MODEL: 63518-N77A1 /63618-N77A3/ 53518-N77B1

40

clean or replace turbine.

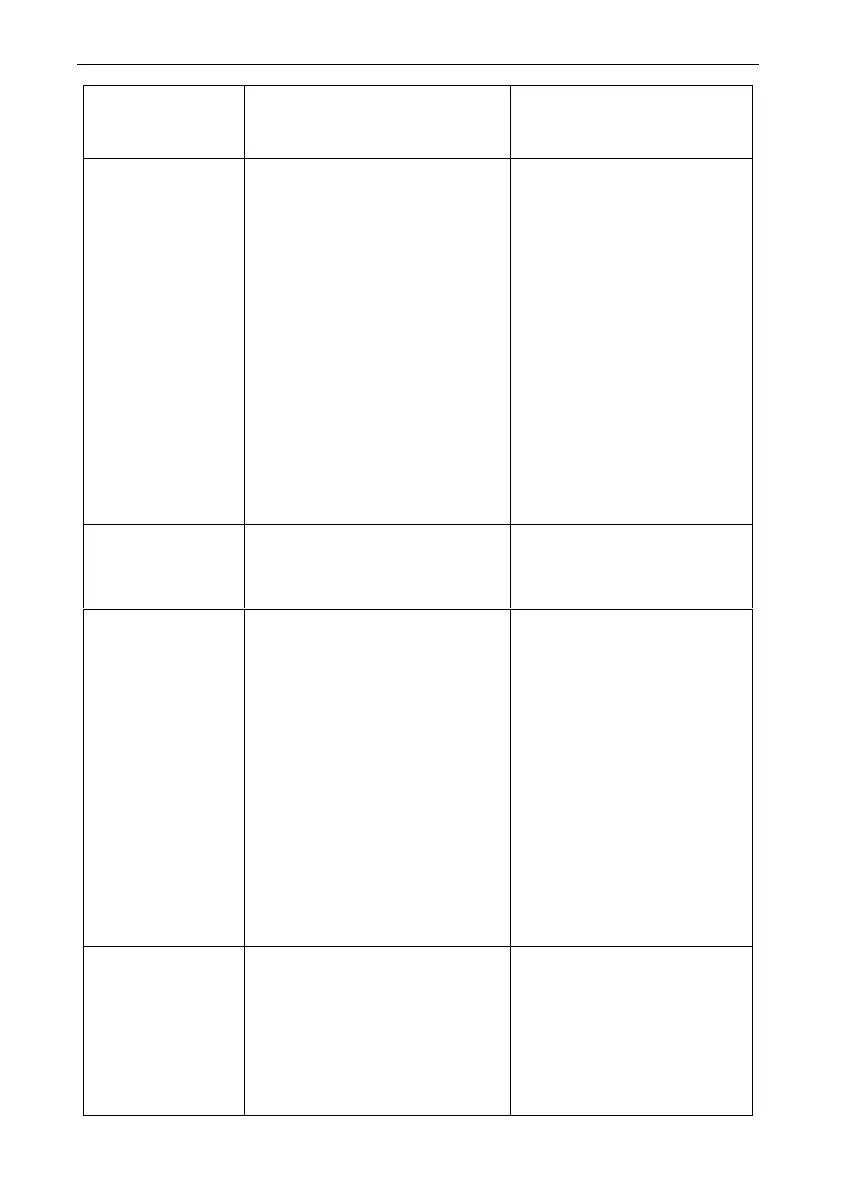

4. Softener fails

to draw brine.

A. Line pressure is too low.

B. Brine line is plugged.

C. Brine line is leaking.

D. Injector is plugged.

E. Internal control leak.

F. Drain line is plugged.

G. Sizes of injector and DLFC

not match with tank.

H. Ball valve or cable failure

A. Increase line pressure.

B. Clean brine line.

C. Replace brine line.

D. Clean or replace new

parts.

E. Replace valve body.

F. Clean drain line flow

control.

G. Select correct injector

size and DLFC according to

the P29 requirements.

H. Replace ball valve or

cable

5. Unit used too

much salt.

A. Improper salt setting.

B. Excessive water in brine

tank.

A. Check salt usage and

salt setting.

B. See problem no.6.

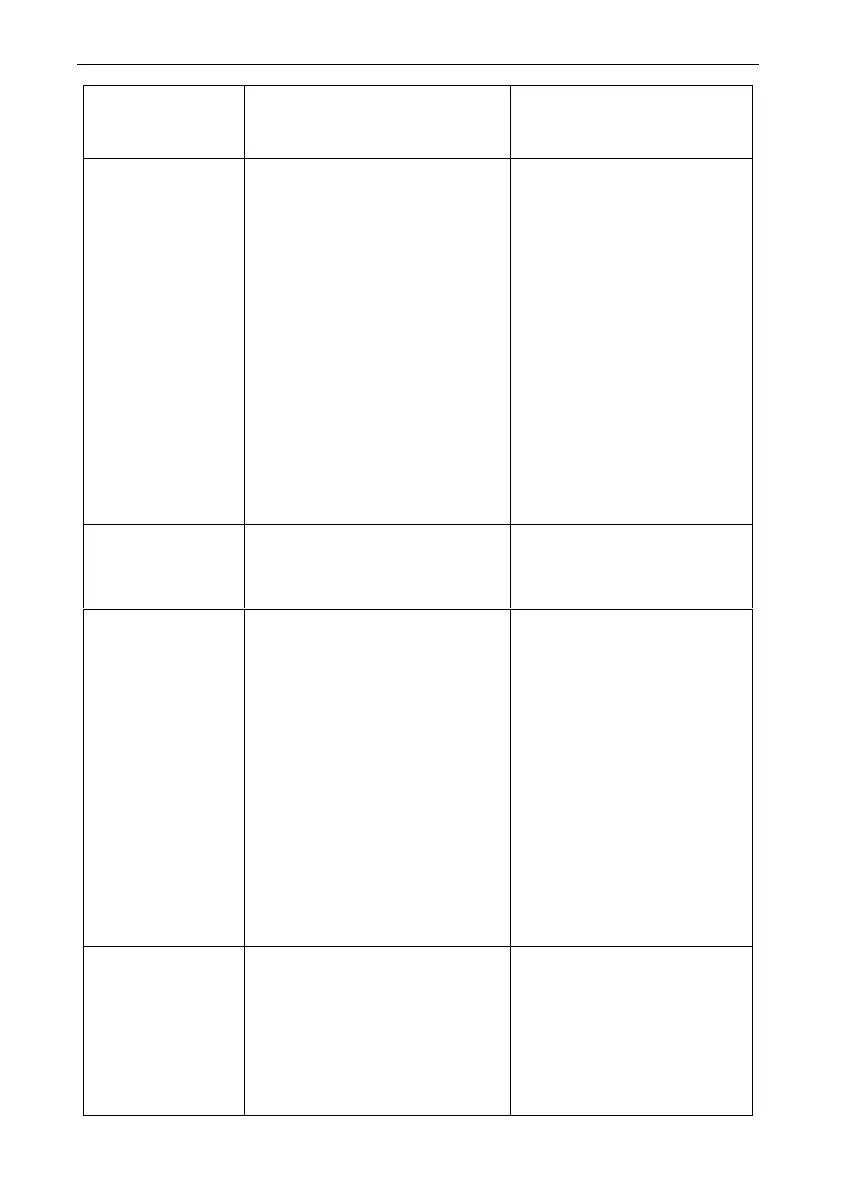

6. Excessive

water in brine

tank.

A. Overlong refilling time.

B. Foreign material in brine

line.

C. Foreign material in brine

valve and plug drain line flow

control.

D. Not install safety brine valve

but power failure whiling

salting.

E. Safety brine valve

breakdown.

F. Ball valve doesn’t close

A. Reset correct refilling

time.

B. Clean brine line.

C. Clean brine valve and

brine line.

D. Stop water supplying

and restart pr install safety

brine valve in salt tank.

E. Repair or replace safety

brine valve.

F. Close or replace ball

valve or cable

7. Pressure lost

or iron in

conditioned

water.

A. Iron in the water supply

pipe.

B. Iron mass in the softener.

C. Fouled resin bed.

D. Too much iron in the raw

water.

A. Clean the water supply

pipe.

B. Clean valve and add

resin cleaning chemical,

increase frequency of

regeneration.

Loading...

Loading...