20 DRUM MOTOR INSTALLATION MANUAL 80LP-138LP

REPLACEMENT PARTS AND ACCESSORIES

Mounting Brackets

F = F1 + F2 + F3 +....

Friction

between belt

and Material

Weight (t)

Bell Pull =

•

F (N)

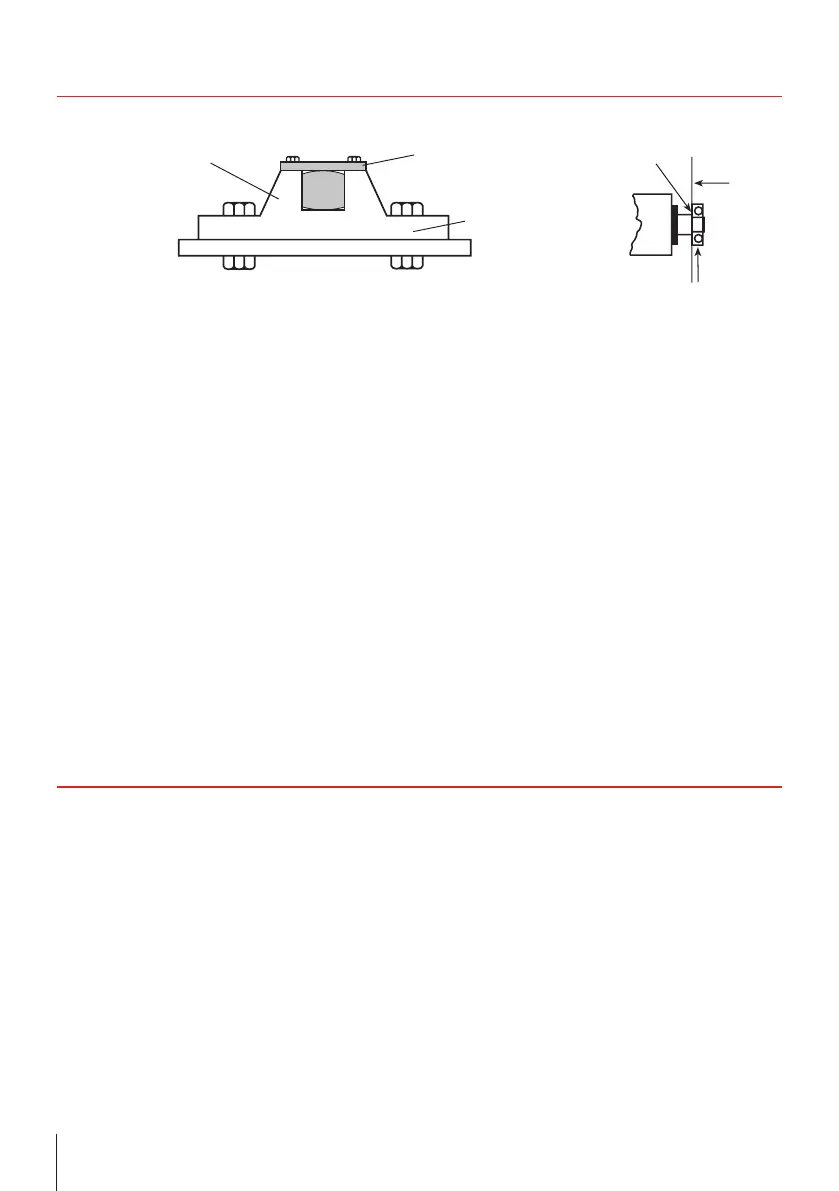

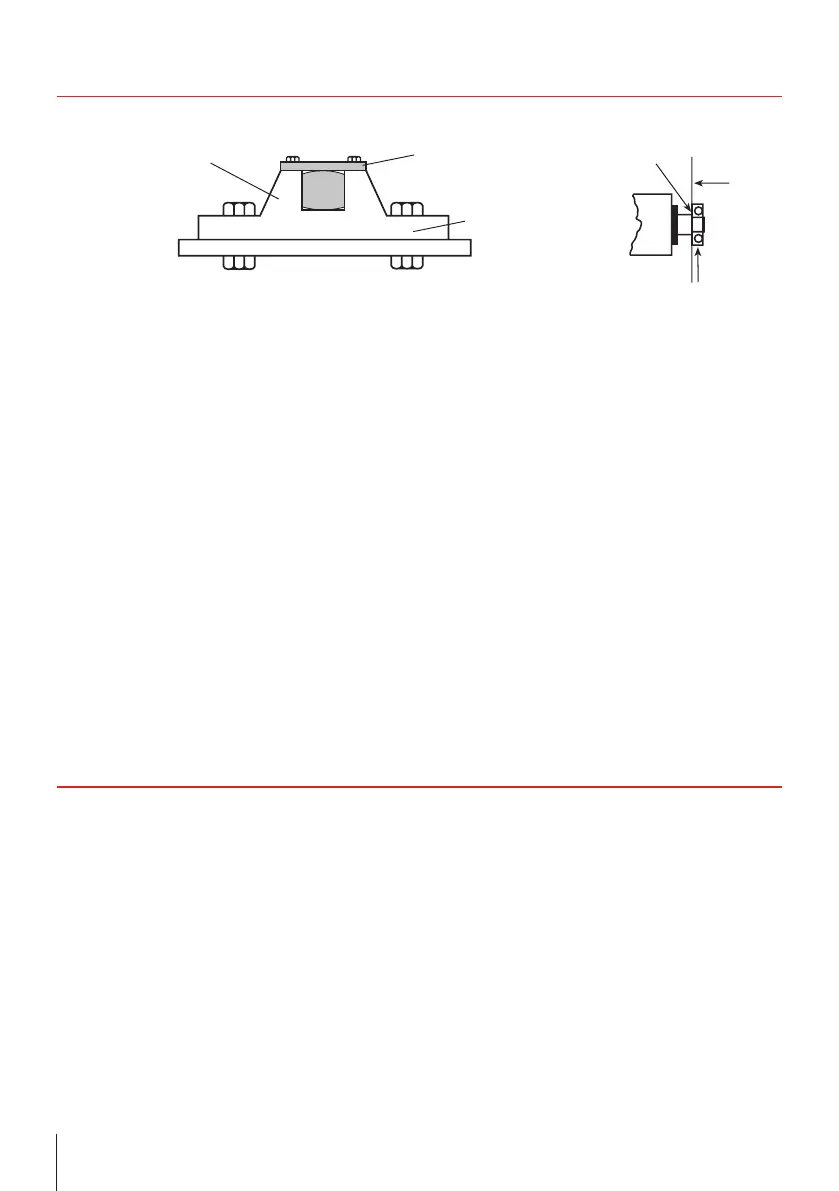

Shoulder Retaining plate

Base

Shaft shoulder

Bracket

Bracket

with key

Key

Marking of the

earth screw

R, S, T

PEN

K1

K

TP

M

3

F = F1 + F2 + F3 +....

Friction

between belt

and Material

Weight (t)

Bell Pull =

•

F (N)

Shoulder Retaining plate

Base

Shaft shoulder

Bracket

Bracket

with key

Key

Marking of the

earth screw

R, S, T

PEN

K1

K

TP

M

3

> Use only the mounting brackets that match the

respective Drum Motor type.

> Assemble mounting brackets to the frame so

that the shoulder or base resist belt tension.

When RULMECA Drum Motor mounting

brackets are NOT used, it is essential that:

• the mounting equipment supports at least 80 %

of the shaft ats.

• the clearance between the shaft ats shoulder

and the support is less than 0.4 mm (torsion

play).

• there is no clearance between the bracket and

the shaft shoulder.

A Drum Motor with frequent reversals or start/

stops should be mounted without axial clearance

between the shaft at shoulder and the bracket.

Motor Thermal Protection

All Drum Motors are supplied with a built-in thermal

protector.

• heat-sensitive, bi-metallic switches built into

each motor phase winding

• maximum permissible current 2.5 A

• voltage 230 V

> Connect the switches to the closed control

circuit (in series with a magnetic coil/relay device

and contactor)

• The switch opens if motor temperature rises to

an excessively high level.

> The motor will shut down.

• The switch will automatically close once the

motor has cooled down.

• Cooling time = 30 – 60 min at an ambient

temperature of 20 °C

> Use this period of time to identify the reason

for the shutdown.

> Do not operate the motor until the causes of

the overheating/overload have been eliminated.

Lagging

Lagging thickness and width greatly affect Pulley

heat dissipation characteristics.

Basic specications:

• Smooth, diamond pattern

• Black, white synthetic rubber

• shore hardness A = 65 or 70 durometer

• cold-bonded or hot vulcanised

Optional hot vulcanized lagging is available for high

power/high torque/high temperature applications.

> Contact the belt supplier if belt/lagging material

compatibility may be a problem.

Belt

The belt type, the belt thickness and the correct

pulley diameter must be determined according to

the belt manufacturer’s data.

Belt tension

> Do not over-tension the belt.

> Tension the belt just enough to prevent the belt

from slipping and to ensure non-slip operation.

The maximum permissible belt tension (T1 + T2) is

specied in our catalogue.

Loading...

Loading...