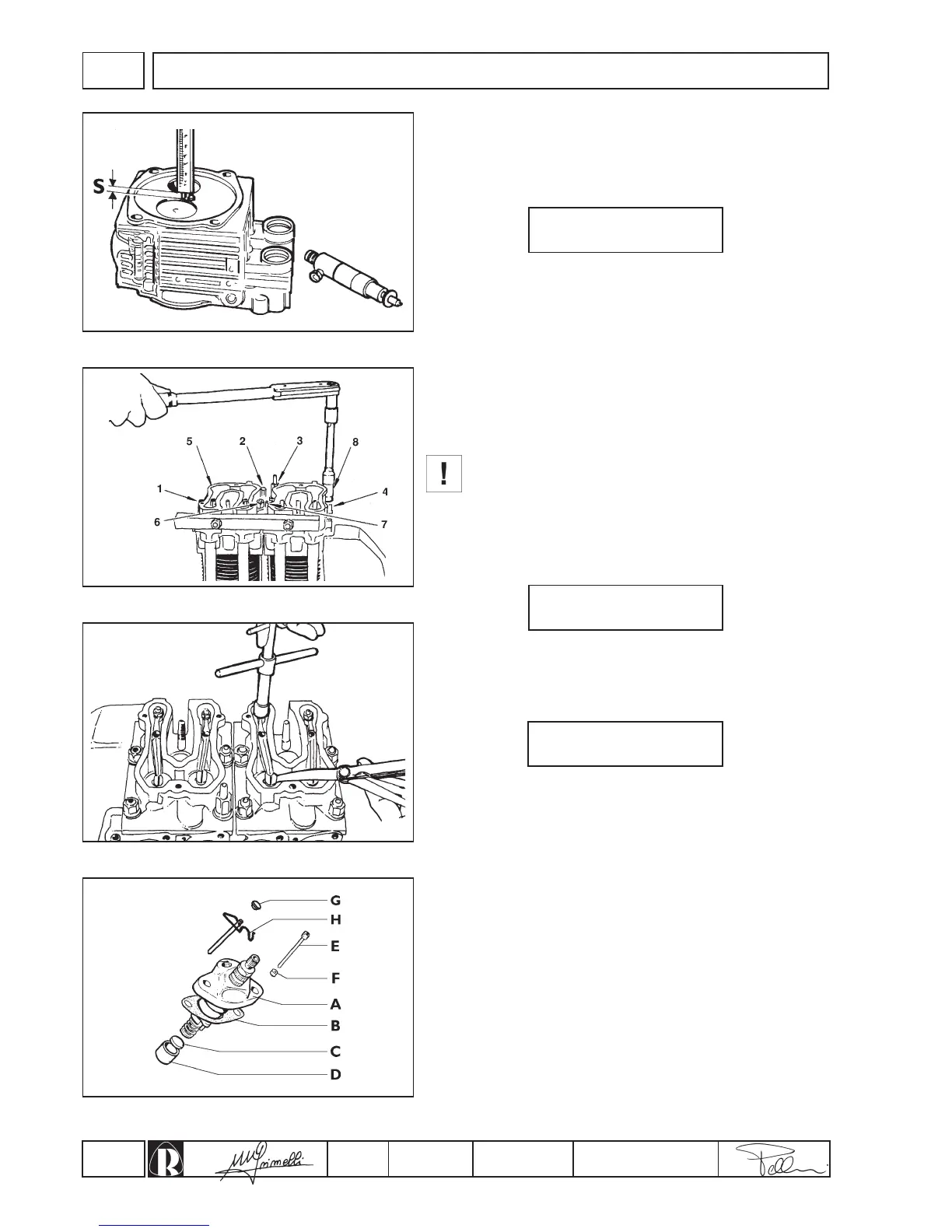

Checking injector protrusion

Before mounting the heads to the cylinders fit the injectors into their

housings and, after having secured them temporarily, check the

protrusion of the nozzles from the head faces (fig.77). Protrusion S

should be:

Cylinder heads

For checking and overhaul of the cylinder heads refer to page 19.

Fit the push rods and oil sealing O-rings on the cover pipes and

proceed to install the cylinder heads with the relative gaskets on the

facing surfaces.

Make sure that the oil seal rings are correctly seated in the

heads to avoid the risk of oil leaks.

Align the heads using a metal bar or the exhaust manifold (fig.78).

Following a cross pattern tighten the head nuts (fig.78) in

increments of 1 kgm until you reach the value:

This value is adjusted by inserting copper washers between the

injectors and the injector supporting faces on the heads (fig. 77).

Valve clearance

The clearance between valves and rockers with the engine cold

(fig.79) is:

This clearance is to be adjusted with the pistons at their respective

TDC compression positions.

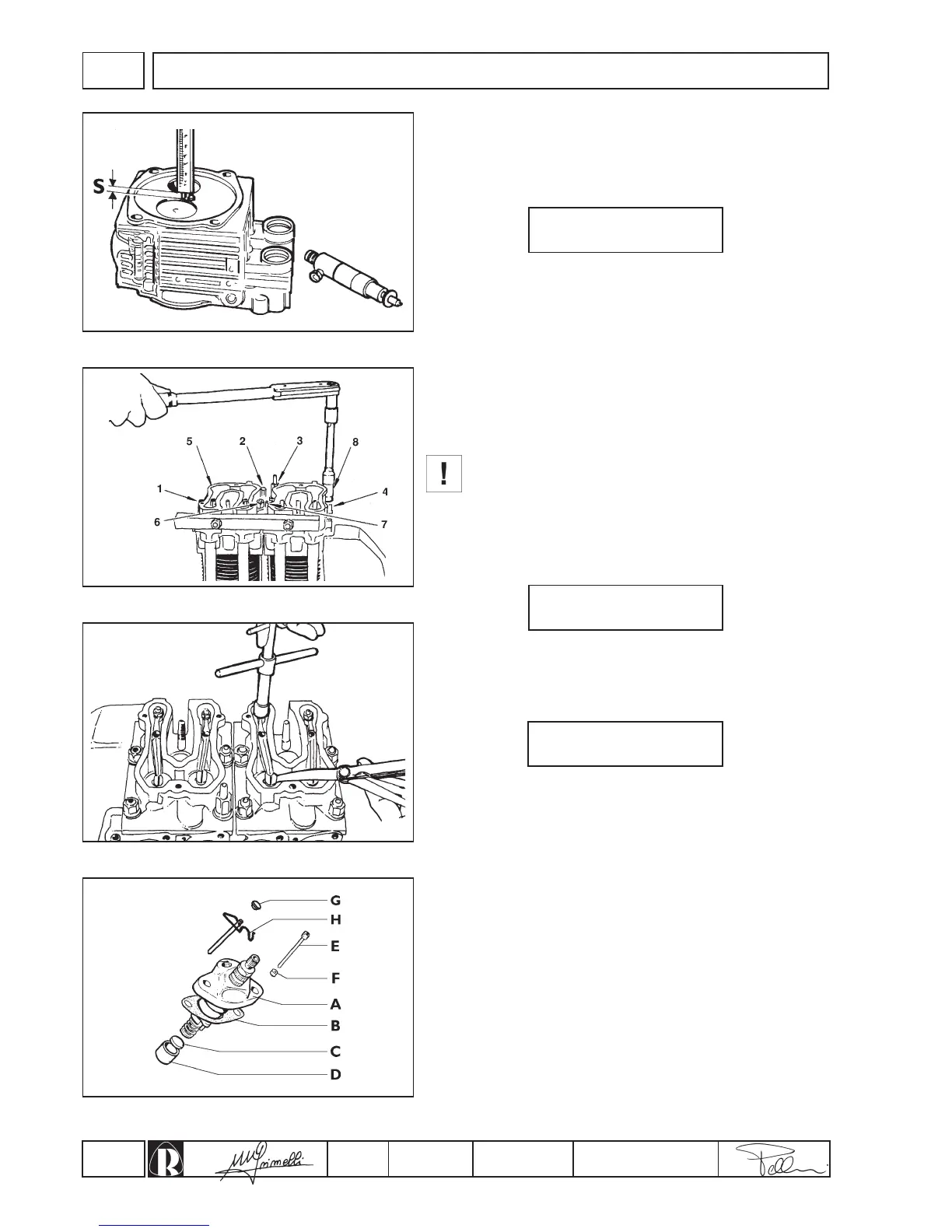

Injection pumps

1.Insert the injection pump tappet (D) and spacer (C) into the

housings in the crankcase (fig.80).

2.Assemble the injection pumps (A fig. 80) on the crankcase and

secure them on the adjustment sleeve by means of the

appropriate pins (E or H fig. 80) on PF30 BOSCH pumps. Then,

place the advance adjustment shims (B, fig. 80) between the

crankcase and the pump.

3.Fix the injection pump connection rod (A, fig.81) to the speed

governor lever tie rod (B, fig.81)

4.Secure the injection pumps to the crankcase, taking care to turn

the first injection pump around through approximately 3/4 of a

turn in a clockwise direction.

intake/exhaust

Loading...

Loading...