36

17-04-2003

01

15-01-2004

DATE

COMPILER TECO/ATI

REG. CODE

1-5302-584

MODEL N°

50871

DATE OF ISSUE

REVISION

ENDORSED

52

51

VIII

53

54

05YR07YR57YR011-301YR

A

30,001÷079,9930,011÷079,90130,011÷79,90130,521÷79,421

B

020,02÷010,02020,02÷010,02020,22÷010,22020,32÷010,32

D

000,02÷599,91000,02÷599,91000,22÷599,12000,32÷599,22

)D-B(

520,0÷010,0520,0÷010,0520,0÷010,0520,0÷010,0

)D-B( .mil

50,050,050,050,0

DISASSEMBLY/REASSEMBLY

When remounting the big-end bearings, remember to

thoroughly clean the parts and generously lubricate them to

prevent seizure when the engine is started up for the first

time

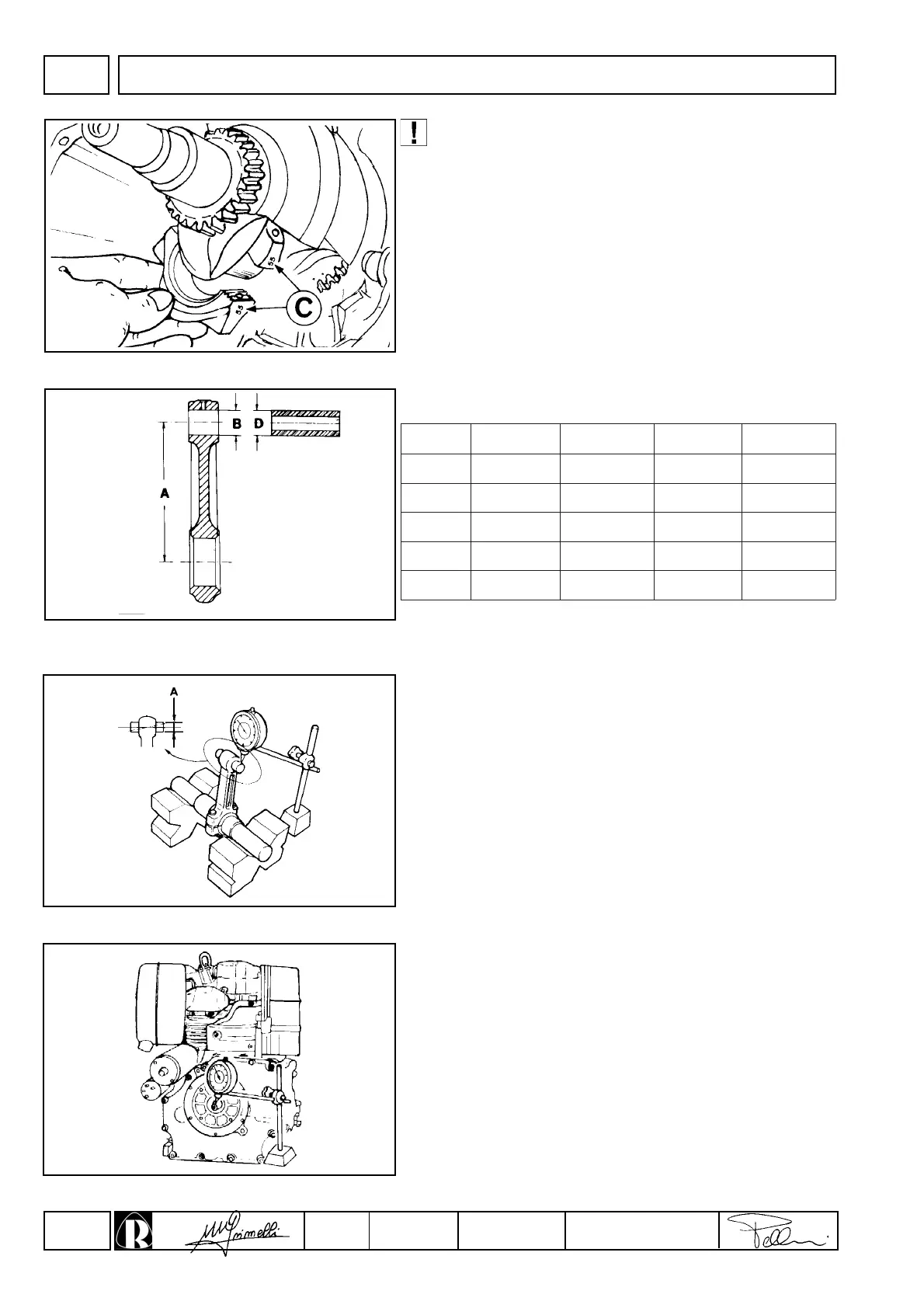

Connecting rod

Demount the connecting rod and proceed with the following

inspections.

The big-end cap and big-end bear the same numbers.

When remounting, mount the cap from the same side as in C of the

figure.

Tighten the RY 50 bolts to a 23 Nm torque value.

Tighten the bolts to a 30 Nm torque value for RY 70-75-103-110.

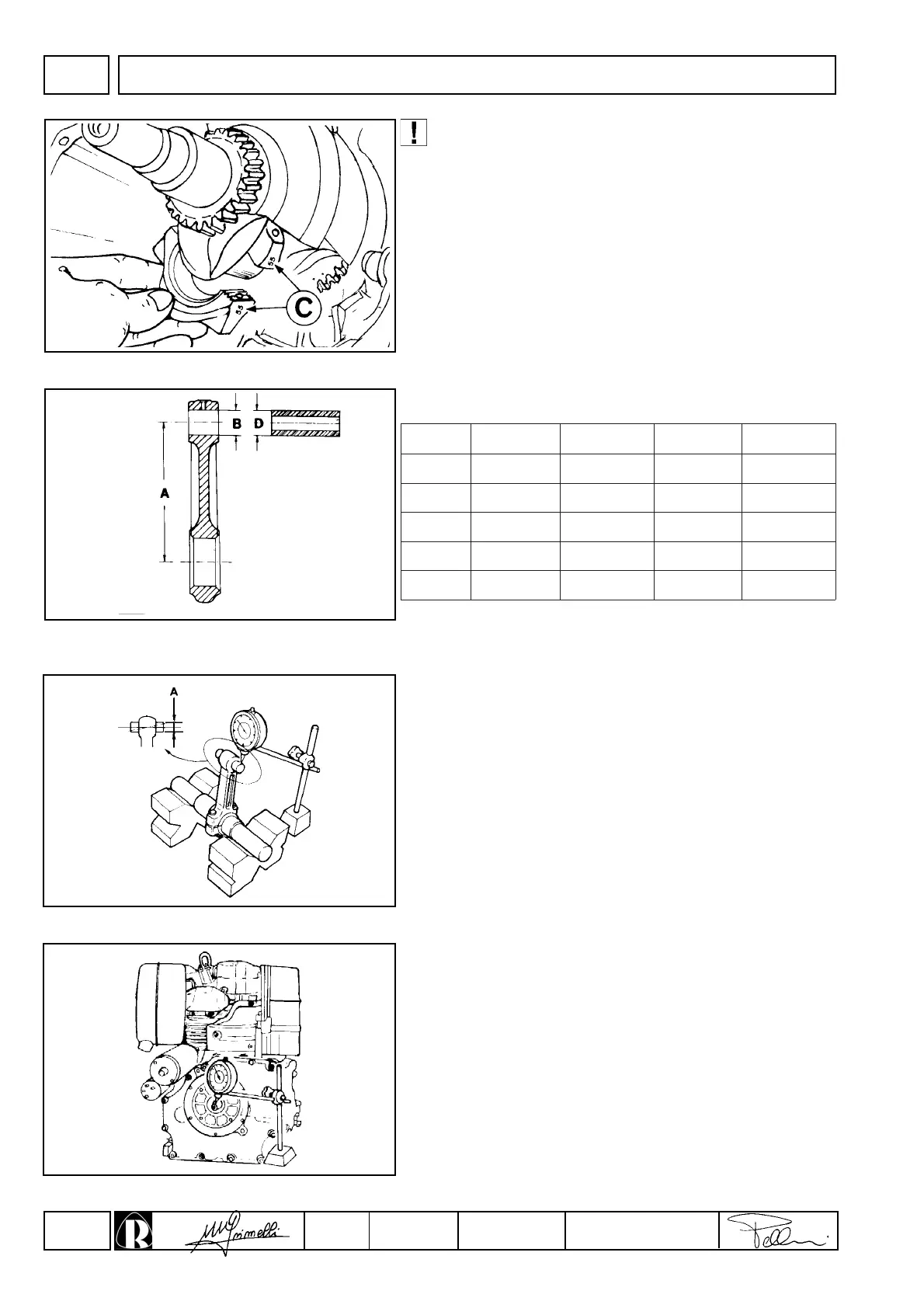

Connecting rod, piston pin

Note: The connecting rod has no insert bearings. See fig. 62 for

connecting rod big end diameter.

Connecting rod alignement

Use a dial gauge as shown in the figure.

Check that axes are aligned using the piston pin; axial

misalignment A = 0.015; limit 0.03 mm.

Crankshaft end play

Secure the engine to a metal base or table. Use a dial indicator with

column and magnetic base plate. Place the stylus on the crankshaft.

Move the driving shaft back and forth on the flywheel side.

End play should be 0.05 - 0.25 mm; it is not adjustable.

Loading...

Loading...