BA.GB.12-27409-05-07-FTA-jr

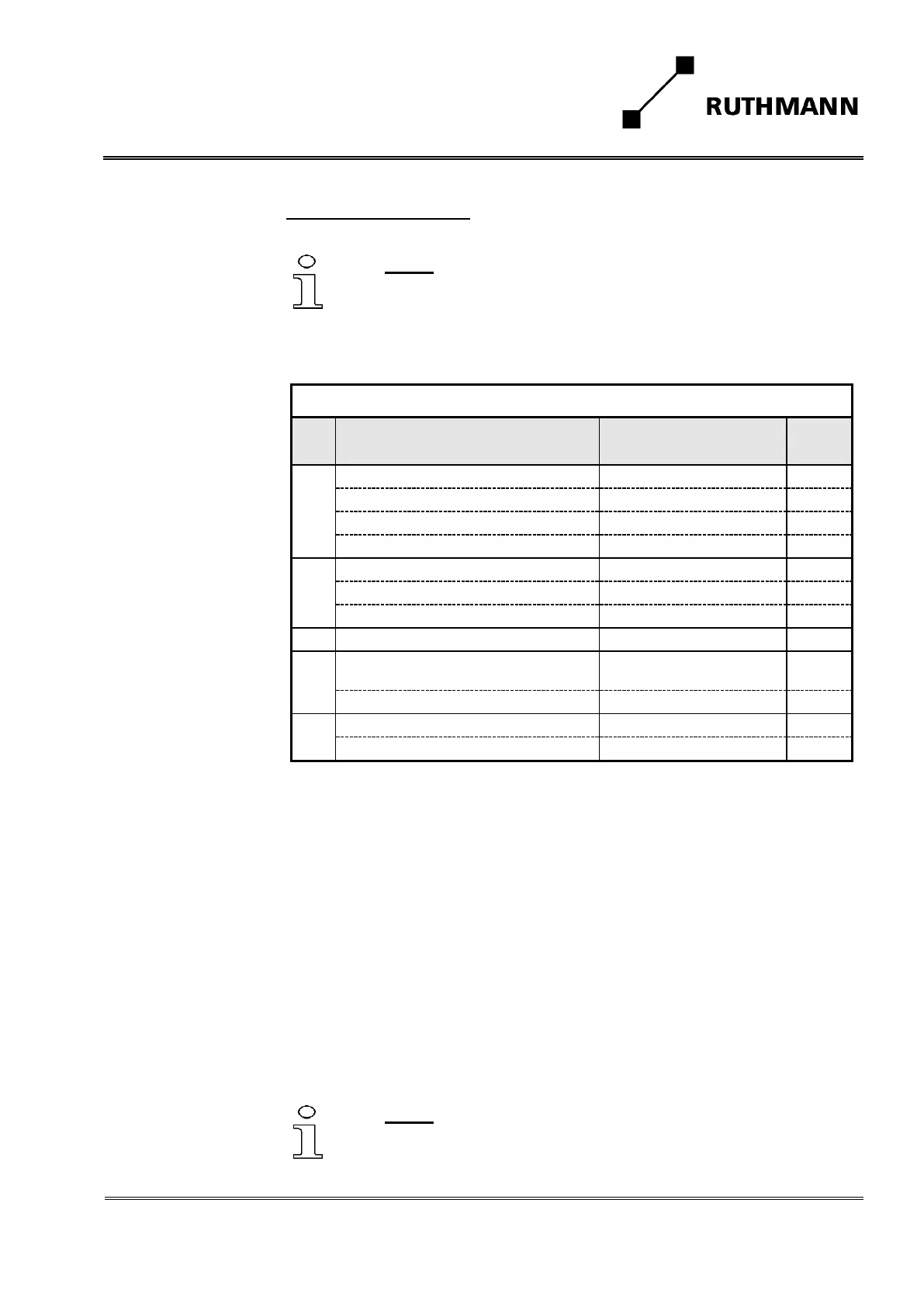

9.1.2 Lubricating point list

Note

Before greasing the grease nipples must be cleaned. Re-

marks concerning execution of inspection and maintenance

work please see chapter 9.4.5.

Component / Lubricating point

Lubricant used in our

work (Part-No.

1

)

Jacking / guidance jack cylinder

Jacking / gliding surfaces of jack arm

Jacking / ground contact inquiry

Jacking / hinged foot (joint of jack plate)

Boom / gliding surfaces of telescope

Rotating device / ball bearing slewing

gear

Rotating device / worm gear

Hydraulic oil in system (standard)

Hydraulic oil in system (optional extra)

1

Ruthmann-Part-No.

If other lubricants are used an evaluation concerning the aggressivity of the

greases and oil compared with the constructional components used by us

must be carried out. If lubricants are mixed with each other the acceptabil-

ity of the lubricants

under each other,

to light metal and non-ferrous heavy metals,

to plastics,

to anticorrosive and preservatives

must be checked.

Note

We recommend using if possible that lubricant which had

Loading...

Loading...