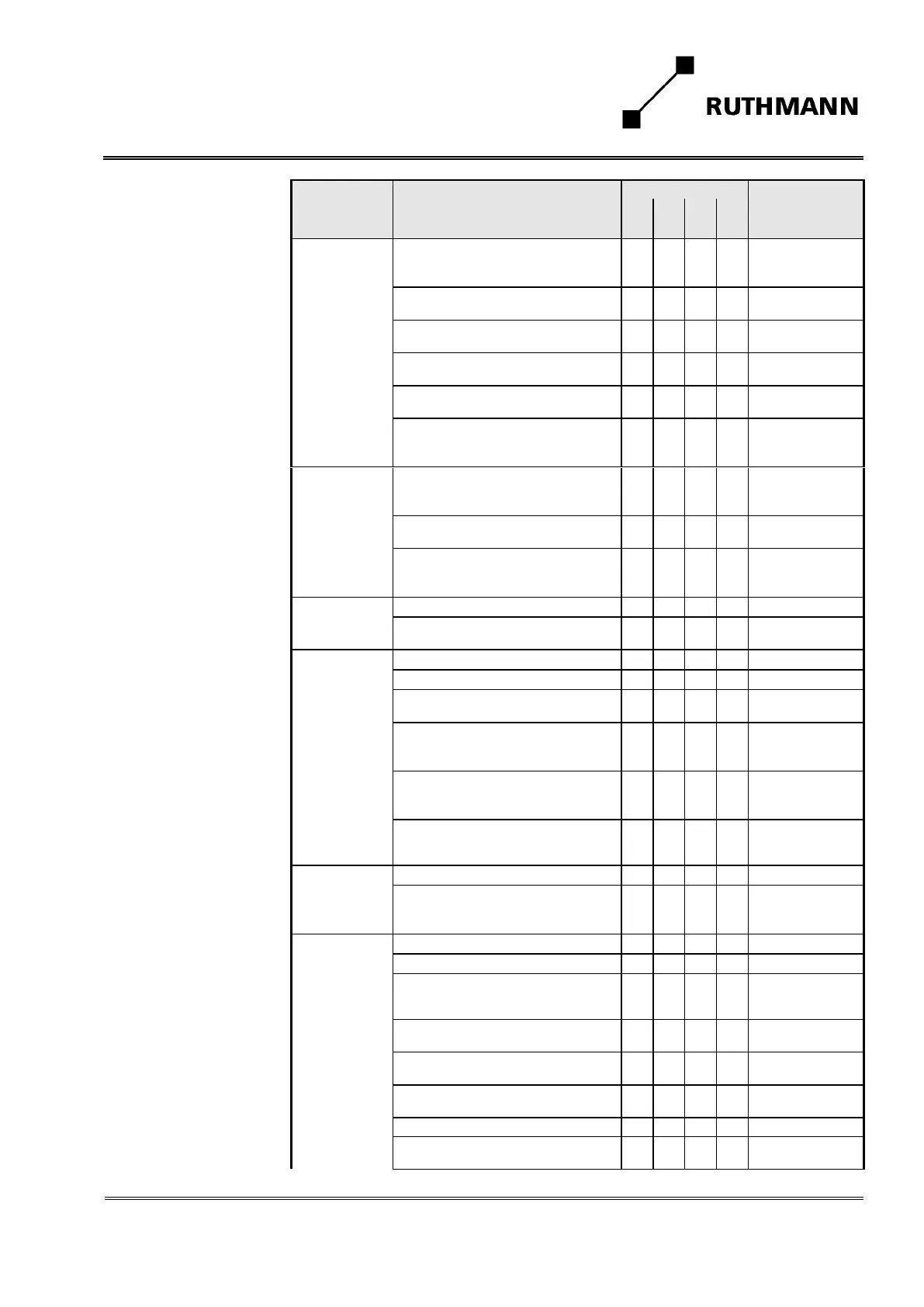

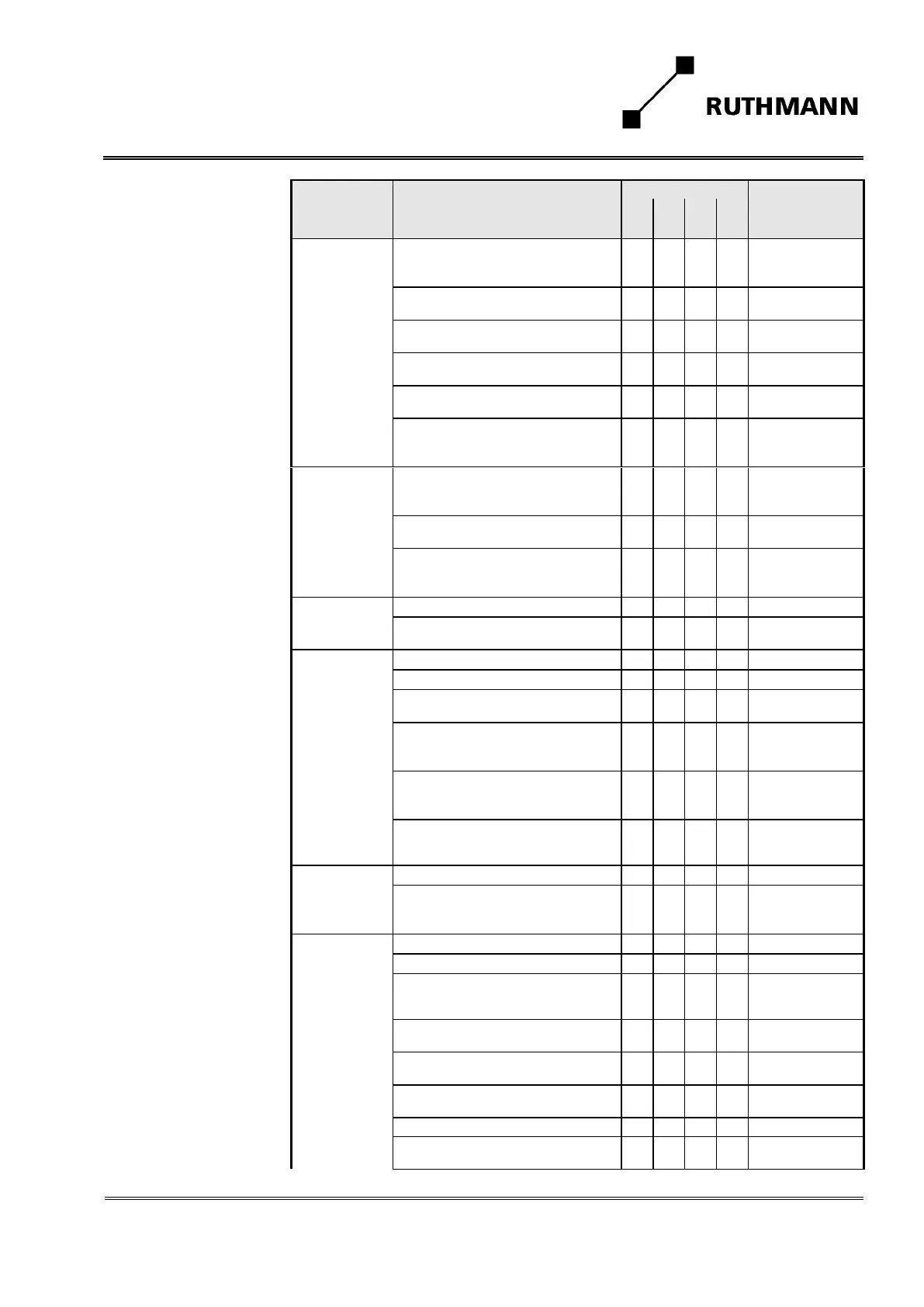

BA.GB.12-27409-05-07-FTA-jr

Check free spaces for movement

sequences of mech. and hydr.

constr. components

Check free spaces for movement

sequences of power track

Check power tracks for fastening

and damage

Check fastening of removable

connections for firm hold

Check superstructures for fas-

tening and damage

Check covering of roof of driver’s

cab (optional extra) for fastening

and damage

, firstly after three

months

Bearing points

and bolt locks

(Ruthmann-

Check bearing points with plastic

bushes and screw fittings of bolt

locks

Check other bearing points as well

as bolt locks and its screw fittings

Bearing points with DU-bushes

clean and grease or cover dividing

points / contact surfaces with oil

if grease nipple

provided grease

bearing point

Check tear at guiding device

Clean and grease gliding surfaces

of jack arms

Ground contact interrogation:

Grease the screw pressure spring,

bolt and the oblong hole bearing

Guiding device jack cylinder:

Clean and grease the area of the

guide rings

Jack plate

Grease hinged presser foot

W, if necessary

after cleaning of

the Steiger

Check baffles and guiding devices

of the chains for power track for

wear

Check tear at guiding devices

Grease telescope gliding surfaces

W, if necessary

after cleaning of

the Steiger

Check prestressing of retraction

chains and extension ropes

Check ropes for surface corrosion

and damages

Check wear at the rope groove of

the rope roller

Check chains for surface corrosion

and link corrosion

Loading...

Loading...