22 DRUM MOTOR INSTALLATION MANUAL 80LP-138LP

APPENDIX

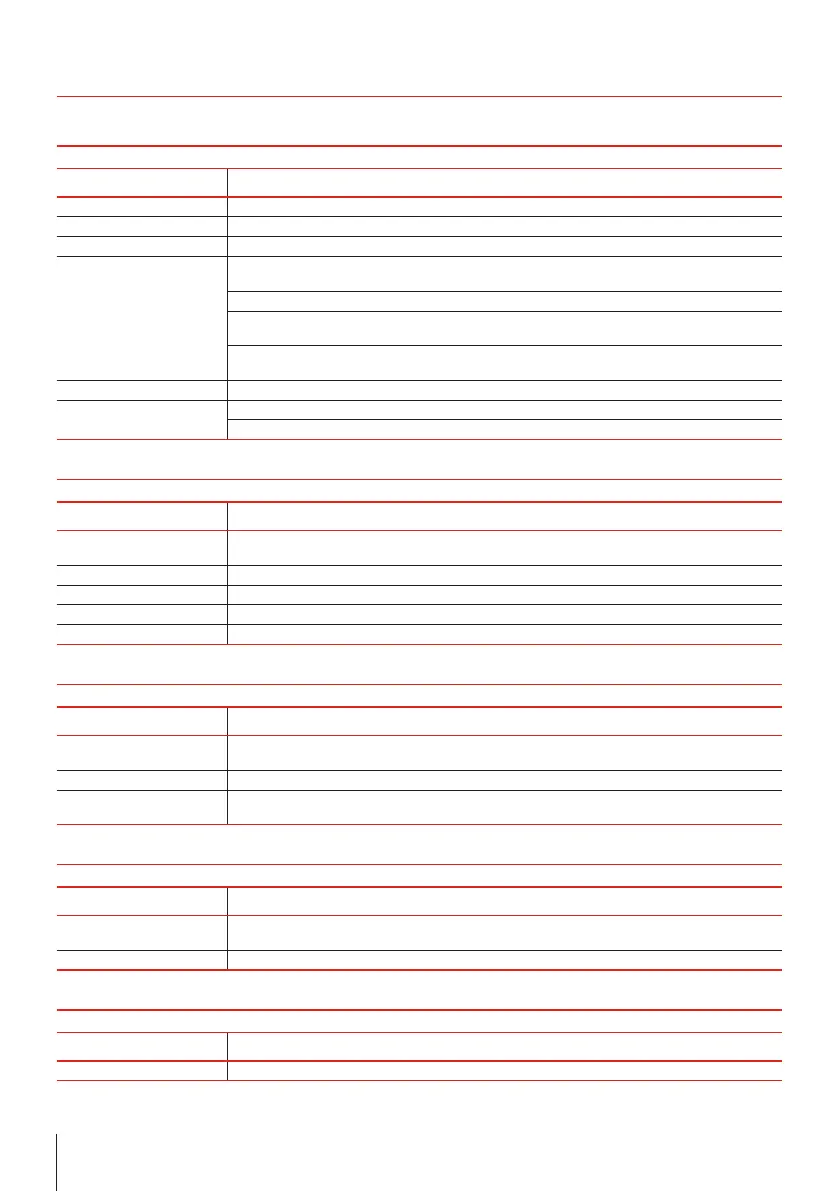

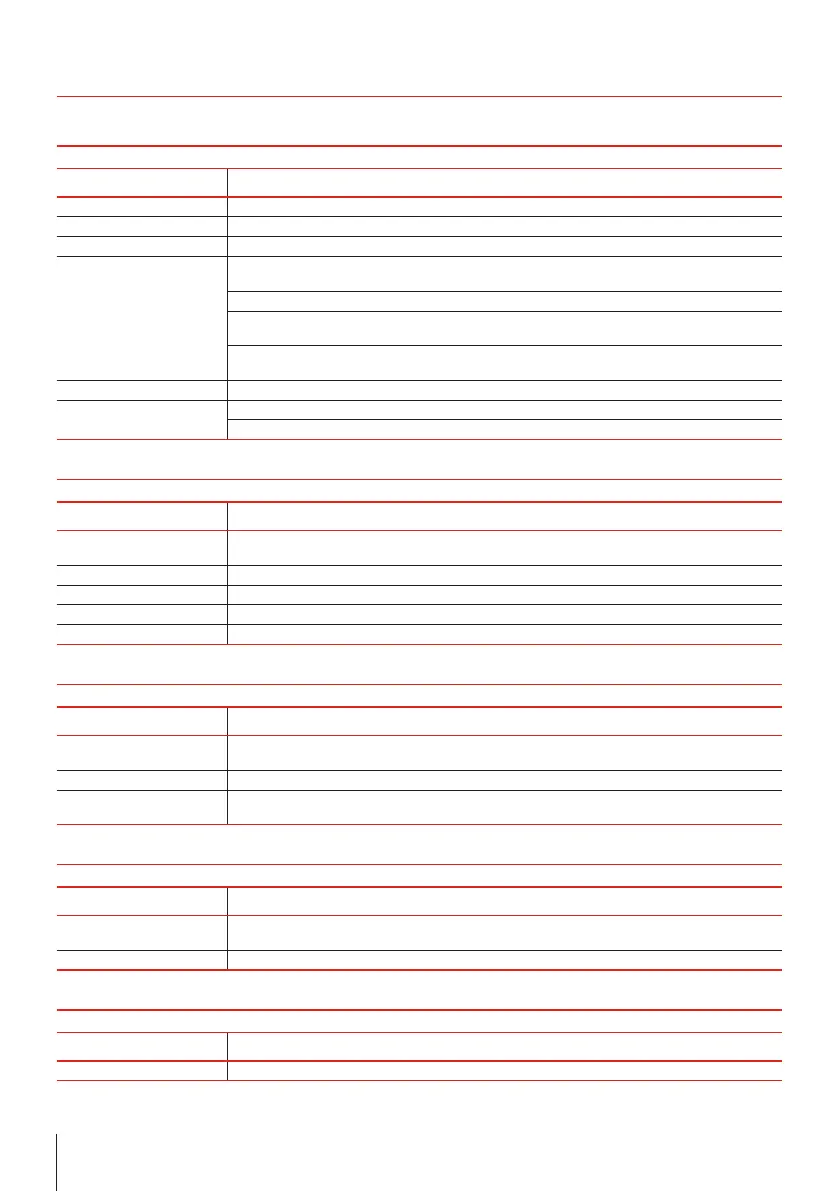

Troubleshooting

MOTOR STOPS OR DOES NOT START

Cause Solution

Incorrect connection Check the connection according to the wiring diagram. Check if wires

No power supply Check power supply

Overload Switch off power and check and eliminate the cause of the overload

Motor overheated

- Motor power too low. Compare the application requirements with the drum motor

specications.

- Lagging too thick. Replace friction lining.

- Incorrect inverter setting. Check and adjust settings according to drum motor

specications.

- Too many frequent start/stops. Reduce number of start/stops or use an inverter for

optimized operation.

Incorrect capacitor - Check if capacitor size is correct. Use the appropriate capacitor.

Short circuit Return the drum motor to RULMECA for inspection.

Replace drum motor

NOISY DRUM MOTOR OPERATION

Cause Solution

Excessive play on

mounting

Check mounting. Assemble the motor without any clearance between the support and

the shaft.

Incorrect inverter setting Check and adjust settings according to the drum motor specications.

Loose wire Check connection

Incorrect capacitor check if capacitor size is correct

Gearing damaged Return the drum motor to RULMECA for inspection.

EXCESSIVE DRUM MOTOR VIBRATION

Cause Solution

Excessive play on

mounting

Check mounting. Assemble the motor without any clearance between the support and

the shaft.

Incorrect inverter setting Check and adjust settings according to the drum motor specications.

Motor running without

belt

Run the drum motor with tted and tensioned belt.

DRUM MOTOR RUNS FASTER OR SLOWER THAN SPECIFIED

Cause Solution

Incorrect drum motor

speed ordered

Check required specications and replace drum motor

Incorrect inverter setting Check and adjust settings according to the drum motor specications.

DRUM MOTOR IS LEAKING OIL

Cause Solution

Excessive belt tension Send the drum motor back to RULMECA for inspection

Loading...

Loading...